Facade rivets pure white (RAL 9010)

Our aluminium facade rivets in white (RAL 9010, pure white) are suitable for erecting facade cladding on aluminium substructures and have facade approval for aluminium composite panels and HPL panels from various manufacturers.

✓ UV and weather resistant

✓ For outdoor use

✓ White top coat

✓ Durable hold

✓ Made in Germany

The white facade rivets are available in the sizes 14mm, 16mm or 18mm at favourable graduated conditions.

The item is in stock

Dispatch within 2-3 working days

- calculate the price

- from 20 Items €0.88/ pc. (Base Price €0.88/ pc.)

- from 50 Items €0.81/ pc. (Base Price €0.81/ pc.)

- from 100 Items €0.68/ pc. (Base Price €0.68/ pc.)

- from 250 Items €0.54/ pc. (Base Price €0.54/ pc.)

- from 500 Items €0.40/ pc. (Base Price €0.40/ pc.)

All prices include 19% VAT.

0,00 € / pc.

0,0000 kg / pc.

All prices include 19% VAT.

- Description

Aluminium facade rivets in pure white (RAL 9010)

No minimum quantity ✓ Favourable graduated prices ✓ UV- and weatherproof ✓

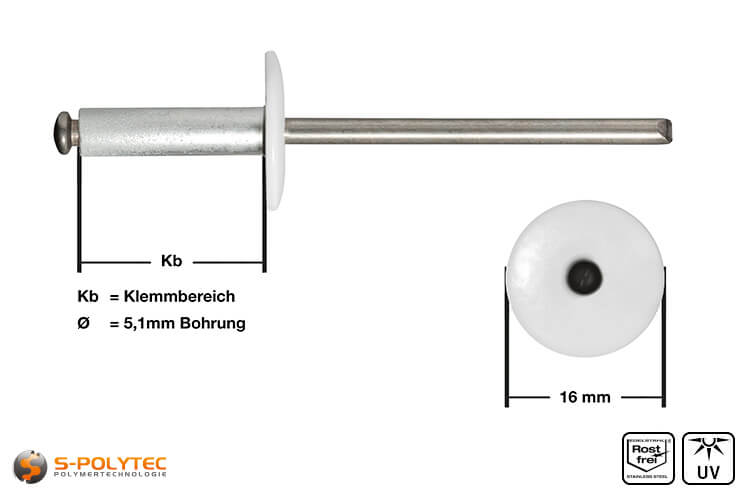

Our facade rivets in white correspond to the colour RAL9010 (pure white) and have a round, flat rivet head with a diameter of 16mm. Thanks to the facade approval, they are excellently suited for mounting HPL panels or aluminium composite panels in white as facade cladding on an aluminium substructure. The high-quality rivets are manufactured and painted in Germany and consist of two main components made of different alloys. The rivet head with sleeve is made of aluminium and the mandrel of stainless steel to guarantee a high tightening torque of the rivet sleeve. However, when the rivet is placed, this mandrel cracks at the predetermined breaking point at a fixed tightening torque and the set rivet made of aluminium remains.

We dispense with minimum purchase quantities or fixed packaging units, so that, unlike many other dealers, you have the opportunity with us to buy exactly the number of facade rivets you need for your project. Furthermore, with our graduated prices we also offer you generous quantity discounts when purchasing larger quantities.

-

Scope of delivery:

- 1 x Facade rivet with head coating in white (RAL 9010)

TIP: A suitable blind riveting tool is required for the white facade rivets.

Characteristics of our facade rivets in white

Our facade rivets have a scratch-resistant head coating in RAL 9010 (pure white), which has been matched in colour and gloss level to our HPL panels in pure white, and are therefore suitable for mounting the white laminate panels made of high-pressure laminate as unobtrusively as possible. In addition, the white rivets can also be used very well for our white aluminium composite panels or many other of our plastic panels in white, regardless of whether they are to be used as wall panelling, balcony edging or for the construction of plastic housings with riveted joints or similar. The large head diameter of 16mm ensures that even sliding point holes with a diameter of 8mm can be completely covered. The large rivet head proves to be a particular advantage in the case of plastic panels with a high coefficient of thermal expansion, where sliding points may even be required with a drill bit diameter of up to 10mm.

