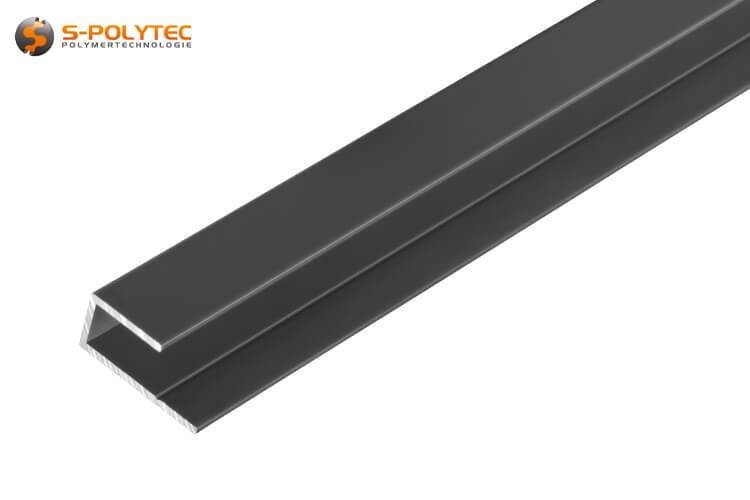

Aluminium U-profile anthracite (RAL 7016)

The aluminium U-profiles in anthracite are suitable as edge and end profiles for our aluminium composite and HPL panels in anthracite. The profiles made of corrosion-resistant AW 6063 alloy have a scratch-resistant powder coating with excellent UV and weather resistance.

✓ Powder coated in RAL 7016

✓ High quality EN AW 6063 T6

✓ UV- & weather resistant

✓ For indoors and outdoors

✓ High inherent rigidity

✓ Smooth surfaces

The anthracite grey edging profiles are available from us with 3mm, 6mm or 8mm clamping range at favourable graduated prices.

The item is in stock

Dispatch within 2-3 working days

- calculate the price

- at pieces 0,00 € (Base Price 0,00 € / m)

- at pieces 0,00 € (Base Price 0,00 € / m)

- at pieces 0,00 € (Base Price 0,00 € / m)

All prices include 19% VAT.

0,00 € / pc.

0,0000kg / pc.

All prices include 19% VAT.

- Description

Aluminium U-profiles in anthracite (RAL7016) as end profiles

Powder-coated surface ✓ For indoor & outdoor ✓ Corrosion-resistant ✓

Our aluminium U-profiles in anthracite (RAL 7016) are made of solid aluminium with a profile thickness of 1.1 mm. The anthracite grey profiles, which we offer with a clamping range of 3mm, 6mm or 8mm, are ideal as end profiles and are exactly matched in colour and gloss level to our HPL panels in RAL7016. They are therefore ideal for covering the edges of façade cladding and balcony surrounds with HPL and cover edge chipping as well as the dark brown core that is typical of HPL. In addition, the U-profiles can also be used in a wide variety of applications, from wall cladding, wall and floor tiles or even laminate and vinyl flooring as a finish. Due to the production from corrosion-resistant AW EN 6063 T6 aluminium and a UV and weather-resistant powder coating, the profiles can also be used outdoors without hesitation.

With a material thickness of 1.1 mm, our powder-coated end profiles are quite thin, but this is not at the expense of stability. The high inherent rigidity contributes to a significant improvement in the stability of constructions, especially with thin, flexible plastic panels. In addition to the high bending stiffness, the very low weight and the very easy machinability are also aspects worth mentioning. Especially as end profiles for façade cladding with HPL panels, the dead weight of the profiles hardly contributes to the overall face.

NOTE: Our U-profiles with powder coating in anthracite grey (RAL7016) are available in the standard length of 2000mm in versions with a clamping range of 3mm, 6mm or 8mm. In addition, we also carry H-profiles in 3mm, 6mm and 8mm with anthracite grey surface in 2 metre lengths at favourable prices.

Properties of the aluminium end profile in anthracite grey

Our profiles are exclusively made of high-quality EN AW 6063 T6 aluminium, which is characterised by excellent corrosion resistance. However, the U-profiles in anthracite grey are not anodised, but have a scratch-resistant powder coating in RAL 7016 with a gloss level of approx. 20%. Both the colour and the gloss level are exactly matched to our anthracite grey HPL panels in the cut. Even though the colour has no appreciable effect on the corrosion protection of the profiles, the powder coating contributes to an even, visually flawless surface and thus creates a transition from the panel surface to the profile that is as seamless as possible. The alloy, which is also casually referred to as architect's aluminium, is the first choice for construction profiles, which also include U-profiles, even if these are used more for visual than for structural reasons. Even in small thicknesses, the material is very robust and bending-resistant and thus improves the stability of constructions, for example in free-standing partitions or room dividers, for which HPL panels in anthracite, to which the powder-coated profiles perfectly match, are also very popular.

