Aluminium try square

Our anodised aluminium try squares are an essential measuring tool for tradespeople. They are used for marking, measuring and checking right angles and have measuring scales in both centimetres and inches on both sides.

✓ Made of high-quality aluminium

✓ For straight and half-straight angles

✓ Silver anodised surfaces

✓ Measuring scales on both sides

✓ Comfortable holder groove

✓ Suitable for construction sites

The high-quality flat angles with a stop are available in sizes 255x190mm or 355x190mm.

The item is in stock

Dispatch within 2-3 working days

- calculate the price

0,00 € / pc.

0,0000 kg / pc.

All prices include 19% VAT.

- Description

Högert 90° aluminium try angle

Anodised surfaces ✓ Dual-sided scale ✓ Very low weight ✓

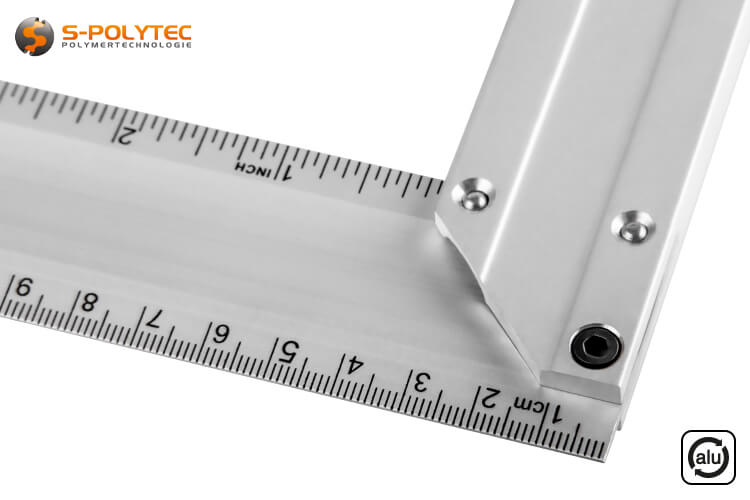

Our Högert set try squares are available in two sizes, with the more compact version measuring 255x190mm and the larger version 355x190mm. Both have an exact 90-degree angle and feature metric (cm) and imperial (inch) measuring scales on both sides of the measuring surface. This allows for application, marking and measuring on both sides. The silver-coloured try squares are made of high-quality aluminium for measuring instruments that have to meet the highest demands of craftsmen and ambitious DIYers.

All surfaces of the flat try square are anodised, which significantly improves the already good corrosion resistance of the aluminium. Since the coated aluminium does not rust even when in constant contact with rain or water, the try square is extremely useful even in harsh environments, such as construction sites. Furthermore, aluminium is very light yet robust and dimensionally stable, which ensures an extremely long service life, even with intensive use by tradespeople.

