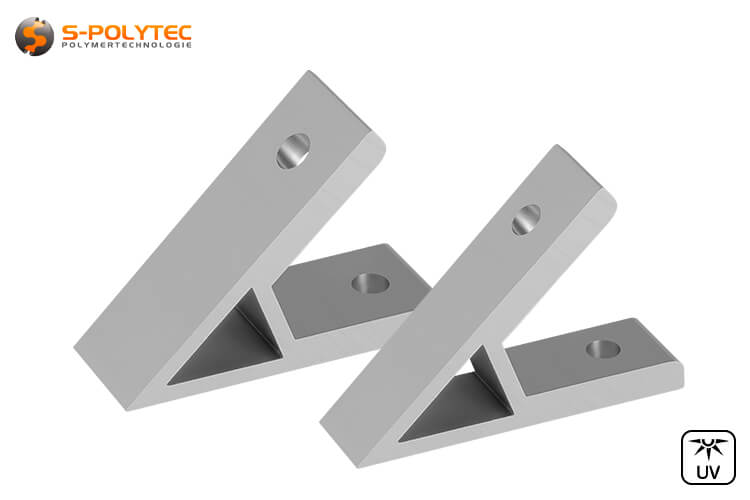

45° mounting bracket for construction profiles

The 45° mounting brackets made of corrosion-resistant aluminium are used to connect construction profiles with open grooves diagonally. The solid brackets are also very suitable for wall mounting or in furniture construction.

✓ Made of solid aluminium

✓ For diagonal connections

✓ Ideal for cap screws

✓ Simple profile connection

✓ Suitable for wall mounting

✓ For indoor and outdoor use

The 45° angle profile connectors for construction profiles are available in three different widths.

The item is in stock

Dispatch within 2-3 working days

- calculate the price

- from 10 Items €2.80/ pc. (Base Price €2.80/ pc.)

- from 20 Items €2.70/ pc. (Base Price €2.70/ pc.)

All prices include 19% VAT.

0,00 € / pc.

0,0000 kg / pc.

All prices include 19% VAT.

- Description

45° mounting bracket for construction profiles

Solid aluminium ✓ Also for wall mounting ✓ Versatile ✓

Our 45° mounting brackets made of solid aluminium in silver are available in three sizes, 20mm, 30mm and 40mm, and are intended for diagonal connections of construction profiles. However, the actual width is slightly smaller to ensure that it closes on the surface at rounded corners without protruding beyond the curve. The wide legs ensure a large contact area and also make it easy to mount on the profile. The high-quality aluminium alloy combines very high rigidity with very good corrosion resistance, making the profiles ideal for all outdoor installations.

The solid angle connectors made of extruded aluminium are not only compatible with all common construction profiles. They are also suitable for wall mounting in furniture construction, for the construction of metal structures made of aluminium or steel and much more. The large contact surfaces on both sides are reinforced by a web. This has a positive effect on the load capacity of the aluminium angle, so that the 45° angle does not decrease, even with increased load application.

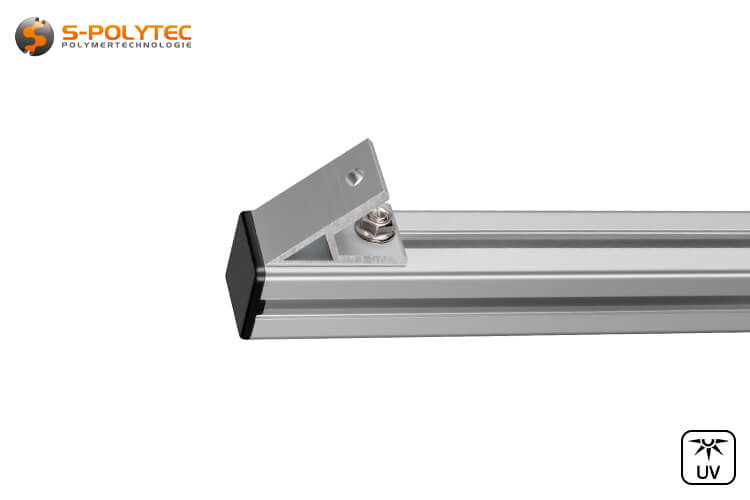

NOTE: To mount construction profiles at an angle of 45 degrees using the mounting brackets, two slot grooves with cylinder head screws or hammer head screws with grooves are required. The fasteners are available to match our construction profiles in different thread sizes for 6mm or 8mm slot widths at affordable graduated prices.

