37mm Alu-Adjustmentprofile (slat dowel)

The aluminium adjustment profiles are used to compensate for height differences in different floor coverings both indoors and outdoors. Thanks to concealed installation with flexible slat dowels, the finely grooved surface remains visually unaffected.

✓ Finely grooved surface

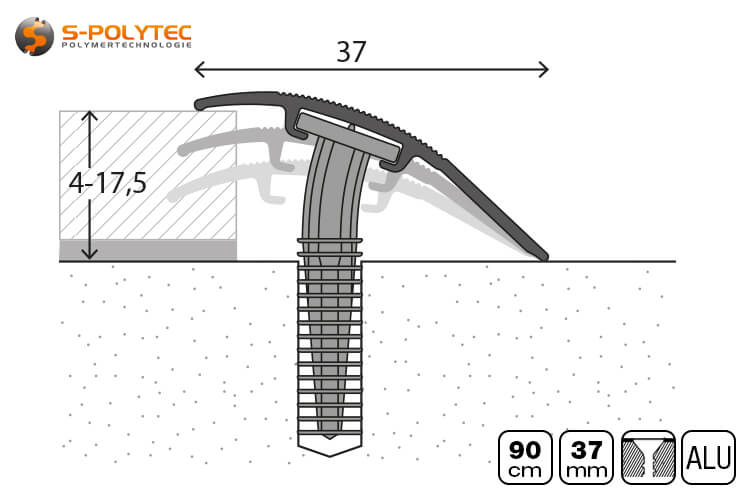

✓ Up to 17.5mm height compensation

✓ For indoors & outdoors

✓ Concealed dowel installation

✓ Incl. slat dowels

✓ Shrink-wrapped

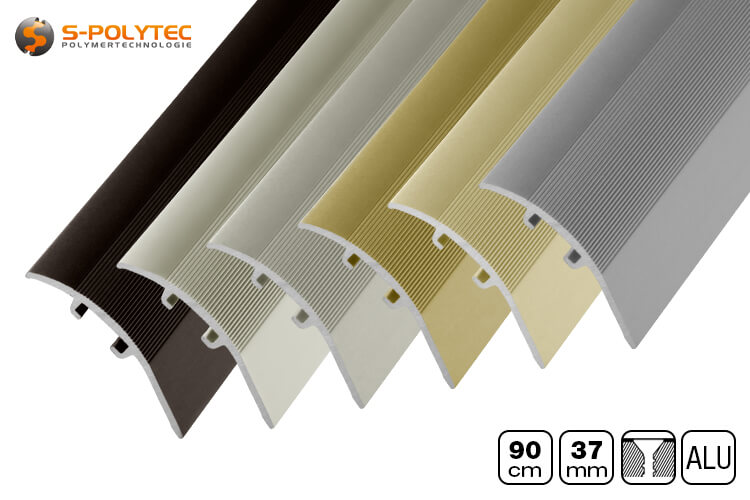

The aluminium adjustment profiles from us are available in the colours silver, sahara, gold, bronze, matt or polished stainless steel.

The item is in stock

Dispatch within 2-3 working days

- calculate the price

- from 5 Items €10.35/ pc. (Base Price €11.50/ m)

- from 10 Items €9.84/ pc. (Base Price €10.93/ m)

All prices include 19% VAT.

0,00 € / pc.

0,0000 kg / pc.

All prices include 19% VAT.

- Description

37mm adjustment profile for height levelling with concealed dowel installation

Up to 17.5mm height compensation ✓ For indoors & outdoors ✓ Incl. slat dowels ✓

Our adjustment profile made of anodised aluminium is available in the colours silver, sahara, gold, bronze, matt stainless steel or polished stainless steel. The profiles with a total length of 900mm have a finely grooved surface which takes up about half of the 37mm wide visible side of the profile. The rear side has a profile rail that serves to accommodate the slat dowels, which, thanks to concealed installation, enables a continuous, closed look that is not spoilt by visible screws. The aluminium profiles are characterised by outstanding corrosion resistance and can be used without hesitation for both fixed and floating floor coverings indoors and outdoors thanks to the dowel fastening and enables height compensation from 17.5mm to 0mm.

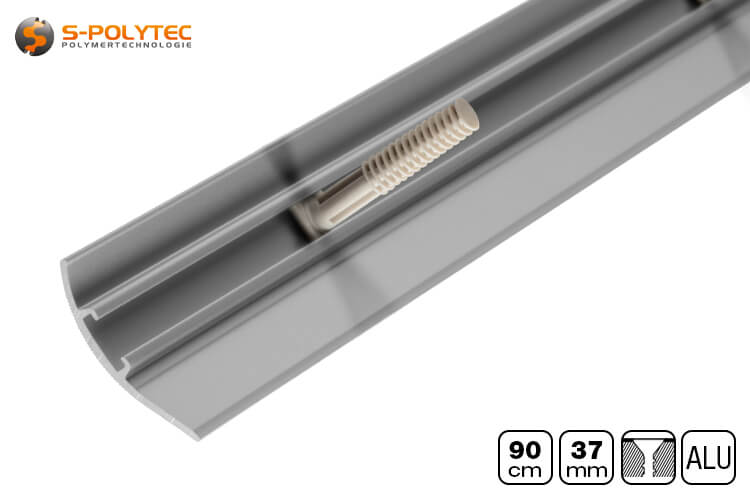

The slat dowels, which must be inserted into the profile rail for installation, are included in the scope of delivery and can be easily pressed out of the blister pack. This is shrink-wrapped together with the profile in a robust film that protects the anodised surfaces of the aluminium adjustment profiles from scratches and damage during transport.