Our facade rivets are made of a high-quality aluminium alloy and can be used without hesitation in interior and exterior areas. To ensure that the white lacquering of the rivet head does not yellow with time, even through intensive sunlight, it is also UV and weather resistant.

WARNING: Only use our aluminium facade rivets if the substructure is also made of aluminium. In steel or stainless steel constructions, contact between the different metal alloys can lead to contact corrosion, which can have a negative effect on the appearance and quality of the rivet joint.

Technical data of white facade rivets

- Colour: RAL9010 (pure white)

- Hollow rivet diameter: 5,0mm

- Hollow rivet length: 14mm, 16mm or 18mm

- Head diameter: 16mm

- Material head: Aluminium

- Material rivet mandrel: Stainless steel

- Material sleeve: Aluminium alloy AlMg3

- Head shape: Large head, round, flat

- UV resistance: Very good

- Weather resistance: Very good

- Corrosion resistance: Very good

Depending on the rivet size, the facade rivets have different clamping ranges, the minimum and maximum values of which should be observed. The clamping range is determined by the thickness of the panels plus the thickness of the substructure.

-

Clamping area:

- Facade rivet 5x14mm: min. 5,5mm-max. 9,0mm

- Facade rivet 5x16mm: min. 7,0mm-max. 10,5mm

- Facade rivet 5x18mm: min. 9,0mm-max. 12,5mm

Assembly of panels with the white facade rivets

Blind rivets, which also include facade rivets with a large head, are always used when a metal substructure is completely covered by the panels to be mounted, so that screwing with a rear counter nut is not possible. The rivet sleeve is inserted through the hole in the panel and the substructure until the head lies flat on the surface. The mandrel is then inserted into the nose piece of the blind riveter and tightened by actuating the tool so that the rivet sleeve expands until the tightening tension is so great that the steel mandrel breaks at the predefined predetermined breaking point. However, it is very important with aluminium facade rivets that they are only used if the substructure is also made of aluminium. For steel profiles, on the other hand, rivets made of a steel alloy are required.

As facade rivets, the white large-head rivets also have facade approval in combination with panels from the major brand manufacturers. For the rivets in the sizes 5x16mm and 5x18mm with a head diameter of 16mm, for example, building authority approval is guaranteed for HPL panels of the Fundermax and Trespa® brands. The rivets in the size 5x14mm have too small a clamping range for HPL, but are approved for facade panels made of aluminium composite material from the manufacturers Alpolic or Alucobond as fixing material for facade cladding. Even if the head coating in pure white has been matched to our HPL panels in terms of colour tone and gloss level, they are by all means suitable for all white facade panels whose surface is similar to the colour tone RAL9010, but very slight tone deviations cannot be excluded in such a case.

When facade cladding is erected, HPL panels, aluminium composite panels or fibre cement panels are usually used for the panel material. These panels are subject to a certain amount of thermal expansion, so it is essential to ensure that the panels are fixed without tension during installation. This means that one fixing point should be defined as a fixed point and the remaining fixings should be carried out with a certain amount of play. To ensure this play, a special special gauge must be used when riveting the sliding points, which adjusts the gap distance between the surface of the panel and the rivet head. Depending on the material of the facade panels, a separate mouthpiece must be used. For aluminium composite panels, our special gauge mouthpiece type ALU-16 is the right choice. For HPL panels or fibre cement panels, the mouthpiece type HPL-16 must be used.

For the execution of the drillings we offer in our online shop a whole range of drills made of HSS steel or solid carbide. For our rivets, we recommend a HSS drill with a diameter of 5.1mm. This is suitable for the aluminium profiles of the substructure as well as for the fixed point drillings in aluminium composite panels. For HPL panels or fibre cement panels, our solid carbide drill Ø 6.0mm is more suitable, as it has a longer service life with such hard materials and contributes to better drill hole edges. Sliding points of the panel drill holes should be drilled with a minimum diameter of 8mm and should not exceed 10mm. Here too, depending on the plate material, a distinction must be made between HSS drills or solid carbide drills.

- Additional Information

Additional Information

Product-ID AFN-16XX-9010 Delivery Time Dispatch within 2-3 working days Material Aluminium (AlMg3) Rivetsize No Shape rivethead Large head, round, flat Diameter rivedhead 16mm Version various Color accuracy Production according to RAL color system Color White RAL color code RAL9010 Color designation Pure white - Reviews