Properties of our 45° aluminium mounting bracket

Our angle connectors for profile connections at an angle of 45 degrees are available in three sizes for construction profiles with profile widths of 20mm, 30mm and 40mm. These are made of solid aluminium, which is characterised by its low weight, high stability and extremely good corrosion resistance. A round mounting hole on each side of the profile connector is used for secure and firm mounting on the profile. Because the mounting bracket has smooth mounting surfaces that are not affected by slot webs, the bracket can also be attached to any other smooth surface. This greatly increases the range of possible applications. From direct wall mounting, as an angle connector on steel and wooden structures, or for screwing to sloping roofs, to give just a few suggestions. Because aluminium is a rustproof light metal, the connector can also be used equally well indoors and for all conceivable applications in unprotected outdoor areas.

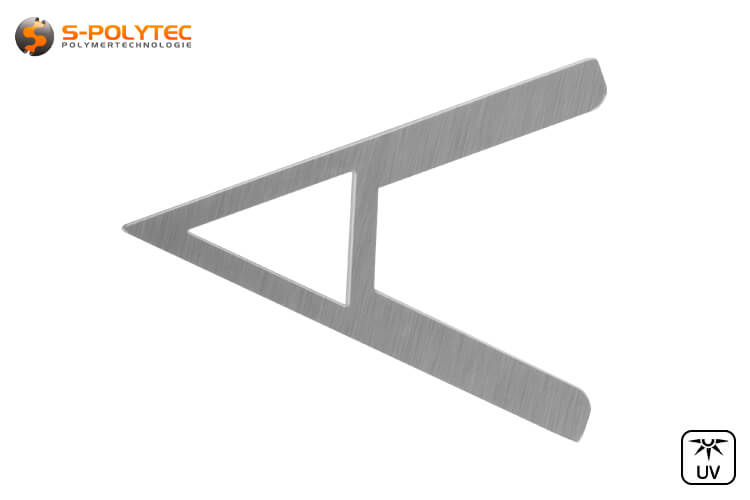

The angle connector has a material thickness of 3mm at the front acute angle, as well as for the centrally arranged intermediate reinforcement. The outer area, which also contains the mounting holes, is subject to the load acting on the construction and the connector and is twice as thick, at 6mm. This ensures that the angle, as well as the entire construction, is extremely stable.

The side view of the mounting bracket resembles the capital letter A. It is identical in height and length for all three versions. These are manufactured as a long profile using the static pressing process and then cut to the appropriate widths. This ensures we can offer the appropriate 45° angle mounting for each of our construction profiles. Even though the size of the angle is given as 20mm, 30mm or 40mm, the actual width is slightly smaller. This is because the size designation refers to the construction profile for which the mounting bracket is suitable and not to the dimensions of the aluminium bracket. The reason for the slightly reduced width is due to the rounded profile shape. This ensures that the profile is flush with the flat surface of an I-type system profile with rounded corners, which also includes our own construction profiles.

To mount the brackets, screws with a flat head are required. These can be cylinder head screws, dowel screws with a pan head or corresponding wood screws. We do not recommend using countersunk head screws to fasten the mounting brackets, because the conical screw head does not allow the screw to lie flat against the bracket, so that the load only acts on a very small part of the contact surface. This significantly reduces the load-bearing capacity of the fastening.

Specific data for the 45° mounting bracket

- 45° mounting bracket 20x20mm: Dimensions (WxDxH): approx. 18mm x 60mm x 42mm, Ø hole: 5.5mm, weight: 21g

- 45° mounting bracket 30x30mm: Dimensions (WxDxH): approx. 22mm x 60mm x 42mm, Ø hole: 6.5mm, weight: 32g

- 45° mounting bracket 40x40mm: Dimensions (WxDxH): approx. 32mm x 60mm x 42mm, Ø hole: 8.5mm, weight: 45g