NOTE: Aluminium is a light metal and can be cut to size very easily with a simple hacksaw. This also applies to the adjustment profiles with a profile thickness of 1.8mm.

Properties of the aluminium adjustment profile

Our 37mm adjustment profiles with a length of 90cm and a finely grooved surface are made of solid aluminium. This is a corrosion-resistant aluminium alloy, which is also anodised. The anodising process not only improves the weather resistance, but also achieves the attractive, even colouring of the surfaces, which are available in silver, sahara, gold, bronze, matt stainless steel or polished. The height of the profile when laid flat is around 6.5mm, but this is of little significance because as an adjustment profile for height levelling of up to 17.5mm, the actual height varies depending on the height difference between the two mounting surfaces. The profile rail on the down side not only increases the already very high flexural rigidity many times over, but is also used for concealed installation with the slat dowels, which are supplied in sufficient quantity with each profile. These dowels with a diameter of 6mm and a total length of 35mm are made entirely of plastic and can be inserted into the drilled holes without any screws and offer a certain degree of flexibility, so that the edges remain firmly in contact with the substrate at all times.

As a matching profile, this serves to equalise different heights between adjacent floor coverings, but can also be used as an optical transition for wall coverings, for example the currently very popular acoustic panels made of real wood. It does not necessarily have to be two different floor coverings. The levelling profiles can also be used if the thickness of a wall or floor covering needs to be evened out and visually appealing. Height levelling is possible for covering thicknesses up to a maximum of 17.5mm. With thicker floor coverings, however, it is not possible to ensure sufficient anchoring of the lamella dowels in the installation substrate.

The high-quality anodised coating is extremely resistant to the wear and tear that is typical of a floor profile. The finely grooved surface with a groove spacing of just under one millimetre provides a non-slip tread on the one hand, but at the same time also offers good grip so that suction robots can easily cope with the difference in height. When fitted as a skirting board on the wall or floor, the profile, which is used for a different purpose, not only creates a nice finish from the floor to the wall, but also serves as a cable duct at the same time.

Application and installation of the aluminium adjustment profiles with slat dowels

A drill with a 6mm drill bit is required to fit the aluminium adjustment profiles. A rubber mallet can also be quite helpful for carefully inserting the slat dowels into the drill holes. If the profiles are not used in their full length of 90cm and need to be shortened, a standard hacksaw with a saw blade for metal will suffice. The profile can also be cut to size with a handsaw without much effort. It is quicker and more precise to use a mitre saw, if available.

Before installation, you should check whether the profile needs to be cut to size. This is relatively simple for straight, simple cuts. However, if the profile is to be mitred at a certain angle, the profile must be aligned with the height compensation of the substrate. The profile requires one side to be positioned higher and one side to be positioned lower. When viewed from above, this is most easily recognised by the fine grooves, which are located closer to the side that ends on the higher floor covering.

TIP: The slat dowels are simply inserted into the rear profile rail and can be moved to the left or right at any time if required. The easiest way is to first insert all the dowels into the rail and distribute them along the length of the profile so that one dowel is positioned at the outer end of the adjustment profile and the others at similar distances from each other. If you now place the profile on the edge and position it where it is to be mounted, the necessary holes can simply be marked by transferring the positions of the dowels in the profile to the substrate.

After marking, the holes must be drilled. This requires a drill with a 6mm drill bit. This should be selected to suit the respective mounting surface. The mounting surface can be concrete, stone, screed, tiles as well as wood or wood-based materials, as the slat dowels also ensure a secure and firm hold in wooden beams or plywood. After drilling, briefly check that the positions of the holes match those of the slat dowels in the profile rail. Finally, the profile can be carefully inserted into the holes with the dowels and pressed into place so that the edges of the adaptation profile rest on the surfaces. Light taps with the palm of your hand should be more than sufficient. Alternatively, a rubber mallet can also be used, as this does not damage the surface of the aluminium profile, unlike a conventional hammer with a steel hammer track.

TIP: If the overall length is increased by one or more additional adjustment profiles, a dowel can be inserted halfway into the profile rails of the adjoining profiles. This creates a perfect transition.

Application examples of our aluminium adjustment profiles with height compensation

- The adjustment profiles with slat dowels can also be used outdoors

- Sealed, flawless surface thanks to concealed installation with flexible slat dowels

- The aluminium adjustment profiles are also suitable for floating floor coverings

- The special design of the profile allows height levelling from 17.5mm to 0mm

- As an alternative to skirting boards, cables can also be concealed behind the profile

Technical data of the aluminium matching profile

- Material: Aluminium

- Surface: Anodised

- Colour: silver, sahara, gold, bronze, polished stainless steel, matt

- Profile shape: Curved, finely grooved

- Standard length: 900mm

- Profile width: 37,0mm

- Profile height: Varies (depending on height compensation)

- Profile strength: Approx. 1,8mm

- Height equalisation: Max. 17,5mm

- Mounting type: Slat dowel (Mounting material included)

- Design: Concealed installation with rear profile rail

- Area of application: Indoors & outdoors

- UV-resistance: Excellent

- Weather resistance: Excellent

- Corrosion resistance: Excellent

- Additional Information

Additional Information

Product-ID UEP-P06 Delivery Time Dispatch within 2-3 working days Profile type Adjustment profile Material Aluminium anodised Area of applicationToepassingsgebied Inside & outside Color designation Varies Surface Fine grooved Property Perforated (incl. screws and dowels) Version Height adjustment 0mm - 17.5mm Length 900 mm Standard width 37mm - Reviews