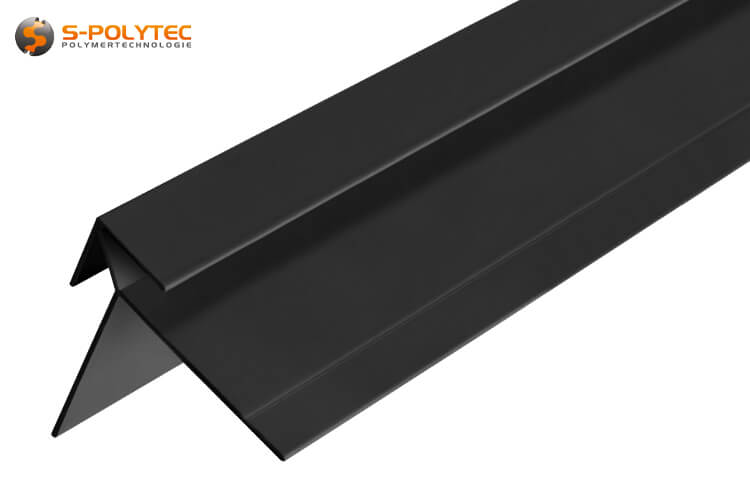

Aluminium outside corner profile anthracite (RAL 7016)

The corner profiles for external corners in anthracite aluminium are UV and weather resistant and can be used for cladding facade corners outdoors. Thanks to the manufacture from AW 6063 T6 aluminium, the profiles are enormously stable and corrosion-resistant.

✓ Powder coated in anthracite

✓ Solid 6063 T6 aluminium

✓ UV & weather resistant

✓ Suitable for outside corners

✓ Very high stability

✓ Silk matt surfaces

The anthracite grey outer corner profiles are available from us with 3mm, 6mm or 8mm clamping range at favourable graduated prices.

The item is in stock

Dispatch within 2 - 3 working days

- calculate the price

- at pieces 0,00 € (Base Price 0,00 € / m)

- at pieces 0,00 € (Base Price 0,00 € / m)

- at pieces 0,00 € (Base Price 0,00 € / m)

All prices include 19% VAT.

0,00 € / pc.

0,0000kg / pc.

All prices include 19% VAT.

- Description

Aluminium corner profiles in anthracite (RAL7016) for outside corners

Weatherproof powder coating ✓ Solid aluminium ✓ Corrosion-resistant ✓

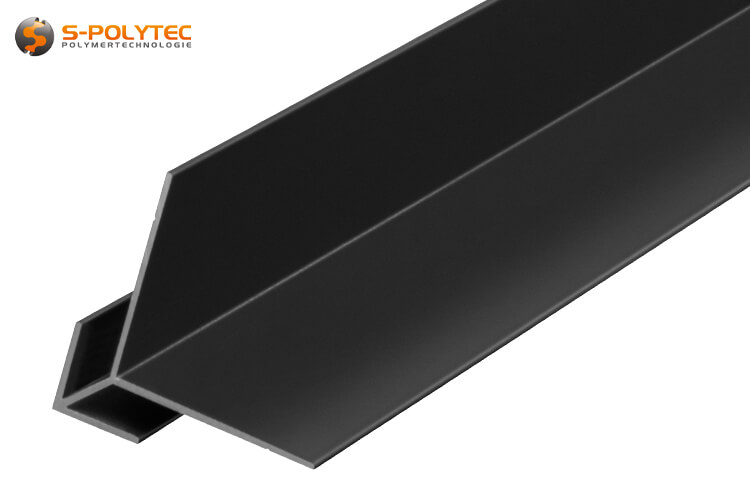

Our aluminium corner profiles for external corners are made of solid aluminium with a profile thickness of 1.1mm and subsequently coated with a robust powder coating in anthracite (RAL 7016). The profiles, whose colour and gloss level are matched to our HPL panels in anthracite, are available in 3mm, 6mm and 8mm clamping ranges. This means that, depending on the version, the profiles are not only suitable for HPL in 6mm or 8mm, but also for our 3mm aluminium composite panels in anthracite or for designer vinyl floors, which usually have a thickness of 2-3mm. The 6mm profiles are also very suitable for wall tiles or floor coverings made of click laminate, whereas the profile with 8mm clamping range also has a very good thickness for floor tiles to achieve a visually perfect corner finish. The aluminium alloy AW EN 6063 T6 aluminium is an extremely corrosion-resistant alloy. The lacquering of the surface is also UV and weather resistant, so that the corner profiles are permanently suitable for outdoor applications. Of course, the corner profiles are also suitable for all indoor applications without hesitation, for example as corner connecting profiles of wall claddings, partition walls or as edge coverings of stair treads.

