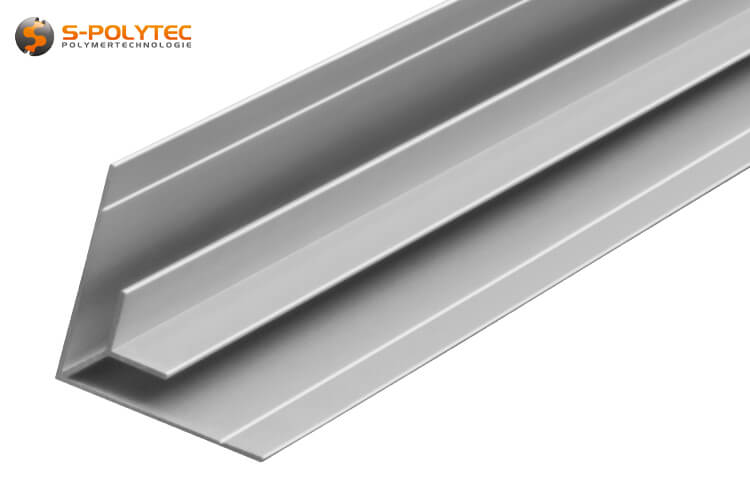

Aluminium inside corner profile silver (anodised)

Our silver anodised aluminium inner corner profiles are suitable as connecting profiles for slabs, tiles and floor coverings, which are arranged at right angles to each other. The profiles made of solid T6 aluminium are corrosion-resistant and can be used indoors and outdoors without hesitation.

✓ Solid EN AW 6063 T6

✓ Anodised surfaces

✓ High corrosion resistance

✓ For horizontal inside corners

✓ For vertical inside corners

✓ Even surfaces

The silver anodised inner corner profiles are available in 3mm, 6mm or 8mm clamping range at favourable graduated prices.

The item is in stock

Dispatch within 2 - 3 working days

- calculate the price

- at pieces 0,00 € (Base Price 0,00 € / m)

- at pieces 0,00 € (Base Price 0,00 € / m)

- at pieces 0,00 € (Base Price 0,00 € / m)

All prices include 19% VAT.

0,00 € / pc.

0,0000kg / pc.

All prices include 19% VAT.

- Description

Aluminium corner profiles in aluminium silver for inside corners

Anodised aluminium ✓ UV & weather resistant ✓ Smooth surfaces ✓

Our inner corner profiles made of anodised aluminium have a uniform silver-coloured surface and are made of solid aluminium with a profile thickness of 1.1mm. For the best possible protection against UV radiation and weathering, the profile surfaces are anodised using the so-called anodising process. The profiles for inside corners, which we stock with 3mm, 6mm and 8mm clamping range, are available in a standard length of 2 metres and are ideal as angle profiles for edge overlap which adjoin at right angles. The interior corner profiles are suitable for a wide range of applications, from interior and exterior wall cladding to wall and floor tiles, laminate and vinyl flooring.

The inner corner profiles are extremely bending-resistant, although the profile thickness is only 1 mm. The advantage of the low profile thickness is a very low weight that hardly needs to be taken into account when using vertical façade cladding. In addition, the protrusion from the aluminium profile to the surface of the panel, laminate or tile is so small that a visually homogeneous transition is created, which also makes cleaning much easier. The processing of the profiles, above all the sawing, is also much easier, even if the aluminium profiles are to be shortened with a hand hacksaw.

NOTE: With the inner corner profiles, we offer four different types of profiles for panel connection. These are all available in silver anodised finish as 2 metre standard lengths with 3mm, 6mm and 8mm clamping range and are therefore ideally suited for panels made from a wide range of materials and thicknesses.

Properties of the anodised inner corner profile

The optical profiles are mainly used for façade cladding with HPL, fibre cement or aluminium composite panels. Not surprisingly, we also use the colloquial architect's aluminium for the aluminium alloy. This is a very high-quality EN AW 6063 T6 aluminium, which is characterised by very good corrosion resistance, but which has been significantly improved by the anodic protective coating, so that the profiles can be used outdoors in all weather conditions without hesitation. However, the anodising process not only gives us improved weather resistance, but also results in a significantly better surface quality, which is uniformly silver and evenly smooth in direct comparison to untreated aluminium. The solid construction of our profiles, in combination with the high-quality alloy, creates a load-bearing corner profile for inside corners that has a very high inherent rigidity and increases the bending stiffness of the entire construction. This is particularly noticeable in thinner panels with low inherent rigidity or in free-standing constructions such as changing cubicles, sales and trade fair counters or partitioning systems in retail.

