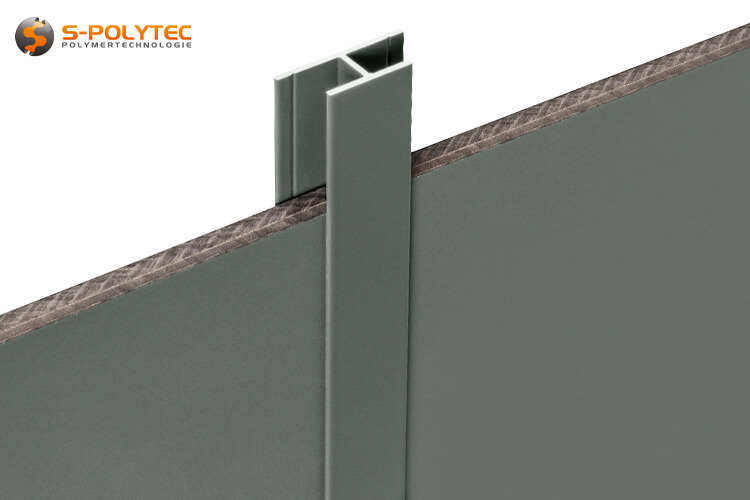

Aluminium H-profile dusty grey (RAL 7037)

The H-profiles in dusty grey (RAL 7037) are ideal for covering the edges of two adjoining panels and are suitable for long-term outdoor use thanks to their corrosion-resistant aluminium construction with UV-resistant powder coating.

✓ Powder-coated all round

✓ EN AW 6063 T6 Aluminium

✓ Suitable for indoor & outdoor use

✓ Closes cold bridges

✓ Very high rigidity

✓ Smooth surfaces

The high-quality H-profiles in dusty grey (RAL 7037) can be ordered with either a 3mm, 6mm or 8mm clamping range.

The item is in stock

Dispatch within 2-3 working days

- calculate the price

- at pieces 0,00 € (Base Price 0,00 € / m)

- at pieces 0,00 € (Base Price 0,00 € / m)

- at pieces 0,00 € (Base Price 0,00 € / m)

All prices include 19% VAT.

0,00 € / pc.

0,0000kg / pc.

All prices include 19% VAT.

- Description

Aluminium H-profiles in dust grey (RAL7037)

Silky matt sheen ✓ 100% weatherproof ✓ For indoor and outdoor use ✓

Our H-profiles made of powder-coated aluminium in dusty grey (RAL 7037) are manufactured from a particularly resistant aluminium alloy (EN AW 6063 T6) and therefore have outstanding resistance to corrosion. Properties that are of great importance for a façade profile that is specially adapted to our dust grey HPL sheets in terms of colour and gloss effect. The powder coating, which is also UV and weather-resistant, also impresses with its scratch resistance. We offer the H-profiles optionally for panel thicknesses of 3mm, 6mm and 8mm, as well as in lengths of 1000mm or 2000mm at favourable graduated prices. The areas of application are very wide-ranging, as the profiles also impress indoors with their neutral colour and durability. The solid aluminium profiles are suitable, for example, as a visual connecting element for wall panelling behind the TV or in the shower, in changing rooms, as well as for bridging gaps in kitchen or furniture rear walls.

Our connecting profiles, as well as our U-profiles, are made of robust extruded aluminium with a material thickness of 1.1mm. This has many advantages. First and foremost, due to the low dead weight, the total weight of a connection between two panels is not significantly affected by the profile. Furthermore, from a certain distance, the profile hardly stands out from the panel surface at all, as the 1mm protrusion of the profile does not cast a significant shadow. This creates a fluid overall appearance of the panel joint. Another advantage to this is the ease of cleaning, which is much simpler. Due to the narrow edge, hardly any dirt can accumulate in it. However, stability does not have to be sacrificed, as all profiles are made of pure EN AW 6063 aluminium to achieve a high degree of rigidity.

NOTE: In addition to the H-profiles, which are available in either 3mm, 6mm or 8mm clamping thickness, there are also matching end profiles with a paint finish in exactly the same colour, so that the wall cladding not only has a high-quality finish between the panels, but also on the outer edges. All dusty grey connecting profiles are available in the production length of 2005mm or cut to one metre.

Properties of the H-profile with powder coating in dusty grey

The dusty grey aluminium profiles for connecting panels are matched in colour and gloss level to our high-pressure laminates of the same colour and have a wide range of indoor and outdoor applications. As a connecting profile that can be used for façade systems in unprotected outdoor areas, reliable resistance to corrosion is extremely important. For this reason, they are made from a very high-quality EN AW 6063 T6 aluminium alloy. Another aspect for durable outdoor use is the powder coating in dust grey, which is why we use a special paint that impresses with its outstanding resistance to UV radiation and weathering. This ensures that the profile remains dust grey even in intense sunlight and prevents fading. The profile is manufactured using an extrusion process with a profile thickness of 1.1mm. Despite the relatively low profile thickness, the solid H-profiles have a high inherent rigidity, which significantly improves the bending rigidity of thin sheets.