We use a 6063 T6 aluminium alloy for our aluminium profiles, which allows us to choose a low profile thickness without having to accept any losses in terms of stability. The profile thickness of only 1.1mm has a very high inherent rigidity and at the same time ensures a very low weight, so that the corner profiles hardly contribute significantly to the weight load of façade cladding on the substructure. In addition, the thin-walled profiles have the advantage that they can be processed very easily. Cutting the profiles to length, for example, can easily be done with a simple hand saw. The small difference in height from the panel surface to the surface of the profile is also a noteworthy aspect, as this not only contributes to a more inconspicuous overall appearance, but also facilitates the occasional cleaning of the surfaces with a soft cloth.

NOTE: Our corner profiles for external corners with robust powder coating in anthracite grey (RAL7016) are available with a standard length of 2000mm as versions with a clamping range of 3mm, 6mm or 8mm. Corner profiles for inside corners, connecting profiles or edge trim profiles are also available in the same colour. We also offer these as 2-metre lengths for panel thicknesses of 3mm, 6mm or 8mm.

Properties of the external corner profile in anthracite grey

Our corner profiles, like all our aluminium profiles, are made of high-quality EN AW 6063 T6 aluminium. The advantages of this alloy, which is also colloquially known as architectural aluminium in the building sector, are very good corrosion resistance and high inherent rigidity with comparatively low weight. Solid aluminium is a very good material, especially for our optical profiles, which are used both for façade cladding outdoors and in interior design, for example for partitions and screens. It combines a filigree appearance with high bending stiffness and thus improves the stability of constructions, for example for free-standing partitions or room dividers, especially with low panel thicknesses. Instead of a protective layer by anodic oxidation, as is used with our silver anodised profiles, we use a scratch-resistant powder coating in RAL 7016 with a gloss level of approx. 20% for the anthracite grey corner profiles, which is characterised by good UV and weather resistance. This means that the surface of the profiles is exactly the same in colour and gloss level as the surface decor of our HPL panels in anthracite grey, which we offer cut to size to the millimetre and are therefore ideal for covering the edges of façade cladding outdoors without having to fear colour changes due to weathering.

We stock the corner profiles in the three most common clamping ranges that are common for cladding panels. This clamping range depends on the selection and is 3mm, 6mm or 8mm. The maximum clamping range, on the other hand, is slightly different and was deliberately chosen higher in the design of the profiles so that panel material with higher manufacturing tolerances in relation to the panel thickness can also be used. The plus tolerance of the maximum clamping range is approx. 0.5mm for all profiles, resulting in 3.5mm, 6.5mm or 8.5mm. The profile thickness of approx. 1.1mm is also identical for all external corner profiles. The dimensional accuracy of our profiles is based on the EN 12020 standard (extruded precision profiles made of EN AW-6060 and EN AW-6063 alloys), compliance with which is guaranteed by strict controls carried out by our manufacturer based in North Rhine-Westphalia (Germany). This enables us to guarantee a consistently high quality of our aluminium profiles.

However, there are also differences in the profiles that are due to the different clamping areas. On the one hand, this refers to the visible outer surface of the profiles, as well as the width of the mounting surface, which also results in changes in the overall dimensions. The visible surfaces of the corner profiles arranged at right angles to each other have a width of approx. 14.5mm for the 3mm profile. For the 6mm profile, the width is approx. 15.0mm. For the 8mm profile, this increases again to approx. 17.0mm. The mounting surface, which is used for gluing or screwing if required, has a width of 35mm for the two larger profiles. In the case of the 3mm corner profiles, this is somewhat more generous at 38mm and results in an increase in stiffness, which is not given to a sufficient extent in the case of most panels in this low thickness.

Specific data of the different profile sizes

- Alu corner profile for outside corners 3mm: Clamping range: max. 3.5mm, profile depth outside: 44.0mm, weight: 329g/m

- Alu corner profile for outside corners 6mm: Clamping range: max. 6.5mm, profile depth outside: 43.5mm, weight: 321g/m

- Alu corner profile for outside corners 8mm: Clamping range: max. 8.5mm, profile depth outside: 46.0mm, weight: 345g/m