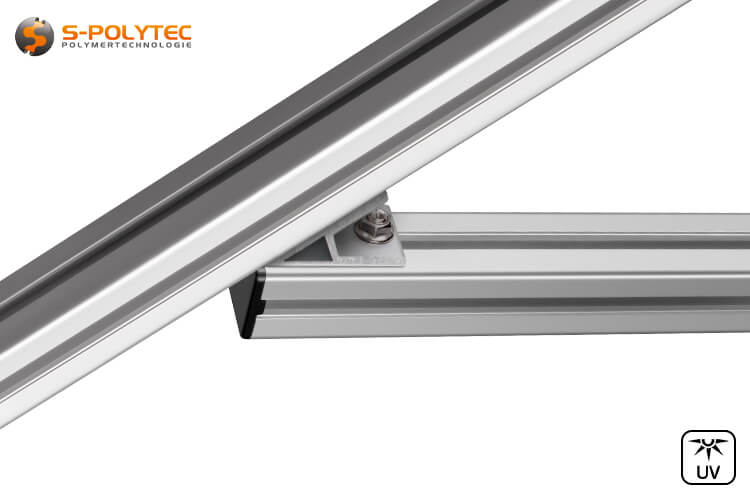

Installation and use of 45° angle connectors

When mounting on construction profiles, the 45° angle brackets are attached with T-slots and threaded screws with cylinder heads, or with hammer-head screws and flange nuts. The easiest way to do this is to prepare the mounting material for mounting by screwing the cylinder or hammer head screw through the mounting bracket a little into the slot nut or flange nut and only then inserting it into the slot of the profile and screwing it tight. When using a threaded screw, it is advisable to place a washer between the screw head and the bracket and to insert the screw from the inside of the connector. When using hammerhead bolts, the thread must be inserted from the outside. When using a flange nut, an additional washer is not required due to the increased contact area of the attached flange.

Both T-head screws and T-slots are fasteners that are especially suitable for construction profiles. Due to their special design, they can be inserted into the corresponding groove of a construction profile at any time and turn 90° when the screw is screwed in (or the slot is tightened), before they tilt within the groove. This ensures that the screw can be easily screwed in further without the hammer screw or T-slot turning. Therefore, when selecting the mounting material, it is important that it is matched to the size of the construction profile, especially with regard to groove depth and groove width. This information is always presented in a clear table in our fastening materials. Detailed information on the groove design of our construction profiles, on the other hand, can be found in the technical data at the end of the product description.

NOTE: Unlike our 90° mounting brackets, which we offer in a simple design or as a robust version with lateral reinforcement, the 45° aluminium brackets do not have slot bars on the mounting surface. They can twist if the fastening torque is insufficient. Therefore, care should be taken to ensure that the screws and sliding blocks are tightened sufficiently.

In combination with construction profiles, a 45° angle is ideal for reinforcing frames for machines with high mechanical loads through diagonal struts against torsion. Other possible uses include roof structures for greenhouses or canopies for shelters with a gabled roof, as well as the substructure of photovoltaic systems on flat roofs or balcony power plants that are to be mounted on a balcony or facade. The angle of inclination significantly increases the efficiency of the solar modules. Our aluminium angle bracket is primarily intended for construction with system profiles, but it can also be used in countless other areas where a 45° angle is required. When building a staircase or a stair railing, but also for mounting lightweight shelves, curtain rails or wall-mounted coat racks on sloping ceilings, the aluminium angle bracket can also be extremely helpful.

Examples of applications for 45-degree mounting brackets

- The 45° angle is ideal for diagonal bracing to reinforce machine constructions

- The brackets are perfectly suited for substructures of photovoltaic systems on flat roofs

- The angles can be used to build stairs and handrails made of aluminium, steel or solid wood

- Angle connectors are suitable for wall mounting, e.g. as a holder for curtain rails on sloping ceilings

- The aluminium angles are ideal for constructing garden houses and greenhouses with a gable roof

Technical data of the 45° mounting bracket

- Material: Aluminium

- Colour: Silver

- Angle: 45°

- Height: 42mm

- Width: 18mm up to 32mm

- Mounting holes: Round hole

- Ø hole drilling: 5.5mm up to 8.5mm

- Weight: 21g - 45g

- UV-resistance: Excellent

- Weather resistance: Excellent

- Corrosion resistance: Excellent

- Additional Information

Additional Information

Product-ID BFW-45-0000 Delivery Time Dispatch within 2-3 working days Property 45° mounting bracket Material Aluminium Color Silver - Reviews