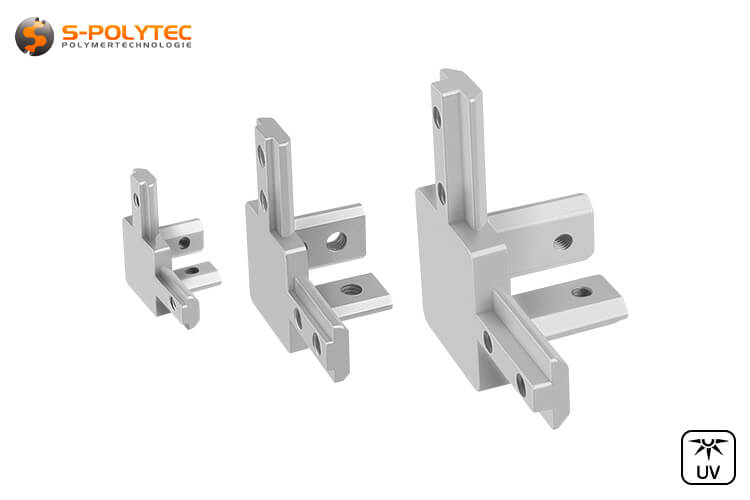

3-way corner connector for construction profiles

The 3-way corner connector made of rustproof die-cast zinc is used for the simple assembly of three construction profiles arranged at right angles to one another and also serves as a cover for the cut edge.

✓ Rustproof die-cast zinc

✓ stable corner joints

✓ Very easy to assemble

✓ Optimum edge coverage

✓ Including grub screws

✓ For indoor and amp; outdoor use

The profile connectors are available in different sizes to match our construction profiles.

The item is in stock

Dispatch within 2-3 working days

- calculate the price

- from 10 Items €3.00/ pc. (Base Price €3.00/ pc.)

- from 20 Items €2.80/ pc. (Base Price €2.80/ pc.)

- from 50 Items €2.70/ pc. (Base Price €2.70/ pc.)

All prices include 19% VAT.

0,00 € / pc.

0,0000 kg / pc.

All prices include 19% VAT.

- Description

3-way profile connector made of rustproof die-cast zinc

Stable connection ✓ Including grub screws ✓ Also suitable for outdoor use ✓

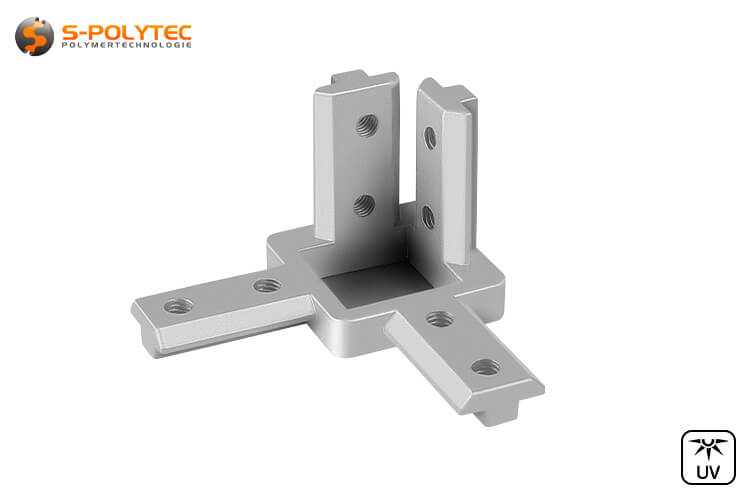

Our 3-way profile connectors for construction profiles are used to connect three profiles of the same size, each arranged at 90° to one another, and are available to match our system profiles in sizes 20x20mm, 30x30mm and 40x40mm. The solid metal connectors are finished in an attractive silver colour that perfectly matches the look of the silver construction profiles. The rounded corners, which are characteristic of I-Tys construction profiles, including our slot profiles, fit perfectly with the outer contours of the respective profile, so that the cut edge is perfectly covered. This also has an effect on the visual quality of a construction. The cut edge covering also protects against injuries from the usually sharp saw edges. Furthermore, the edge covering prevents damage to sensitive floor coverings caused by open profile edges. It is installed by inserting it onto the cut edge of the construction profile and is then screwed tight using the grub screws included in the scope of delivery and a standard Allen® key.

3-way profile connectors are ideal for all cuboid structures that are to be created with groove profiles. These include table frames, storage and shelving systems, transport cases, vertical gardens for indoor plants, or even frames for machines or free-standing outdoor canopies. Thanks to the use of rustproof die-cast zinc, the connecting elements are characterised by excellent UV and weather resistance.

NOTE: No special tools are required to attach the construction profiles to the connector. A simple Allen® key is sufficient, the size of which varies depending on the design. The matching grub screws with internal hexagon drive are already included in the scope of delivery, so that assembly can take place without delay.

