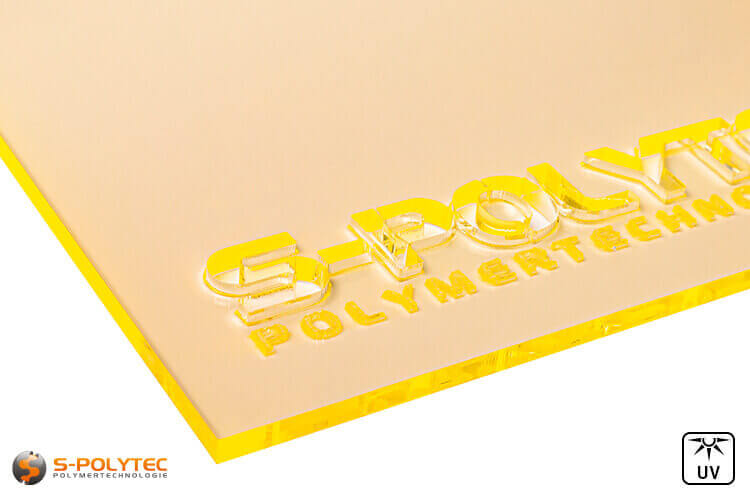

Acrylic glass yellow fluorescent laser-cut

Configure your individual laser parts made of acrylic glass in fluorescent yellow online and benefit from the flexible, diverse configuration options. Available in 3mm thickness up to 1500mm length and 980mm width. The sheets are transparent yellow and have a reduced light transmission of approx. 72% due to the colouring. The edges have a fluorescent, self-luminous effect.

The item is in stock

Dispatch within 7 working days

- Forms

- Description

Acrylic glass yellow fluorescent in laser cutting

Our acrylic sheets in fluorescent yellow are available up to a maximum format of 1500mmx980mm in laser cut. The sheets are transparent and have a strong yellow colour, which is approximately between RAL 1023 (Traffic yellow, applies to the surface on a white background) and RAL 2007 (Luminous bright orange, applies to the fluorescent edge). Due to the colouring, the acrylic glass sheets have a slightly reduced light transmission of approx. 72%. The special feature of fluorescent acrylic sheets is the optical effect of the cut edges. This is particularly effective with smooth, polished laser cuts and is noticeable through a self-luminous effect. In order to guarantee you laser cuts of perfect quality, we only use acrylic glass sheets made of cast material for our bright yellow acrylic glass and no extruded plastic sheets. The special manufacturing process allows for a much better laser edge, whose evenness and gloss level is almost comparable to the sheet surface. This has an even greater effect on the luminous effect, especially with the fluorescent sheets.

The coloured acrylic sheets in fluorescent yellow are completely dyed through and have an even pigmentation. For our laser cuts, we only use solid acrylic sheets and no double-wall sheets or twin-wall sheets.

NOTE: Our yellow fluorescent acrylic glass sheets are equipped with a protective film on both sides to protect the surfaces. However, this can be easily removed after processing.

Properties of the acrylic glass in fluorescent yellow

Colourful acrylic sheets in fluorescent designs are available in our online shop in various colours as laser cuts and can be configured conveniently and inexpensively online. The fluorescence of the yellow acrylic sheets gives the appearance of the cut edges glowing or being illuminated by a light source. This self-luminous effect is best seen in indirect lighting or in subdued light, e.g. at dusk, and is made possible by the addition of special colour pigments. The surfaces of the smooth, transparent panels, however, remain unaffected by this luminous effect.

The areas of application of the special sheets range from decorative items in the garden, to advertising lighting, to advertising displays for an eye-catching presentation of new products or print media. The glossy surfaces of the yellow acrylic sheets are transparent and smooth with a reduced light transmission of about 72%. The slight reduction in light transmission is due to the colour pigments that give the sheets their rich yellow colour.

Acrylic glass is a weatherproof plastic with the chemical name polymethyl methacrylate, also abbreviated to PMMA. The most common name is probably Plexiglas®, which is, however, a registered brand name for acrylic glass sheets from Röhm GmbH. However, acrylic glass is also used under many other brand names by various manufacturers.

Acrylic glass is a UV-resistant and weatherproof plastic and as such can also be used for outdoor applications. Due to the UV resistance, the strong yellow colour does not fade and there is no risk of the transparent sheets becoming brittle. Due to the generous temperature range from -40°C to +80°C, the PMMA sheets can also be used permanently outdoors. Neither deep frost nor strong sunlight restrict this plastic when used outdoors. This makes colourful plastic glazing, decoration or lighting possible, e.g. for company buildings, which achieve an eye-catching effect due to the fluorescence, attracting the eye almost magnetically.

