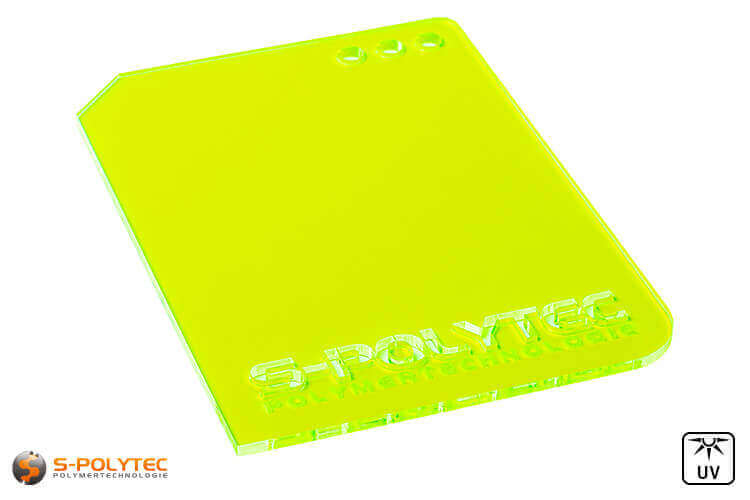

Acrylic glass green fluorescent laser-cut

Configure your individual laser parts made of acrylic glass in bright fluorescent green inexpensively online with our laser part configurator. The neon-like sheets are configurable in 3mm thickness up to 1500mm length and 980mm width. The green sheets are transparent and have a very high light transmission of approx. 87% despite the pigmentation. The cut edges of the fluorescent acrylic sheets have a self-luminous effect.

The item is in stock

Dispatch within 7 working days

- Forms

- Description

Acrylic glass green fluorescent laser cut

Our acrylic sheets in fluorescent green can be configured online as individual laser cuts up to a format of 1500mmx980mm. The sheets are transparent and have a very high light transmission of approx. 87% despite the strong colouring. This is due to the bright colour of the bright green acrylic sheets, which appear more neon yellow than green depending on the light intensity and ambient brightness. Due to the strong pigmentation with special fluorescent pigments, the edges of the green sheets appear as if they were self-luminous. This effect is particularly effective with the light green, neon-like panels. Laser cutting preserves this effect. While cutting by sawing or milling makes the cut edge dull, cutting with a CO2 laser makes the edges look smooth and polished, with a gloss level comparable to the surface of the panels. The excellent quality of the cut edge is also due to the acrylic glass used. In order to guarantee the best possible result of your laser parts, we only use cast acrylic glass instead of extruded sheet material. Due to the special manufacturing process of the plastic sheets, perfect cuts are possible in terms of dimensional accuracy and quality of the cutting edge.

The coloured acrylic sheets in fluorescent green are pigmented bright green and coloured throughout the entire thickness. The PMMA sheets in the laser cut are exclusively solid sheets and not hollow chamber or double web sheets.

NOTE: Our coloured acrylic sheets in fluorescent green are covered on both sides with a protective film to protect the surfaces, which can be easily removed once processing is complete.

Properties of the acrylic glass in green fluorescent

Our acrylic glass sheets with fluorescence can be configured in different colours as laser cuts at favourable prices. Fluorescent stands for a very special effect that is created by the addition of special colour pigments. These sheets appear as if they glow at the cut edges. This effect, which is particularly visible in indirect lighting or subdued light, is used especially for eye-catching, colourful decoration or in the advertising industry.

The acrylic glass sheets with bright green edges are conventional acrylic glass that has the same positive properties as the well-known transparent sheets. These sheets are often referred to as Plexiglas. However, Plexiglas® is merely a registered brand name for acrylic glass from Röhm GmbH. There are many other manufacturers with even more brand names under which acrylic glass is available on the market. However, the correct chemical designation is the same for all of them and is PolyMethylMethAcrylate, which is also where the common abbreviation PMMA comes from.

Particularly noteworthy are the very good weatherproof properties of acrylic glass. This plastic is naturally UV and weather resistant, which allows it to be used indoors and outdoors. The danger of ultraviolet radiation causing the bright green colour to fade or the sheet to become brittle over time is eliminated by the UV resistance. Even sub-zero winter or summer temperatures have no effect on the usability of the acrylic glass blanks, because the temperature range in which the sheets can be used extends from a low of -40°C to temperatures as high as +80°C.

The PMMA sheets with luminous edges are most frequently used for the production of garden decorations. The neon-like acrylic sheets in green are no exception. The transparent sheets are also very popular as colourful window decorations and are sometimes combined in different colours. The high light transmission of the green sheets also allows them to be used as whiteboards with backlighting. With matching markers, for example in white, an otherwise dull white memo board can be skilfully highlighted. Thanks to the bright colour with a high eye-catching factor, the fluorescent boards are used for highly effective advertising. For example, to progressively advertise new care products or to make company buildings eye-catching with illuminated advertising.