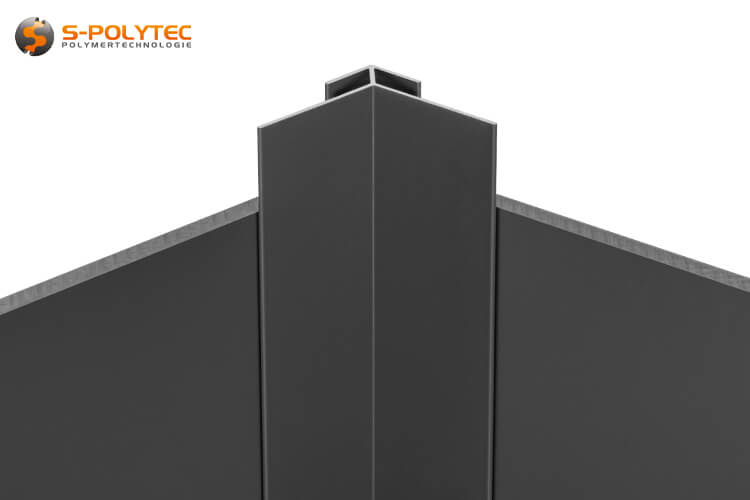

Application and assembly of the aluminium corner profiles in anthracite

The corner profiles for external corners with anthracite grey powder coating are perfect for covering the edges of façade cladding and conceal chipped edges from sawn edges on HPL façade panels and also cover the dark core of HPL decorative panels or aluminium composite panels, which in the latter case is due to the black core made of PE plastic. Apart from the optical reasons for using the corner profiles, they also reduce injuries from cut edges, which can be extremely sharp, especially with wall and floor tiles, but also with aluminium composite panels. Depending on the area of application, the corner profiles are pushed over the edges of the cladding panels. The easiest way to do this is to insert the profiles and only then continue with the panel assembly at right angles. If the profiles are used as the corner finish of the wall and flooring, it is recommended that they are fixed to the wall corner with a suitable installation adhesive and that the tiles or laminate are not fitted until they have hardened. While laminate or vinyl can certainly be fitted into the profile rail, a joint between the visible area of the corner profile and the surface of tiles usually looks more pleasing. The joint created in this way can later be easily sealed with a colour-matched silicone and seals the finish perfectly.

TIP: With a standard length of 2 metres, the anthracite grey external corner profiles are extremely well suited for large claddings of external facades. For shorter panel ends around an external corner, the thin but solid profiles can be easily cut with a metal saw, but a mitre saw with mitre function is a much better alternative, as this ensures clean, straight cuts of the aluminium profiles.

The powder-coated profiles for external corners have a good clamping force with panels whose thickness corresponds to the maximum clamping range, without the need for additional fixing. Depending on the specific material, thickness tolerances are not unusual in the manufacture of the panels. These tolerances can vary from manufacturer to manufacturer. For this reason, our profiles also have a plus tolerance of approx. 0.5mm, so that they can be pushed onto the panel edges at any time. In some applications, especially for panels with a smooth, even surface, additional fastening by gluing or screwing can be helpful. In most cases, an MS polymer, such as our Parabond 600, is a very good choice, because this permanently elastic mounting adhesive adheres to almost all materials commonly used in the construction sector. A small indentation on the mounting surface serves equally as a guide for the application of the adhesive and also results in better adhesion. In addition, the groove can also be used to maintain the distance for drilling holes if the profiles are to be attached with suitable screws. The distance on the mounting surface is chosen so that no edge chipping of the panel material is to be expected when fastening with screws. For drilling the thin outer corner profiles, a metal drill bit, for example our ground HSS drill bit, is the perfect choice, and glides effortlessly through the thin-walled aluminium.

Application examples of our profiles for outside corners made of aluminium

- The aluminium external corner profiles in anthracite are perfect for finishing the corners of dark HPL panels outdoors

- The outside corner profiles are excellently suited for the erection of weatherproof enclosures for garden tools or waste bins

- The profiles in RAL7016 can also be used as inner corner profiles with the wider surface as visible side

- The robust powder coating of the profiles is not affected by cleaners in the bathroom, WC and kitchen

- External corner profiles in anthracite grey are well suited for free-standing room dividers in offices and shops

Technical data of the aluminium corner profiles in anthracite

- Material: Anodised aluminium

- Alloy: EN AW 6063 T6

- Surface: Powder-coated

- Colour: Anthracite grey (RAL 7016)

- Profile shape: Corner profile (outer corner profile)

- Clamping range (max): 3,5mm, 6,5mm resp. 8,5mm

- Standard length: 2005mm

- Corner profile (outer corner profile): 1,1mm

- Sight width: 14,5mm - 17,0mm

- Profile width: 43,5mm - 46,0mm

- Mounting surface: 35,0mm - 38,0mm

- UV-resistance: Excellent

- Weather resistance: Excellent

- Corrosion resistance: Excellent

- Additional Information

Additional Information

Product-ID AP-010 Standart Length 2000 Delivery Time Dispatch within 2 - 3 working days Material Aluminium (EN AW 6063 T6) Profile type Outside corner profile Version varies Color Grey Color accuracy No information available Color designation Anthracite grey - Reviews