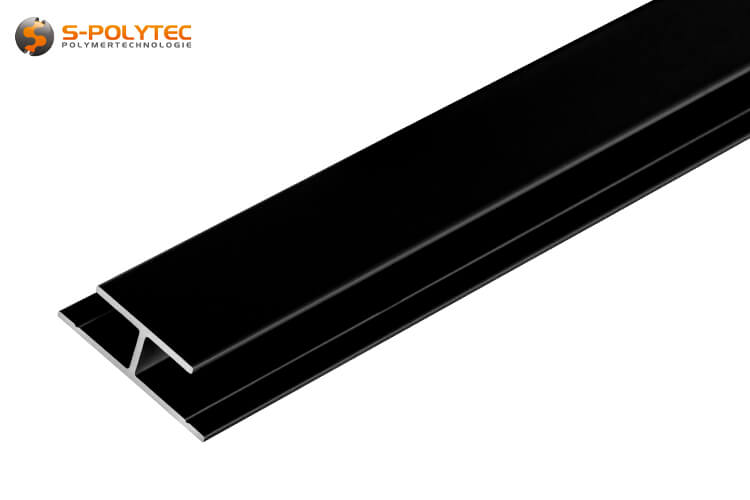

Aluminium H-profile black (RAL 9005)

The aluminium H-profiles with all-round powder coating in black (RAL 9005) are ideal for bridging gaps in panels made of HPL or aluminium Dibond® and cover cut edges on both sides. Made from corrosion-resistant aluminium, the H-profiles are suitable for indoor and outdoor applications.

✓ Weatherproof powder coating

✓ EN AW 6063 T6 Aluminium

✓ Ideal for outdoor use

✓ UV-resistant coating

✓ Very stable and lightweight

✓ Silk matt surface

We offer the connecting profiles in black with a choice of 3mm, 6mm or 8mm clamping range at attractive graduated prices.

The item is in stock

Dispatch within 2-3 working days

- calculate the price

- at pieces 0,00 € (Base Price 0,00 € / m)

- at pieces 0,00 € (Base Price 0,00 € / m)

- at pieces 0,00 € (Base Price 0,00 € / m)

All prices include 19% VAT.

0,00 € / pc.

0,0000kg / pc.

All prices include 19% VAT.

- Description

Aluminium H-profiles in black for covering gaps

Black powder coating ✓ For indoors and outdoors ✓ Extremely rigid ✓

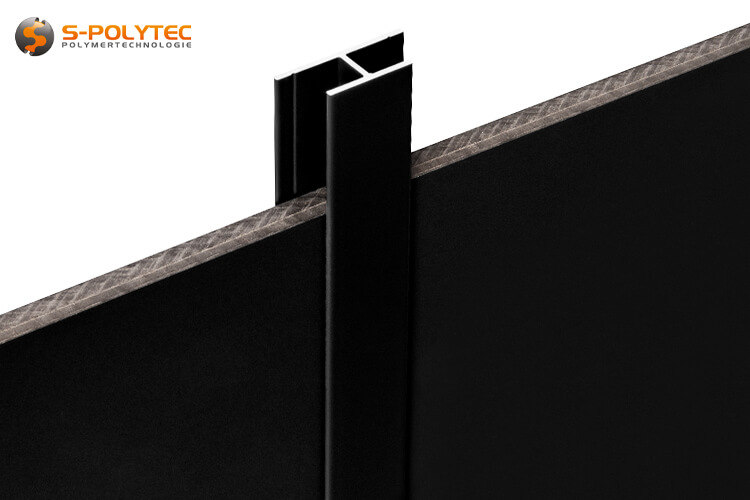

Our H-profiles in black are available for panels with a thickness of 3mm, 6mm or 8mm. The satin matt surface in rich black corresponds to the RAL colour RAL9005 and is therefore perfectly matched to our black HPL panels made to measure. This is a particularly resistant powder coating that does not fade even when exposed to strong sunlight. The lacquered H-profiles made of solid aluminium are edge-covering on both sides. This means that cut edges, as well as the different coloured core of Alu-Dibond® or HPL façade panels, are covered on both sides in a simple and efficient way. However, the corrosion and UV-resistant profiles are not only ideal for exterior wall panelling, but are also extremely suitable for exhibition stand construction, furniture construction or interior design.

