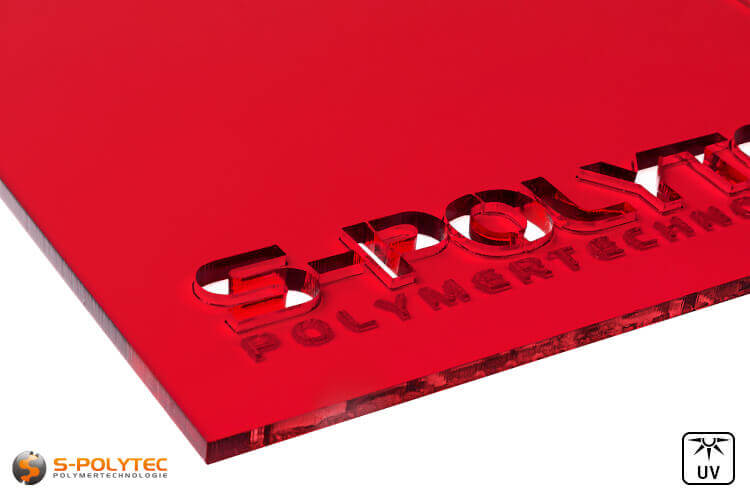

Acrylic glass red laser-cut

Configure individual laser parts made of weatherproof acrylic glass in red at a reasonable price. Available in 3mm thickness up to 1500mm length and 980mm width. The sheets are transparent and have a reduced light transmission of approx. 13% due to the red colouring.

The item is in stock

Dispatch within 7 working days

- Forms

- Description

Acrylic glass red in perfect laser cut

Our acrylic sheets in red can be configured up to a format of 1500mmx980mm as individual laser cuts online at favourable prices. The transparent sheets have a high pigmentation. The light transmission of the red acrylic glass is significantly reduced and is approx. 13%. This is due to the strong colouring. Due to the cutting with a CO2 laser, the cut edges are evenly smooth and have a comparable gloss level to the smooth, glossy surfaces. The perfect laser edges are also due to the use of the material. In contrast to extruded acrylic glass, our laser-cut acrylic glass sheets are cast material. Cast acrylic can be laser-cut much more cleanly than extruded acrylic.

Our transparent acrylic sheets in red are completely dyed through, so that the surfaces and cut edges have the same deep red colour. Our laser-cut acrylic sheets are exclusively solid sheets and not twin-wall sheets or double-wall sheets.

NOTE: Our coloured acrylic sheets in red are equipped with a protective film on both sides, which can be easily removed once processing is complete.

Properties of acrylic glass in red transparent

In its original form, acrylic glass is a transparent plastic that is characterised by its high surface hardness. As a result, the sheets are considered scratch-resistant compared to most other plastics. It is up to 10 times more impact-resistant than conventional glass and weighs only about half as much. Acrylic glass, which is also called Plexiglas in common parlance, is therefore also very often used as a glass substitute. In addition to the lower weight, the weatherproof properties of acrylic glass are further aspects for its use as a plastic pane. The sheets are UV and weather resistant and can be used both indoors and outdoors.

The red acrylic glass sheets are also transparent plastic sheets, but they are given a strong red colour by the addition of special colour pigments. The sheets are also transparent and have a reduced light transmission. Due to the UV resistance, the colours do not fade even in long-lasting direct sunlight. Acrylic glass also does not become brittle, as is the case with most plastics that are not UV-resistant. Acrylic glass, whose chemical name is polymethyl methacrylate (PMMA for short), is frost-resistant down to -40°C and can be used permanently up to a maximum temperature of approx. +80°C.

PMMA is not only used as plastic glazing, however. Red acrylic sheets in particular are very often used for coloured light. This is the case, for example, with rear lights in the automotive industry. Coloured acrylic glass is also used as shelves with indirect lighting. Other areas of application for the colourful sheets are in consumer electronics, as transparent housings, as wall panelling and room dividers or even as decorative elements. The translucent sheets are also frequently found as lettering on company buildings. Mostly as lettering in the form of individual letters cut by laser, which ensure a high attention factor with lighting on the back.

- Acrylic glass in red is weatherproof, UV and weather-resistant and can be used indoors and outdoors

- Red acrylic glass is relatively resistant to scratching due to its high surface hardness

- Red acrylic glass has 8 to 10 times the impact strength of conventional glass

- Acrylic glass in red is frost-resistant and can be used permanently at temperatures from -40°C to +80°C

- Acrylic glass in red has a significantly reduced light transmission of approx. 13% due to the colouring

- Acrylic glass in red impresses with a strong red colour with uniform pigmentation

- Acrylic glass in red is classified as normally combustible (according to DIN 4102 B2, UL94 HB)

Advantages of laser-cut transparent acrylic in red

Ordering acrylic glass in laser cut has never been so easy. With our laser part configurator, you not only create your individual laser parts very conveniently online, but also benefit from an unbeatable price. All the basic shapes in our configurator are available for our red acrylic sheets. Simply choose between the different shapes and adjust them as required until you have created your desired laser parts. Optionally, hole drillings are also added in no time at all. Thanks to preview and price calculation in real time, you always have your configuration in view and can check the effects of your entries.