Our aluminium profiles are manufactured in accordance with the EN 12020 standard (extruded precision profiles made of EN AW-6060 and EN AW-6063 alloys) by our manufacturer in North Rhine-Westphalia. This manufacturer produces the inner corner profiles exactly according to our design drawings and guarantees a very high dimensional accuracy with very low manufacturing tolerances. The outer dimensions of the profile are always 40mm on both sides for all versions, which could also be used as a visible side if required. The visible inner side of the profile has a width of 10mm to both sides of the inner corner profile. Here too, the dimensions are identical, regardless of the clamping area. The only differences between the 3mm, 6mm and 8mm profiles are the clamping area and the width of the mounting surface. The anodised inner corner profiles with a 3 mm clamping area have a width of approx. 34 mm, which is the largest and results in a significant increase in the bending stiffness of the thin panels. The 6mm profile has an approx. 2mm smaller width of the mounting surface, which is again approx. 2mm smaller with the 8mm inner corner profile, resulting in a width of 30mm. The maximum clamping range is approx. 0.5mm higher for all three profile versions. This is due to the manufacturing tolerances of plastic panels, façade panels, as well as wall and floor coverings, which can sometimes be pronounced depending on the material and manufacturer. The slightly increased maximum clamping range ensures that the profiles can also be used for materials with higher thickness tolerances or structured surfaces. The surface quality of the silver anodised layer is also subject to strict quality controls so that we can always guarantee a consistently high quality for our aluminium profiles.

Specific data of the different profile sizes

- Alu corner profile for inside corners 3mm: Clamping range: max. 3.5mm, profile depth outside: 40.0mm, weight: 317g/m

- Alu corner profile for inside corners 6mm: Clamping range: max. 6.5mm, profile depth outside: 40.0mm, weight: 330g/m

- Alu corner profile for inside corners 8mm: Clamping range: max. 8.5mm, profile depth outside: 40.0mm, weight: 338g/m

Application and assembly of the silver aluminium corner profiles

The internal corner profiles made of aluminium are used to cover edges and are primarily used for interior and exterior wall cladding. Aluminium in the alloy AW 6063 T6 is corrosion-resistant, yet with our silver profiles we rely on a protective layer, which improves protection against weathering through anodic oxidation and at the same time results in a more appealing, uniform surface appearance. At best, the anodised profiles can be integrated during the installation of the cladding panels. In principle, it is also possible to push them onto the edges afterwards, provided there is sufficient space available, but if they are pushed onto one side of the cladding panels and the installation of the panels to the adjacent side takes place afterwards, the integration of the edge profiles for internal corners is made much easier. If the silver aluminium profiles are used for partition walls and room dividers, the same procedure is recommended, although additional gluing or screwing can be quite useful here.

TIP: We currently only offer the anodised inner corner profiles as whole profiles with a length of 2 metres. However, due to the low profile thickness of only 1 mm, they can be easily shortened to the desired size with a simple hand saw. This can be done effortlessly and much more precisely with a mitre saw.

If the profiles are used for skirting boards, stair treads or for the construction of shower back walls, they should be glued or drilled into the substrate at the desired position beforehand. You are well advised to use an MS polymer here, because this powerful assembly adhesive adheres to almost all substrates that are common in the construction sector. Such permanently elastic hybrid adhesives are also very suitable for bonding the profiles to the panel surfaces, ensuring not only a secure hold but also a corresponding expansion range. For this purpose, we have equipped the profiles with a fine groove within the mounting surface that improves adhesion during bonding, which has a particularly positive effect on very smooth surfaces. In addition, the position of the groove provides the ideal spacing for fastening with suitable screws without running the risk of the panels showing edge chipping under mechanical load. A standard drill for metal, such as our HSS-G drill in ground design, is sufficient for drilling the thin profiles.

Application examples of our profiles for inside corners made of aluminium

- The inner corner profiles are ideal for connecting HPL & acrylic glass panels for the construction of shower enclosures

- The profiles can be used for floor coverings as a connecting profile from the floor to the skirting board

- The silver inner corner profile is suitable for stair treads on which laminate or vinyl is laid

- The inside-corner profiles are also suitable for outside corners where the profile width is to be higher

- The inside corner profiles are ideal for changing rooms, partition walls and are also versatile for use in trade fair construction

Technical data of the aluminium corner profiles

- Material: Anodised aluminium

- Alloy: EN AW 6063 T6

- Surface: Silver anodised

- Colour: Aluminium silver

- Profile shape: Corner profile (inner corner profile)

- Clamping range (max): 3,5mm, 6,5mm resp. 8,5mm

- Standard length: 2005mm

- Profile strength Corner profile (inner corner profile: 1,1mm

- Visibility: 10,5mm

- Profile width: 40,0mm

- Mounting surface: 30,0mm-34,0mm

- UV-resistance: Sehr Excellent

- Weather resistance: Excellent

- Corrosion resistance: Excellent

- Additional Information

Additional Information

Product-ID SP-000 Standart Length 2000 Delivery Time Dispatch within 2 - 3 working days Material Aluminium (EN AW 6063 T6) Profile type Inside corner profile Version varies Color Metallic Color accuracy No information available Color designation Silver anodized - Reviews