Aluminium combines the advantages of high inherent rigidity with low weight. This is particularly important for large façade systems with usually heavy façade panels made of HPL or fibre cement, so that the weight load on the substructure and the masonry behind it is not significantly increased. Thanks to an extremely high-quality EN AW 6063 T6 aluminium alloy, a very thin profile thickness of just 1.1 mm is possible with the same stability. This has a positive effect on the visually unobtrusive transition from the profile to the panel surface and also makes it much easier to clean the surfaces because the very thin profile edges can hardly accumulate any dirt.

NOTE: Our black H-profiles are available in different clamping ranges and lengths and can be ordered for panel thicknesses of 3mm, 6mm or 8mm. The matching end profiles in RAL 9005 are also available in these three clamping ranges in lengths of 2 metres or 1 metre at favourable prices.

Properties of the H-profile with powder coating in black

Our H-profiles are perfect for bridging gaps in vertical façade cladding with our black HPL panels, as they match perfectly in terms of colour and gloss level. To achieve this, we use a surface finish with a robust powder coating consisting of a special paint that is characterised by excellent resistance to UV radiation and weathering. There is no need to worry about fading due to prolonged exposure to the elements. The façade cladding therefore remains attractive and attractive over a long period of time. By choosing high-quality 6063 T6 aluminium, which has outstanding corrosion resistance, nothing stands in the way of long-term outdoor use. This material combines very good rigidity with a low weight, as this special alloy, which is also known as architect aluminium, allows us to achieve lower profile thicknesses with similar strength values compared to some other aluminium alloys. The black profiles for panel connections also cut a very fine figure in countless interior design applications and impress with their ease of processing.

With the three different clamping ranges of 3mm, 6mm or 8mm, we offer our black H-profiles in the typical sizes that are common for interior and exterior wall panelling. These include aluminium composite panels with a thickness of 3mm for interior fittings, as well as HPL panels with a thickness of 6mm or 8mm. To ensure that the use of the profiles is not limited to the panels in our shop, they are manufactured with a tolerance that results in a maximum clamping range of 3.5mm. This is necessary because, depending on the specific material and manufacturer, the panel thicknesses can vary in their nominal thickness. We also play it safe with the length and have the connecting profiles manufactured with a plus tolerance of 5mm, as this ensures that the length never falls below 2 metres when the black profile is ordered in the standard length. When one metre lengths are ordered, we cut them to the required size using a special Kaltenbach profile saw. Our cutting tolerance here is one millimetre.

Although our aluminium profiles with double insertion have a clearly defined front side and a rear side that is slightly wider for optimised installation according to the design drawing, they can also be installed with the rear side as the visible side if desired. This is made possible by the all-round powder coating in deep black. It is therefore a question of personal taste whether the 17 mm wide front or the slightly wider 26mm surface is used as the visible side. It is even possible to install both sides as a visible side, for example for privacy screens between two neighbouring balconies or terraces. These dimensions, as well as the asymmetry, are identical for all three clamping areas. The material thickness of the solid aluminium profiles is also always 1.1 mm, regardless of the design, resulting in different profile depths. This is calculated from twice the profile thickness, which must be added to the maximum clamping range. For a 3mm H-profile with a maximum clamping range of 3.5mm, this means a total profile depth of 5.7mm. Compliance with these dimensions is subject to constant quality control by our German manufacturer based in North Rhine-Westphalia, which ensures production in accordance with our design drawings using the extrusion process in compliance with EU standard EN 12020.