Properties of Högert aluminium try squares

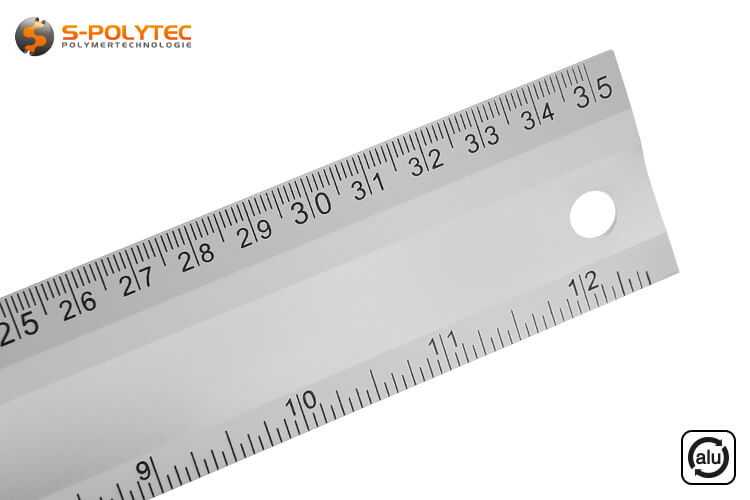

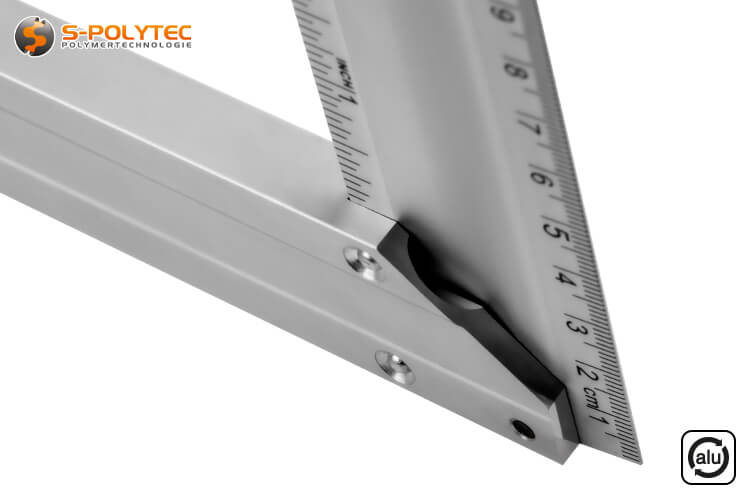

The aluminium try square has a 90° angle and is available in two different lengths. The measuring surface of the smaller try square is 255mm long and that of the slightly larger one is 355mm. The stop on both try squares is identical at 190mm, thus providing a generous surface for precise angles. The measuring surface also features two scales in centimetres and inches. The black colour of the scales contrasts very well with the silver surface and is easy to read even in poor light conditions. The try square is an almost indispensable measuring tool in the trade and is used particularly frequently by carpenters, metalworkers and joiners. The building angle is used, for example, for marking, measuring or checking right angles. However, one advantage of our carpenter's angle is that it can also be used to draw 45-degree angles, so that another angle for drawing half-right angles is not necessary.

Our try squares are made of anodised aluminium. The anodising process used for this purpose improves the corrosion resistance of the aluminium and at the same time serves to enhance the surface appearance, giving it an even silver colour with a fine metallic look. Thanks to the high-quality aluminium alloy from which the try squares are made, they are extremely rigid. The handle, which serves as a stop, and the measuring surface are connected by two solid rivets, ensuring that the two legs are firmly attached to each other. However, it is not only professional users from a wide range of trades and industries who benefit from the high quality, but also DIY enthusiasts with high quality standards.

Our low-angle try squares with shoulder have some helpful additional features, such as the holding groove in the centre of the measuring surface. This is a depression in the surface that makes it easier to hold the aluminium stop bracket when measuring or marking on a surface. With the stop's already large contact surface, which has a width of 40mm, the recess makes it highly unlikely that the measuring tool will slip. In addition, the try square has an inconspicuous hole at the outer end of the measuring surface. This has several useful properties. On the one hand, it serves as a fixing device, as the measuring tool can be temporarily secured against slipping on the workpiece by means of a screw, nail or pin through the hole. On the other hand, the hole can also serve as a guide point for marking arcs, circles or selected points. This is also done by inserting a pen or a drawing pin through the hole. Finally, the hole can be used as a hanging point for practical storage in the workshop, thus creating order in the company, the hobby room or the garage. Last but not least, a simple grub screw in the outer angle of the leg connection ensures increased strength and can also be used for recalibration purposes.

Specific data on Högert aluminium stop brackets

- Try square 255x190mm: Dimensions (WxDxH): 255x190x12mm, angle: 90 degrees, scale: 25cm/8.5in; weight: 169g

- Try square 355x190mm: Dimensions (WxDxH): 355x190x12mm, angle: 90 degrees, scale: 35cm/12.5in; weight: 193g

Use and handling of low-angle try squares with a stop

Set squares are a great help for tradespeople and DIYers in countless applications. There are three basic functions. First and foremost, a set square is used to mark right angles on surfaces or to check squareness after cutting or assembly. Since the flat angle with stop also has two-sided measuring scales, it is also suitable for measuring short distances on even surfaces. However, before you start marking, measuring or checking angles, it is advisable to remove coarse dirt from the surface of the workpiece. This ensures an even surface, which is essential, as only in this way can precise measurements be carried out.

The try square is used to precisely mark 90-degree angles. A pencil, ballpoint pen or marking crayon is used to draw a line along the measuring surface on a wooden board, a wall or on panels, which is used for orientation during assembly or cutting. When marking on metals such as aluminium, iron or steel, this is usually done by scribing with the help of a scriber. Before you can use the try square for marking or tearing, the exact position must be measured. Subsequently, the flat angle with the stop can be applied to this position. Whether the top or bottom of the measuring surface is used is of secondary importance, as long as there is a sufficiently large contact surface. The handle with the double-sided overhang serves as a stop and must be held firmly against the edge of the board, beam or square tube so that it rests against the edge along its entire length. Otherwise, a right angle cannot be guaranteed. It is essential that the bevelled angle square is placed on a clean and even surface. This is also of great importance when exact angles have to be maintained. When marking, the aluminium angle should be firmly held with one hand to prevent it from slipping. However, the recess within the measuring surface makes it much easier to hold when marking.

