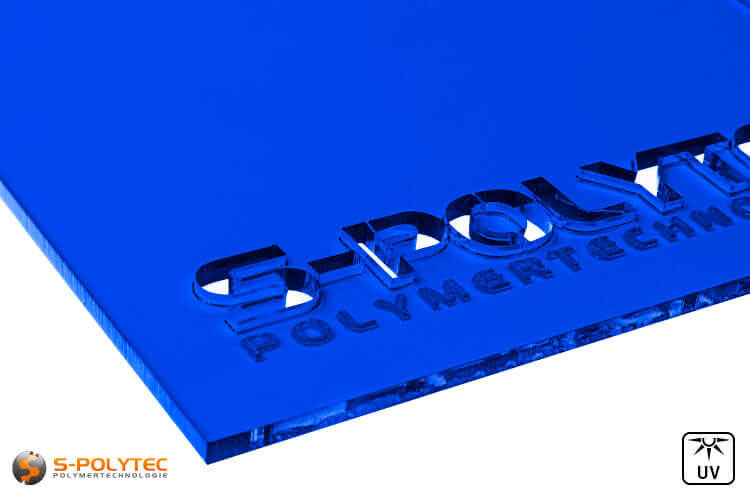

Acrylic glass blue laser-cut

Configure individual laser parts from weatherproof acrylic glass in blue at a reasonable price. Available in 3mm thickness up to 1500mm length and 980mm width. The sheets are transparent and have a greatly reduced light transmission of approx. 8% due to the dark blue colouring.

The item is in stock

Dispatch within 7 working days

- Forms

- Description

Configure acrylic glass blue in laser cut online

You can buy our acrylic sheets in blue up to a size of 1500mmx980mm conveniently online in individual laser cut at very favourable prices. The transparent sheets with an intense, dark blue colour are translucent, but due to the strong pigmentation they have a very reduced light transmission of only 8%. Our blue acrylic sheets in the laser cut are exclusively cast acrylic glass of extremely high quality. This is much more suitable for laser cutting and is characterised by a perfect cut edge that almost comes close to the high-quality, glossy surface of the sheets in terms of evenness and gloss level.

The acrylic glass sheets are completely dyed in the colour blue. This has the advantage that both the surfaces and the cut edges have the same strong blue colour. In addition, the sheets are solid acrylic glass made of solid core material and not hollow chamber or double web sheets.

NOTE: Our transparent acrylic sheets in dark blue have an easily removable protective film on both sides. However, this is not thermoformable and only serves to protect the surface.

Properties of the transparent acrylic glass in dark blue

Acrylic glass is a frequently used plastic that is transparent in its original form and can be dyed into almost any colour by adding pigments. Acrylic glass, or polymethyl methacrylate (PMMA for short), is offered by a wide variety of manufacturers in a wide variety of colours and designs. Many of them also have their own names for this plastic. The most common is probably the brand name Plexiglas®, which is very often used in common parlance for acrylic glass. It has very good UV and weather resistance and is one of the weatherproof plastics that can therefore also be used outdoors without having to worry about the beautiful, rich blue colour fading. With a temperature range of -40°C to +80°C, acrylic glass is frost-resistant and can also withstand high summer temperatures.

PMMA is a brittle material with a very high surface hardness. The advantage of this is that the surface does not scratch as quickly, but for the same reason acrylic glass is also less impact resistant and can therefore break more easily than less hard, brittle plastics. However, the impact resistance is still 8 to 10 times higher than conventional glass in a comparable format.

Our acrylic sheets in blue, like most coloured acrylic sheets, are mainly used for optical purposes in the advertising industry. For example, for wall coverings, for large-area advertising lettering in the form of individual letters that can be illuminated due to their translucency, or for product stands, flyer holders or to implement a corporate design for companies with corporate colours in deep blue. Blue acrylic glass is also used in gastronomy for effective lighting or counter designs or for the production of decorative articles, colourful upgrading of interior fittings and furniture or design objects and much more.

- Acrylic glass in blue is weatherproof, UV and weather-resistant and suitable for indoor and outdoor applications

- Blue acrylic glass has a hard surface and is therefore comparatively insensitive to scratches

- Blue acrylic glass has 8 to 10 times the impact strength of conventional glass

- Blue acrylic glass can be used at temperatures from -40°C to +80°C and is therefore frost-resistant

- Acrylic glass in blue has a greatly reduced light transmission of approx. 8% due to the dark colouring

- Acrylic glass in blue has a uniform, consistently high pigmentation in dark royal blue

- Acrylic glass in blue is classified as normally combustible according to DIN 4102 B2 and UL94 HB

Advantages of transparent acrylic glass in blue in laser-cut form

With our laser part configurator, circles, rings, ellipses, stars, triangles, squares, polygons and many other shapes can be created with just a few mouse clicks, which you can further customise according to your needs. Hole drilling is also very easy to create, so you can easily screw the blue acrylic blanks together without having to drill any holes yourself. Both the true-to-scale preview and the price calculation react to your entries in real time. So you can not only check the effects on the shape of your laser part, but also have your individual price in view at all times, which automatically deducts quantity discounts depending on the weight and quantity of your laser parts and thus always shows you the best possible price.