- Acrylic glass yellow fluorescent is weatherproof, UV and weather resistant and suitable for outdoor use

- Acrylic glass yellow fluorescent has a high surface hardness and is therefore relatively scratch-resistant

- Acrylic glass yellow fluorescent has an impact strength 8 to 10 times higher than glass

- Acrylic glass yellow fluorescent can be used at temperatures from -40°C to +80°C

- Acrylic glass yellow fluorescent has a high light transmission of approx. 72% despite the colouring

- Acrylic glass yellow fluorescent impresses with a rich yellow colour with radiant cut edges

- Acrylic glass yellow fluorescent is classified as normally combustible (according to DIN 4102 B2, UL94 HB)

Advantages of acrylic glass yellow fluorescent in laser cutting

Configure your laser cuts from our fluorescent acrylic sheets in yellow inexpensively online. With our specially developed laser part configurator, individual shapes based on the most common basic shapes are created quickly and easily and can be provided with hole drillings if required. Thanks to the true-to-scale real-time preview, you always retain full control over your desired configuration and our price calculation always provides you with the best possible price for your laser cuts and takes quantity discounts into account fully automatically depending on the weight.

Our CO2 lasers are state of the art. This allows very low tolerances for our laser cuts. In addition, we only use cast acrylic glass sheets of the highest quality for our laser parts to ensure the best possible appearance of the cut edge. Especially with the fluorescent sheets, this is noticeable through an even better luminous effect. Through laser cutting, the cut edges are evenly smooth with a polished surface. If we were to saw-cut the sheets, the edges would be dull and rough, which would result in the loss of a large part of the fluorescence. That is why we offer these special sheets exclusively in laser cutting.

- Laser-cut fluorescent acrylic has a smooth, polished edge with a luminous effect

- Laser parts can be produced with a very high dimensional accuracy thanks to non-contact cutting

- Laser cutting of yellow acrylic means that the blanks do not have sharp edges or burrs

- Laser cutting offers maximum flexibility for any shape, for example for product displays

- With our configurator, laser cuts of yellow acrylic glass can be conveniently configured online

NOTE: The maximum size of our acrylic laser parts is limited to 1500mmx980mm. The maximum size of our acrylic laser parts is limited to 1500mmx980mm.

Post-processing of laser cuts from acrylic glass

Finishing acrylic is very easy to do. Although cutting to size should not be necessary due to the simple configuration for laser cuts, it is still possible. All cutting methods such as milling, sawing, grinding or drilling are available for this purpose. For cutting, it is best to use woodworking tools or metal drills for drilling holes. Make sure that the speed is in the medium range to prevent the chip from fusing with the cut edges.

Bending or folding is also possible with acrylic glass. It should be noted, however, that the sheets must be heated for this, as acrylic glass can otherwise break.

If you want to glue the laser cut yellow acrylic sheets, we recommend our special acrylic glass adhesive PMMAprofi. In principle, stresses are released when acrylic glass is laser cut, but since our acrylic glass sheets in fluorescent yellow are cast and not extruded sheets, no stresses are released during laser cutting either. This means that no stress cracks occur when solvents are used, which can certainly be the case with extruded PMMA.

Acrylic glass is one of the thermoplastics that can be excellently deformed by the action of heat. Especially with fluorescent acrylic sheets, stretching creates an exciting, visually exciting effect. A temperature of between 150°C and 190°C is required for deep-drawing. The heating time depends on the specific temperature and the thickness of the acrylic sheet. However, the protective film must be removed on both sides beforehand, as this is not suitable for deep-drawing.

- Fluorescent acrylic yellow can be drilled, milled or sawn without any problems

- Fluorescent acrylic glass yellow can be bonded with suitable adhesives

- Fluorescent acrylic yellow can be thermoformed at temperatures between 150°C and 190°C

- Fluorescent acrylic glass yellow can be screwed, e.g. with stainless steel wall brackets

WARNING:Laser cuts made of acrylic glass must not be cleaned with alcohol. This can lead to stress cracks on the laser edges.

More complex shapes and laser engravings on request

With our laser part configurator, we offer you a wide range of options for adapting laser cuts to your own needs online. In addition, we are also able to produce your individual laser cuts exactly according to your design drawing. From individual letters from the bright yellow acrylic glass to entire lettering. We can also produce series of complete kits for product stands, company lettering or displays with our laser systems on request. Laser engravings on the smooth surfaces create a special effect, especially with the fluorescent acrylic glass panels. Our friendly team will be happy to answer any questions you may have and to provide you with a concrete quotation by telephone or e-mail.

- Letters and lettering in laser cut acrylic glass yellow fluorescent

- Any shapes according to your drawing in vector format in exact laser cutting

- Individual perforated plates and any cut-outs in acrylic glass yellow fluorescent

- Laser engravings with luminous effect made of acrylic glass yellow fluorescent

- Series production of laser cuttings from acrylic glass yellow fluorescent

- and much more

Further possibilities of our CO2 laser system on request:

Plexiglas® is a registered brand name of Röhm GmbH.

- Additional Information

Additional Information

Product-ID 51950L Thickness 3mm Standart Length 1520 Standard width 1010 Delivery Time Dispatch within 7 working days Plastic Acrylglas Material PMMA UV resistance UV resistant Color Yellow Color accuracy Color similar to RAL color system Color designation Yellow fluorescent - Reviews

- Attachments