Another task is to check 90-degree angles. To do this, the try square is placed on the selected angle with the wider handle. It does not matter whether it is an internal or external angle. If both sides are flush with the angled surface to be checked, without a gap being visible, it is an exact 90-degree angle. When testing external angles, if there is a gap at the outer end of the measuring surface, the angle is less than 90 degrees. If, on the other hand, the gap is at the beginning, the measured angle exceeds 90° of a right angle. When testing the perpendicularity of internal angles, the opposite applies, so that a gap at the end of the measuring scale indicates an excessive angle. However, care should always be taken to ensure that the flat angle is held straight with the stop, as only then will an accurate result be achieved.

NOTE: Our aluminium try square is not only suitable for measuring right angles, but also has another function. The handle does not end straight at the measuring surface, but has been deliberately cut at a 45-degree angle so that the stop can also be applied over this edge. This way, the try square can also be used for 45-degree markings and measurements.

Carpenter squares are often used by carpenters to mark out boards, table tops or steps and to achieve precise cuts. But the try square is also useful in interior design, because when installing interior doors it is often necessary to check whether the door frame has been properly inserted before foaming, so that it later fits perfectly with the door leaf. If this is not the case, the door will open and close on its own. In the construction industry, the try square is used to take and transfer exact angle measurements based on blueprints and drawings, so that angles are precisely maintained before concrete is poured during the construction of formwork for concrete ceilings and walls. In addition, the try square is also used by roofers, as the construction angle is helpful, for example, when positioning roof battens to ensure professional roof covering in which the individual rows of tiles are perfectly spaced. Furthermore, the flat angle with shoulder is also valued in metal construction. There, on the other hand, the aluminium try square is often referred to as a locksmith's angle. In this industry, the angle is used to check welded joints in steel girders or welded staircases and balcony railings. A try square is also helpful before welding to mark the exact markings on the metal, which are later needed for precise cuts.

The try square is also useful in the home and in the domestic workshop. It is often used when laying laminate or tiles, as the try square is perfect for marking the planks perfectly and straight so that they are flush with the wall. The situation is similar for skirting boards, which are often only cut to size by eye. This can quickly result in unsightly butt joints. Marking with a try square helps to avoid this. For corner connections of skirting boards, the point where the skirting boards meet is determined beforehand, which is exactly 90 degrees in most inner and outer corners. With the help of the try square, this angle can be determined with millimetre precision and the mitre cut can be carried out correctly. Furthermore, the flat angle with approach is also extremely helpful when building or repairing furniture, as it can be used to ensure that corners and connections of shelves, cabinets or tables are at right angles. It thus ensures precise assembly through the correct alignment and positioning of the furniture carcasses. The try square is not only useful for building and repairing furniture, but also for realising your own DIY projects. For example, the aluminium try square is used to build a shelter for garbage cans made of construction profiles, since these should not only be screwed together for a good hold, but should also be at right angles to each other. Using our aluminium stop angle, the necessary control is quickly done and the shelter for garbage cans is ready to go.

Examples of how to use aluminium stop angles

- When cutting edging for floor coverings to size, an angle helps to achieve perfect butt joints

- Carpenters use try squares to ensure that furniture boards, drawers and doors are perfectly angled

- A metalworker uses metalworker's squares to check whether two metal pipes have been welded together at right angles

- The try square is used to check the squareness of the saw blade to the table for precise cuts

- Carpenters use try squares to mark and check the exact position of the steps on the stringers

Technical data for Högert aluminium try squares

- Product type: Measuring tool

- Material: Aluminium (anodised)

- Colour: Silver

- Measuring angle: 45°/90°

- Scale: Metric, Imperial (on both sides)

- Total length: 255mm or 355mm

- Weight: 169g or 193g

- Grip width: 34mm

- Grip depth: 12cm

- UV-resistance: Excellent

- Weather resistance: Excellent

- Corrosion resistance: Excellent

- Additional Information

Additional Information

Product-ID SAL-00 Delivery Time Dispatch within 2-3 working days Property Measuring tool Material Aluminium (anodised) Color Silver - Reviews