Thanks to fully automated processes, you benefit from very favourable prices, with quantity discounts already deducted depending on the weight and number of your laser parts. As soon as your order is completed, a file is automatically generated that can be processed by the laser. All our production staff have to do is load it and place the red acrylic sheets on the laser bed to complete the production. This is not only efficient, but is also extremely fast, so that in addition to the favourable prices, very fast delivery times can also be met.

- Laser parts made of red acrylic in individual shapes are created with just a few mouse clicks

- Laser cutting ensures lower tolerances compared to conventional saw cuts

- With laser cutting, the cut edge is evenly smooth and polished instead of rough and cloudy

- Instead of only rectangular saw cuts, almost all shapes can be configured by laser cutting

- Thanks to fully automated processes, fast delivery times and favourable prices are guaranteed

NOTE: The size for our red acrylic laser cuts is technically limited to a maximum of 1500mmx980mm.

Post-processing of laser cuts from red acrylic glass

The post-processing of laser parts made of acrylic glass can be done in different ways. Thanks to the high precision of the cuts, further cutting is generally not necessary. However, in the event that cut-outs, holes or shapes (for example letters and logos) are to be made that cannot be implemented with our configurator, this can be done without further ado by sawing, milling or laser cutting. For sawing or milling, we recommend the use of woodworking tools. For drilling, you will achieve the best results with a drill for metal. The boards should always rest firmly on a flat surface. This prevents the risk of splintering or chipping when drilling or sawing.

TIP: We also manufacture individual laser parts according to your drawing from our red acrylic glass sheets at fair prices on request.

Acrylic glass is a thermoplastic. This means that the solid sheets can be shaped into almost any three-dimensional form by heating, which is retained after cooling. Temperatures between 150°C and 190°C are required for the so-called thermoforming. The duration of heating depends on the thickness of the sheets and the exact temperature. Thermoforming of red PMMA sheets is a widespread practice, for example for the production of vehicle rear lights or lampshades. Sufficient heating in terms of duration and temperature is also required for bending or folding. Otherwise, there is a risk of the brittle sheets breaking.

Bonding acrylic glass is very easy, for example, to produce enclosures from the transparent sheets in red. However, laser cutting of extruded acrylic sheet releases stresses, which is why solvent-based adhesives are not suitable. The solvent dissolves the surfaces and this can lead to unsightly stress cracks on the lasered cut edges. However, since we only use cast acrylic glass sheets for our laser cuts, there is no danger of this, so we recommend our cold welding adhesive PMMAprofi for bonding our laser parts, which was specially developed for bonding acrylic glass.

- Red acrylic glass can be easily processed by milling, sawing or drilling

- Red acrylic can be bonded very well with solvent-free adhesives

- Red acrylic can be deep-drawn at temperatures between 150°C and 190°C

- Red acrylic glass can be screwed together, e.g. with stainless steel wall brackets

WARNING: Lasered acrylic glass blanks in red must not be cleaned with alcohol, as this can lead to stress cracks on the laser edges.

On request also laser engravings and complex laser cuts

With our laser part configurator, a lot is already possible. However, much more is possible with our CO2 laser systems. From more complex shapes, letters, numbers and logos to complete lettering in any font or company logos, we can produce blanks in almost any shape with the highest precision. Engraving our red acrylic glass plates is also no problem for us.

- Letters and complete lettering or logos laser-cut from acrylic glass in red

- Precise laser cuts exactly according to your design drawing in any shape

- Single hole drillings, perforated plates or cut-outs from our red acrylic glass plates

- Laser engravings optionally on the back (mirror-inverted) or on the front

- Series production of laser cuttings in high quantities from red acrylic glass

- and much more

Further possibilities of our CO2 laser system on request:

Simply send us an email with your requirements and we will get back to you as soon as possible.

Plexiglas® is a registered brand name of Röhm GmbH.

- Additional Information

Additional Information

Product-ID 51040L Thickness 3mm Standart Length 1520 Standard width 1010 Delivery Time Dispatch within 7 working days Plastic Acrylglas Material PMMA UV resistance UV resistant Color Red Color accuracy Color similar to RAL color system - Reviews

- Attachments