Facade rivets black (RAL 9005)

Aluminium facade rivets in black (RAL 9005, deep black) with facade approval for HPL panels and aluminium composite panels from various manufacturers for the construction of facade cladding on aluminium substructures at particularly favourable graduated prices.

✓ Corrosion-resistant

✓ For interior and exterior use

✓ Scratch-resistant head coating

✓ Secure hold

✓ Steel rivet mandrel

The black facade rivets can be ordered with 14mm, 16mm or 18mm hollow rivet length already from one rivet.

The item is in stock

Dispatch within 2-3 working days

- calculate the price

- from 20 Items €0.88/ pc. (Base Price €0.88/ pc.)

- from 50 Items €0.81/ pc. (Base Price €0.81/ pc.)

- from 100 Items €0.68/ pc. (Base Price €0.68/ pc.)

- from 250 Items €0.54/ pc. (Base Price €0.54/ pc.)

- from 500 Items €0.40/ pc. (Base Price €0.40/ pc.)

All prices include 19% VAT.

0,00 € / pc.

0,0000 kg / pc.

All prices include 19% VAT.

- Description

Aluminium facade rivets in jet black (RAL 9005)

From 1 piece ✓ Attractive graduated prices ✓ UV- and weatherproof ✓

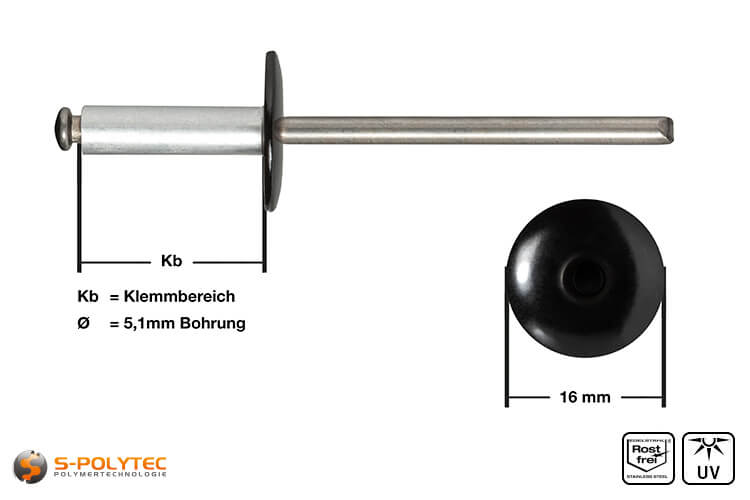

Our black facade rivets correspond to the colour RAL9005 (jet black) and have a round, flat rivet head with a large head diameter of 16mm. They are ideally suited for mounting HPL panels or aluminium composite panels in black, which are to be mounted on an aluminium substructure. The blind rivets produced in Germany are made of aluminium with a stainless steel mandrel. However, when the rivet is placed correctly with a suitable blind riveting tool, the mandrel tears at the predetermined breaking point so that only the crushed blind rivet sleeve with the firmly connected rivet head remains as fastening.

No matter how many facade rivets you need, in our online shop you can order exactly the quantity you want instead of being forced to buy complete boxes of 100 rivets and, depending on the order quantity, you can still benefit from our particularly favourable graduated prices.

-

Scope of delivery:

- 1 x Facade rivet with head coating in black (RAL 9005)

TIP: A riveting tool is required to fasten the black facade rivets.

Characteristics of our facade rivets in black

Our black aluminium facade rivets have a scratch-resistant head coating in RAL 9005 (deep black) and are matched in colour and gloss level to our black HPL panels, but are also excellently suited for mounting our black aluminium composite panels and many more of our plastic panels in black. As a large-head blind rivet with a head diameter of 16mm, the facade rivets are sufficiently large to completely cover even large sliding point drill holes with a diameter of 8mm or even 10mm. This is a very big advantage especially for facade claddings and balcony borders with cladding panels with high thermal expansion. Furthermore, the rivets have a facade approval in connection with HPL facade panels of various well-known manufacturers.