As soon as we receive your order, your laser parts are converted into a special file format and sent fully automatically to our laser equipment. All our employees have to do is place the dark blue acrylic sheet on the laser bed and start lasering. Automation not only allows us to process your order very quickly, resulting in short delivery times, but also enables us to offer a very competitive price for our laser cuts.

- Acrylic laser parts in the colour blue can be easily created via the online configurator

- Laser cutting ensures lower tolerances than is possible with conventional saw cutting

- The cut edge is not sharp-edged and saw-rough due to laser cutting, but smooth and shiny

- With our laser part configurator, almost any shape is possible instead of rectangular cuts

- Thanks to fully automated processes, fast delivery times and favourable prices are guaranteed

NOTE: Our laser cut dark blue acrylics are limited to a maximum size of 1500mmx980mm.

Post-processing of the acrylic laser cuts in blue

Our laser cuts are manufactured with high precision. Cutting the blue acrylic sheets to size should therefore not be necessary, but is nevertheless possible with simple tools such as those used in woodworking. Cut-outs can be made by milling or sawing. It is best to use a saw blade with medium toothing and choose a medium speed for rotation and feed. This prevents the sawdust from melting into the cut edge. A sharp drill bit for metal is suitable for drilling holes. During all processing steps, make sure that the acrylic sheet has no room to move and that it rests on a firm, level surface. Otherwise, there is a risk of chipping or, in the worst case, breakage in the sheet, rendering it unusable.

TIP: We also manufacture laser parts according to your drawing from the dark blue acrylic sheets with high precision at favourable prices on request.

For more flexibility in shaping, acrylic glass is often bent, folded or deep-drawn into a predefined shape. Due to the brittleness of PMMA, prior heating is necessary for this, because the sheets can break if they are subjected to too much stress due to deformation in a cold state. For thermoforming, the plastic sheet should be heated for a sufficiently long time in a temperature range between 150°C and 190°C. The duration of the heating is determined by the temperature of the sheet. The duration of heating depends on the exact temperature and the thickness of the material. When thermoforming, please note that the protective film cannot be thermoformed and must therefore be removed from the surfaces beforehand.

Acrylic glass has a special affinity for solvent-based adhesives and can therefore be bonded excellently with them. However, a fundamental distinction must be made with laser parts, because not all acrylic glass sheets in the laser cut are equally suitable for bonding with solvent adhesives. In the case of extruded acrylic glass, stresses are released during laser cutting that arise within the sheet as a result of the extrusion process. This can lead to stress cracks when in contact with solvents. However, our laser-cut acrylic sheets are cast material that has no internal stresses. Therefore, stress cracks are not to be feared. For bonding our laser parts made of blue acrylic glass, we recommend our colourless acrylic glass adhesive PMMAprofi from our own brand S-Polybond, which enables permanent and secure bonding in cold welding.

- Blue acrylic glass can be easily processed by sawing, milling or drilling

- Blue acrylic glass can be bonded very well with suitable adhesives

- Blue acrylic glass can be thermoformed at temperatures between 150°C and 190°C

- Blue acrylic glass can be screwed together, e.g. with stainless steel wall brackets

WARNING: Lasered acrylic glass in dark royal blue should not be cleaned with alcohol to avoid stress cracks.

Letters, logos and engravings on request

With our laser cuts, we are not limited to laser parts from the laser part configurator, but are also able to laser almost any shape for you from our dark blue acrylic glass sheets. From laser parts exactly according to your design drawing, to letters, numbers and lettering in any typography, to laser engravings for effectively illuminated company signs or decorative objects, almost no wish remains unfulfilled with our laser systems.

- Acrylic glass in blue as letters, numbers, complete lettering or logos in laser cut

- Laser cuttings from dark blue acrylic glass exactly according to your conception in highest precision

- Single perforated holes, perforated plates or cut-outs in any shape from blue acrylic glass

- Laser engraving on the back (mirror-inverted) or on the front

- Laser parts from prototype to series production with high dimensional accuracy in blue acrylic

- and much more

Further possibilities of our CO2 laser system on request:

You have specific ideas regarding laser cuts and our configurator is reaching its limits? Just give us a call or send us an email with your requirements. We will do our best to implement all your wishes.

Plexiglas® is a registered brand name of Röhm GmbH.

- Additional Information

Additional Information

Product-ID 51073L Thickness 3mm Standart Length 1520 Standard width 1010 Delivery Time Dispatch within 7 working days Plastic Acrylglas Material PMMA UV resistance UV resistant Color Blue Color accuracy Color similar to RAL color system - Reviews

- Attachments