Specific data for the different profile sizes

- Aluminium H-profile 3mm: Clamping range: max. 3.5mm, profile depth outside: 5.7mm, weight: 138g/m

- Aluminium H-profile 6mm: Clamping range: max. 6.5mm, profile depth outside: 8.7mm, weight: 147g/m

- Aluminium H-profile 8mm: Clamping range: max. 8.5mm, profile depth outside: 10.7mm, weight: 153g/m

Application and installation of the black aluminium H-profiles made of aluminium

To ensure that the connecting profiles are completely black on the visible side, they are powder-coated from all sides deep into the profile. Among other things, this also allows upside-down use with the reverse side as the visible side and has the decisive advantage that even coarser edge chipping, which can occur when cutting HPL decorative panels with a saw blade that is too coarse, is concealed. Even insufficiently straight cut edges are visually levelled and straightened by an H-profile. In ventilated façade systems, the profiles are simply slid between the panels or attached to the edge before the second panel is installed. Additional fixing by gluing or screwing is not necessary here and can even have a detrimental effect on the expansion capacity of a constraint-free installation with HPL, fibre cement or aluminium composite panels. Indoors, for example in partition walls or in the sanitary area as a transition from the shower rear wall to the wall tile, there is no risk of this, so the profiles can also be fixed with suitable means for a better hold.

TIP: The satin matt profiles with black powder coating are available from us in either 2 metre or 1 metre lengths. If it is necessary to shorten them, a chop saw is the best option for a precise, straight cut. However, a handsaw will also do, as the low profile thickness means that this can also be done very quickly and almost effortlessly. To ensure that the painted surface is not damaged when sawing, a little masking tape can be helpful by sufficiently covering the area to be sawn with the tape.

Whilst clip-on is the ideal method of mounting our H-profiles for façade panels, additional fixing to prevent slippage or loosening can be helpful for specific applications. Gluing the profiles can provide additional stability, especially for free-standing installations, such as in exhibition stand construction to separate individual exhibition walls or consultation areas, as well as in open-plan offices. It is also possible to screw them together to secure them, for example for privacy screens in WC areas in the catering industry. For this purpose, the profiles are equipped with an inconspicuous small groove within the mounting surface. This also serves as a guide for the application and optimisation of the bonding using a powerful MS polymer as a mounting adhesive. The groove is also helpful for positioning the drilled holes and ensures the ideal spacing of the screws in the panel without the risk of the screws being screwed in too close to the edge of the panel, which, depending on the material, can result in edge chipping in the panel. We recommend an HSS drill bit for drilling the profiles, which should be selected depending on the diameter of the screw.

Application examples of our black aluminium end profiles

- The deep black of the aluminium H-profiles is colour-coordinated with our black HPL panels made to measure

- The connecting profiles are ideal for improving the stability and flexural rigidity of partition wall systems

- The profiles are also suitable for creating a transition from wall tiles to mirrors or the shower rear wall

- The H-profiles are perfect for connecting back walls or kitchen plinths in trendy black

- The black aluminium profiles can also be used well in contrast with light or coloured panel materials

Technical data of the aluminium H-profiles in black

- Material: Anodised aluminium

- Alloy: EN AW 6063 T6

- Surface: Powder-coated

- Colour: Deep black (RAL 9005)

- Profile shape: H-profile (Connection profile)

- Clamping range (max): 3,5mm, 6,5mm resp. 8,5mm

- Standard length: 2005mm

- Profile strength: 1,1mm

- Visible width: 17,0mm

- Profile width: 26,0mm

- Mounting surface: 12,45mm

- UV-resistance: Excellent

- Weather resistance: Excellent

- Corrosion resistance: Excellent

- Additional Information

Additional Information

Product-ID BPH-00 Standart Length 2000 Delivery Time Dispatch within 2-3 working days Material Aluminium anodised Profile type H-Profile Version 3mm - 8mm Color Black Color accuracy Color similar to RAL color system RAL color code RAL 9005 Color designation Deep black - Reviews