- Acrylic glass green fluorescent is weatherproof, UV and weather resistant and can be used indoors and outdoors

- Acrylic glass green fluorescent is comparatively insensitive to scratching due to its high surface hardness

- Acrylic glass green fluorescent has an 8 to 10 times higher impact strength compared to conventional glass

- Acrylic glass green fluorescent is frost-resistant and can be used permanently at temperatures from -40°C to +80°C

- Acrylic glass green fluorescent has a high light transmission of approx. 87% despite the high pigmentation

- Acrylic green fluorescent captivates a bright neon colour in light green with fluorescent cut edges

- Acrylic glass green fluorescent is considered normally combustible (according to DIN 4102 B2, UL94 HB)

Advantages of acrylic glass green fluorescent in laser cutting

Create your individual laser parts made of acrylic glass in fluorescent green conveniently online with our specially developed laser part configurator and benefit from particularly favourable prices for high-quality laser cuts in excellent quality. For the configuration of your laser parts, you can choose from the most common basic shapes, such as rectangles, circles or rings to any triangles, stars or polygons. These basic shapes serve as the basis for your individual customisation and, if required, can also be provided with hole drillings with just a few mouse clicks. To see the effects of your input, you can use our real-time preview with a true-to-scale image of your laser part. Thanks to our weight-dependent price calculation, which also calculates in real time, you will always receive the best possible price for your blanks. Discounts for larger formats or higher quantities are automatically deducted.

The laser cuts you configure from our bright green acrylic glass, are automatically created in a file format that our modern laser systems can process. These are transmitted directly to the laser. Thanks to non-contact cutting, not only are very low tolerances guaranteed, but also evenly smooth and polished cut edges, which would not be possible with our panel saws. For this reason, we offer our neon-green acrylic sheets with fluorescent effect exclusively in laser cutting. Sawing would make the cut edges rough and cloudy, which would result in a high loss of the luminous effect.

- Fluorescent acrylic in laser cutting is characterised by a luminous effect at the edges

- Laser parts can be cut with very low manufacturing tolerances thanks to non-contact cutting

- Laser cutting of green acrylic makes the cut edges polished, smooth and shiny instead of saw-rough

- Laser cutting offers maximum flexibility for shaping as opposed to traditional saw cuts

- Using our configurator, customised laser cuts of green acrylic are easy to create

NOTE: The size for our green acrylic laser cuts is technically limited to a maximum of 1500mmx980mm.

Post-processing of laser cuts from acrylic glass

Acrylic glass sheets can be processed very easily in order to cut them to the desired size or to prepare them for assembly. Although cutting should not be necessary for our fluorescent green acrylic laser parts, it can be done with any tool that is also used for woodworking. For this purpose, you can choose between sawing, milling or grinding. It is important that both the speed and the feed rate are set in the medium range. This prevents the sawdust from melting into the cutting edge due to the heat generated. In addition, it should be ensured that the boards rest on a firm, level surface and are fixed in place, so that so-called fluttering of the boards is prevented. This can lead to chipping or even breakage of the entire acrylic sheet. The same applies to drilling. For drilling holes, it is best to use a sharp drill made of HSS steel, which is also used for drilling metal, in order to obtain sharp-edged, clean drill holes.

Acrylic glass is a plastic that can generally be bonded very well. Laser cutting releases a certain amount of tension on the surfaces of the cut edges, which is why solvent-based adhesives should not be used, as this leads to tension cracks. This is another reason why only cast acrylic sheets are used for our laser cuts, as these do not have any tension and can therefore also be bonded with solvent-based adhesives such as our S-Polybond PMMAprofi without stress cracks occurring.

A temperature between 150°C and 190°C is required for deep-drawing parts from the neon-like acrylic sheets. How long the sheets have to be heated for thermoforming depends on the thickness and the selected temperature. Thermoforming itself is a very common method of producing finished acrylic parts and is quite easy to implement as a thermoplastic. The self-luminous effect of the fluorescent acrylic sheets is not only very effective on the cut edges of deep-drawn parts, but also on curved surfaces or bends.

Acrylic glass is also excellent for bending or folding. However, it is also necessary to heat the sheets beforehand, otherwise they may break. After cooling, the acrylic plastic sheets remain in the desired shape.

- Fluorescent acrylic glass green can be easily processed by milling, sawing or drilling

- Fluorescent acrylic glass green can be bonded very well with solvent-free adhesives

- Fluorescent acrylic green can be deep-drawn at temperatures between 150°C and 190°C

- Fluorescent acrylic glass green can be screwed together, e.g. with stainless steel wall brackets

WARNING: Laser cuts made of acrylic glass cannot be cleaned with alcohol, as this can cause stress cracks on the laser edges.

Laser engravings and complex laser cuts on request

Would you like laser cuts that are not possible with our configurator? We also manufacture laser parts exactly according to your design drawing up to a format of 1500mmx980m from our green acrylic sheets with fluorescent cutting edge. Almost any shape is possible. Letters, lettering or company logos, even with individual laser engraving if desired, are also possible with our modern CO2 laser systems. Our friendly team will be happy to answer any questions you may have and to provide you with a concrete quotation by telephone or e-mail.

- Letters and complete lettering or logos in laser cut acrylic glass green fluorescent

- Laser cuts exactly according to your design drawing as vector file with high dimensional accuracy

- Single perforated holes, perforated plates or any cut-outs made of acrylic glass green fluorescent

- Laser engravings on back or front with luminous effect in green fluorescent acrylic

- Laser parts in series production also in high quantities made of acrylic glass green fluorescent

- and much more

Further possibilities of our CO2 laser system on request:

Plexiglas® is a registered brand name of Röhm GmbH.

- Additional Information

Additional Information

Product-ID 51960L Thickness 3mm Standart Length 1520 Standard width 1010 Delivery Time Dispatch within 7 working days Plastic Acrylglas Material PMMA UV resistance UV resistant Color Green Color accuracy Color similar to RAL color system Color designation Green fluorescent - Reviews

- Attachments