Properties of our three-way corner connector

The silver 3-way angle connectors for internal profile connection are available to match our construction profiles in the versions 20x20mm, 30x30mm, and 40x40mm and have the rounded corners typical of I-type system profiles, whose corner radius matches that of our construction profiles. The solid production using the die casting process ensures a secure and firm screw connection of three identical profiles, each arranged at an angle of 90° to one another, making them ideal for all cubic or cuboid basic constructions. The metal connectors also improve the appearance, because the silver surfaces form a perfect finish on all three profiles, which are connected to each other in this way without the cut edges of the construction profiles being visible. Furthermore, the risk of injury and damage to scratch-sensitive floor coverings is considerably reduced by covering the usually sharp-edged cut ends with the 3-way connector made of die-cast zinc.

Zinc die casting is an extremely corrosion-resistant metal alloy characterised by high strength and stability. The combination of these properties therefore also allows for the construction of load-bearing substructures and frames in humid environments or outdoors. Possible applications would be the construction of individual patio furniture, raised beds, small greenhouses or even shelters for rubbish bins, bicycles and garden tools, attractively clad and roofed with opaque facade panels.

The dimensions of the 3-way corner connectors refer to the edge width of the respective construction profiles and do not take into account the groove connecting bridges, as these are inserted into the profile groove and thus do not affect the overall size of the construction. Only the installation height of the flat connector side must be taken into account in the case of constructions whose external dimensions are to be adhered to with millimetre precision. This is approx. 4.7mm for the 20 mm connector. The 30mm 3-way profile connector adds a height of 5.8mm and the large version for 40mm construction profiles extends the profile length by approx. 9.2mm. The small version is provided with an internal thread for holding the grub screw at each groove connecting bridge. The two larger versions, on the other hand, each have two holes with an internal thread. The appropriate grub screws are always supplied in the appropriate quantity (4 or 8 pieces). These also differ in diameter, length and size of the drive with internal hexagon depending on the specific design of the profile connector.

NOTE: The 3-way corner connectors are only suitable for connecting identical square construction profiles with open grooves. It is not possible to combine different construction profiles, for example a 40mm profile and two 30mm profiles. In this case, you should use mounting brackets with matching slot nuts or hammer head screws.

Specific data of the corner connector

- 3-way corner connector for 20x20mm groove 6: Dimensions: 20mmx20mm, groove width: groove 6, grub screw: M3x6mm (HEX2), weight: 27g

- 3-way corner connector for 30x30mm groove 8: Dimensions: 30mm x 30mm, groove width: 8, grub screw: M5x8mm (HEX3), weight: 73g

- 3-way corner connector for 40x40mm groove 8: Dimensions: 40mmx40mm, groove width: groove 8, grub screw: M5x10mm (HEX3), weight: 172g

Mounting of application of hinges made of die-cast zinc on construction profiles

The construction of structures with construction profiles that have to be arranged at right angles to each other in three directions can best be realised with a 3-way corner connector. This requires the profiles to be cut in straight lines and only an Inbu® key in 2mm or 3mm is required for assembly to tighten the grub screws. To do this, the profiles are pushed onto the corner connector with the groove and the grub screws are screwed into the internal thread of the connector until a firm connection is created.

For simple constructions that are only subject to low mechanical loads from vibrations or movement, for example for shelving systems or patio furniture, connecting the profiles with the 3-way corner connector made of diecast zinc is perfectly adequate. For machine constructions, the additional use of two inner corner connectors on the inner side of the corner connection can significantly increase stability and load-bearing capacity. In this case, however, the inner corner connectors should be inserted into the two remaining grooves of the profile before mounting the 3-way connector, whose cut edge is covered by the integrated cover, because after the connector has been screwed on, the inner corner connectors can no longer be inserted into the groove. Alternatively, our mounting brackets, which can be mounted at any time using hammer-head screws or sliding nuts, serve as an effective method of achieving a highly durable corner connection.

NOTE: To achieve a flawless transition from the connector to the three profiles, we recommend cutting the aluminium profiles with a crosscut saw with a blade that is suitable for aluminium. Deburring the cut edge can also improve the appearance. This ensures that the profiles are flush with the corner cover of the profile connector.

Examples of how our rustproof external corner connectors can be used

- The 3-way corner connectors are ideal for the frames of garden tables made of construction profiles

- In transport cases made of aluminium profiles, the usually sharp outer corners are completely covered

- Combined with inside corner connectors, highly durable connections for heavy machine constructions are created

- The corner connector also serves as a cover cap and protects delicate floors from sharp saw edges

- For sales shelves or shelves in dressing rooms, the corner profile connectors significantly enhance the appearance

Technical data of the 3-way corner connector

- Material (connector): Zinc die casting

- Material (installation material): Carbon steel (nickel plated)

- Colour: Silver

- Angle: 90°

- Groove width: Groove 6 resp. groove 8

- Assembly: internal

- Installation material: Grub screws (included)

- Weight: 27g-172g

- UV-resistance: Excellent

- Weather resistance: Excellent

- Corrosion resistance: Sufficient

- Additional Information

Additional Information

Product-ID 3WV-0000 Delivery Time Dispatch within 2-3 working days Property 3-way corner connector Material Zinc die casting Color Silver - Reviews