The clamping ranges for the H-profiles vary depending on the selection. The clamping range for the profiles can be selected between 3mm, 6mm or 8mm. However, the actual clamping range is 0.5mm higher. Deviations in panel thickness are common, especially with large panel formats, such as those usually used for façade cladding. Depending on the material and manufacturer, the production tolerances of the boards can vary. For this reason, the plus tolerance of 0.5mm is important to ensure that the profiles can always be easily fitted to the panel edges. The production length of the aluminium profiles is 2005mm. With the excess length of 5mm, we ensure that the profiles never fall short of the 2000mm length. If the profiles are ordered in a length of 1000mm, we shorten them to the ordered size. We have a state-of-the-art profile saw from Kaltenbach at our site in Kranenburg for this purpose.

Our H-profiles are designed asymmetrically. This means one wider and one narrower side. Both sides are parallel to each other and can be used as a visible side, depending on personal taste. All outer sides, as well as the mounting surface, are powder-coated in dust grey. The wide side serves as a mounting surface on the inside and has an external width of 26mm. The front side is significantly narrower at 17mm. This applies to all our H-profiles for façade panels, regardless of the colour or the clamping area. The material thickness of 1.1mm is also the same for all connecting profiles, so that the total profile depth ranges from 5.7mm for the 3mm H-profile to 10.7mm for each with an 8mm clamping range. The H-profiles made of high-quality aluminium are manufactured using the extrusion process in accordance with EU standard EN 12020. This is carried out by our German manufacturer based in NRW, which guarantees a high level of quality assurance and compliance with this standard. Constant checks are also carried out with regard to dimensional accuracy and colour fidelity so that our connecting profiles are always produced in the same colour and gloss level. All of this is repeatedly confirmed by our in-house inspection of incoming goods in order to guarantee consistent and high product quality.

Specific data for the different profile sizes

- Aluminium H-profile 3mm: Clamping range: max. 3.5mm, profile depth outside: 5.7mm, weight: 138g/m

- Aluminium H-profiles 6mm: Clamping range: max. 6.5mm, profile depth outside: 8.7mm, weight: 147g/m

- Aluminium H-profiles 8mm: Clamping range: max. 8.5mm, profile depth outside: 10.7mm, weight: 153g/m

Application and installation of the dust-grey aluminium H-profiles made of aluminium

The powder-coated aluminium profiles in dusty grey have an even, satin-finish surface. This enhances the smooth surfaces of the extruded profiles, as longitudinal stripes with varying degrees of gloss would be visible on untreated profiles. Dusty grey is one of the most sought-after colours in interior design and for façade panels, as it can be combined with almost any other colour and also harmonises very well with white or black and provides an attractive contrast. The H-profiles are very easy to work with and can be fitted before the second panel is installed or inserted into the gap afterwards. As a wall profile in the bathroom, they can simply be inserted between the wall panelling panels or glazing. An additional seal with silicone sealant prevents moisture from penetrating, so that the masonry behind them remains dry and no mould can form, even during extended showers.

TIP: Depending on the selection, the connecting profiles for façade panels are supplied in 2005mm lengths or cut to 1000mm lengths. However, cutting the profiles to size is child's play due to their low thickness and can be done with a conventional hacksaw. Shortening is somewhat more convenient and precise with a cross-cut saw, if this is available. To avoid scratching the dust-grey powder coating during sawing, we recommend masking the area where the saw blade has to be applied with some masking tape.

The connecting profiles can be attached, glued or screwed in the same way. Which of these installation methods is the best depends on the intended use. Particularly in the case of large-area wall claddings with HPL panels or aluminium Dibond® that are subject to thematic expansion, the optical profiles should not be attached using screws or mounting adhesive. This is important due to temperature fluctuations so that the panels can continue to react to them. As a connecting element in interior areas, for example for wall panelling instead of tiled mirrors, kitchen or shower splashbacks, the wider inner surfaces of the H-profiles, which are dedicated to the substrate, can be glued on with a suitable adhesive, for example an MS polymer. A wafer-thin groove on the inside of the mounting surface also serves as a guide for applying the adhesive sealant and optimises the service life of the joint itself. If, on the other hand, you prefer screwing, you will need a cordless screwdriver and a small-diameter HSS drill bit, as our profiles are not pre-drilled. The filigree groove can also be helpful here to ensure that the edge distance of the screw is perfect and even.

Application examples of our dusty grey aluminium connecting profiles

- The weather-resistant connecting profiles are ideal for vertical façade systems with our HPL panels

- The 3mm connection profiles are perfect for increasing the bending stiffness of thin panels with a thickness of 3mm

- The corrosion-resistant connecting profiles are also suitable for connecting shower walls in the bathroom

- The connecting profiles in dust grey are suitable for fence systems and privacy screens in outdoor areas

- The dust grey H-profiles are great for connecting privacy screens, changing rooms or furniture back panels

Technical data of the aluminium H-profiles in dust grey

- Material: Anodised aluminium

- Alloy: EN AW 6063 T6

- Surface: Powder-coated

- Colour: Dusty grey (RAL 7037)

- Profile shape: H-profile (Connecting profile)

- Clamping range (max): 3,5mm, 6,5mm resp. 8,5mm

- Standard length: 2005mm

- Profile strength: 1,1mm

- Visible width: 17,0mm

- Profile width: 26,0mm

- Mounting surface: 12,45mm

- UV-resistance: Excellent

- Weather resistance: Excellent

- Corrosion resistance: Excellent

- Additional Information

Additional Information

Product-ID GPH-00 Standart Length 2000 Delivery Time Dispatch within 2-3 working days Material Aluminium anodised Profile type H-Profile Version 3mm - 8mm Color Grey Color accuracy Color similar to RAL color system RAL color code RAL 7037 Color designation Dusty grey - Reviews