Both the aluminium alloy and the lacquering of the rivet head are weatherproof and UV-resistant, so that the rivets can be used outdoors without hesitation. Aluminium does not rust and there is no risk of the deep, black colour fading, even with strong, continuous UV radiation.

WARNING: The aluminium rivets are only suitable for aluminium substructures and should therefore not be used for rivet joints of balcony claddings on steel railings as this can lead to contact corrosion.

Technical data of black facade rivets

- Colour: RAL9005 (Jet Black)

- Hollow rivet diameter: 5,0mm

- Hollow rivet length: 14mm, 16mm or 18mm

- Head diameter: 16mm

- Material head: Aluminium

- Material rivet mandrel: Stainless steel

- Material sleeve: Aluminium alloy AlMg3

- Head shape: Large head, round, flat

- UV resistance:Very good

- Weather resistance: Very good

- Corrosion resistance: Very good

The clamping range of the black facade rivets varies according to the chosen length and refers to the total thickness of the cladding panel and the substructure to which it is to be attached. The minimum and maximum values should neither be exceeded nor undercut in order to ensure a secure hold of the rivet.

-

Clamping area:

- Facade rivet 5x14mm: min. 5,5mm-max. 9,0mm

- Facade rivet 5x16mm: min. 7,0mm-max. 10,5mm

- Facade rivet 5x18mm: min. 9,0mm-max. 12,5mm

Assembly of panels with the black facade rivets

Facade rivets are extremely practical when a secure and inconspicuous installation of facade cladding or balcony privacy screens is required, where fixing can only be done from one side. This type of installation is usually used for existing substructures made of special aluminium profiles, which are attached to the facade to be clad in advance and are completely concealed by the facade panels after installation. Both the profiles of the supporting structure and the cladding panels are pre-drilled with a drill suitable for the material and the rivet is inserted through the panel and the substructure from the visible side. Finally, the rivet mandrel is inserted into the mouthpiece of the blind riveting pliers and tightened so that a secure connection of the two elements is achieved.

The most common panels for cladding external facades are HPL panels, fibre cement panels or aluminium composite panels. Particularly in the commercial construction of facade cladding, it is very important to ensure that the desired panel material has a facade approval. In addition, it is important to ensure that the sliding points are mounted without tension during installation. This means that during assembly by riveting, a special nose piece must be screwed into the riveting device which determines the gap distance between the rivet head and the panel, so that damage due to tensions caused by the thermal expansion of facade panels can be excluded. However, this gap distance varies depending on the material of the panel, so that our special ALU-16 gauge mouthpiece must be used for aluminium composite panels. However, this is not suitable for fibre cement panels and HPL panels. For such materials the special HPL-16 gauge mouthpiece is required.

As facade rivets, our black blind rivets are also suitable for mounting HPL panels from many other manufacturers, such as Trespa®, Kronoplan or Fundermax, but the black colour of the respective facade panels may vary slightly from manufacturer to manufacturer. The 5x16mm and 5x18mm sizes of the facade rivets are approved by the building authorities for the installation of facade cladding with HPL panels from Trespa® and Fundermax, while the smaller 5x14mm size has a corresponding approval in combination with aluminium composite panels from Alucobond and Alpolic.

For drilling the substructure we recommend our HSS-G drill with a diameter of 5.1mm. For the holes in the panel, however, a distinction must be made as to whether fixed points or sliding points are to be drilled. While the fixed point is to be drilled in the same size as the substructure, sliding points with a larger diameter of 8mm to 10mm must be drilled.

- Additional Information

Additional Information

Product-ID AFN-16XX-9005 Delivery Time Dispatch within 2-3 working days Material Aluminium (AlMg3) Rivetsize No Shape rivethead Large head, round, flat Diameter rivedhead 16mm Version various Color accuracy Production according to RAL color system Color Black RAL color code RAL9005 Color designation Jet black - Reviews