The clamping range of the profiles depends on the selection and is 3mm, 6mm or 8mm. The maximum clamping range is half a millimetre higher and ensures that panels with higher thickness tolerances can also be used. These variations can be more or less pronounced depending on the manufacturer and material.The material thickness of the profiles is always 1.1mm, regardless of the clamping range. This results in a profile depth of 5.7mm for the 3mm profile, which is calculated from twice the material thickness and the maximum clamping range of 3.5mm. For the 6mm U-profile, the total profile depth is 8.7mm. For the 8mm end profile, this dimension is 10.7mm. The production length of the powder-coated U-profiles is 2000mm (plus 5mm length tolerance) and the width is identical for all versions. The width is differentiated in the visible front side, which has a width of 12mm, and the rear side, which is also powder-coated. Here, the width is 20mm and has been deliberately chosen to be larger in order to allow the profiles to be optionally glued or screwed together. Since all our powder-coated profiles are coated on all sides, it is a matter of personal taste whether you use the wider back or the narrower front as the visible side of the profile. The production is carried out by our manufacturer based in North Rhine-Westphalia (Germany) under strict quality specifications in accordance with the EN 12020 standard (extruded precision profiles made of EN AW-6060 and EN AW-6063 alloys) and is checked both during and after production for compliance with the dimensional accuracy in order to be able to guarantee consistent first-class quality.

Specific data of the different profile sizes

- Alu U-Profile 3mm: Clamping range: max. 3.5mm, profile depth outside: 5.7mm, weight: 106g/m

- Alu U-Profile 6mm: Clamping range: max. 6.5mm, profile depth outside: 8.7mm, weight: 114g/m

- Alu U-Profile 8mm: Clamping range: max. 8.5mm, profile depth outside: 10.7mm, weight: 120g/m

Application and assembly of the aluminium U-profiles in anthracite

Our U-profiles with anthracite grey powder coating are exactly matched to the HPL panels in anthracite in terms of colour and gloss level, and so the profiles with 6 mm or 8 mm clamping range are consequently also very popular for covering edge chippings, inaccurate cuts or simply for visual reasons for façade cladding outdoors. Because the profiles are made of high-quality solid aluminium and the colour is UV and weather resistant, they can be used both indoors and outdoors. U-profiles are simply shortened to the required dimensions and then attached to the cut edges of the panels. With a mitre cut, these can also form a frame. Be it at the lower or upper edge corner, or deliberately as a frame for pictures, advertising signs, glazing or mirrors. The high-quality, silk-gloss lacquer finish of the profiles serves both as protection against sharp cut edges and to increase the bending stiffness. In addition, the profiles in anthracite also look extremely good and visually enhance partition walls, furniture or skirting boards.

TIP: With a standard length of 2000mm, our aluminium profiles are sufficient in length for most applications. In the event that they are needed shorter, cutting to size can easily be done with a simple hand saw with a fine metal saw blade. To avoid scratching the powder-coated surface when sawing, we recommend masking the desired area with a little masking tape.

Our profiles have a good clamping force for panels with a total thickness that corresponds to the specified clamping range. The production of façade panels, plastic panels or glass panels is subject to certain thickness tolerances, which can be more or less pronounced depending on the material and manufacturer. To ensure that the profiles can cope with such deviations and can be pushed on, the plus tolerance of 0.5 mm for the maximum clamping range is an important aspect. In individual cases, especially with very smooth surfaces, additional fixing of the grey end profiles can be helpful. Depending on the panel material, this can be done by bonding with a silicone or MS polymer, or by screwing with small screws. However, the profiles and the panels must then be drilled. A simple HSS drill is sufficient for this. To ensure that the screws are placed in a line and the adhesive and sealant can be applied in a straight line, the mounting surface of the U-profile has a filigree recess on the inside. On the one hand, this facilitates the application by applying the adhesive along this guide groove, but also contributes to an optimised durability of the bonding.

Application examples for aluminium U-profiles

- The aluminium U-profiles in anthracite are perfect for edging dark HPL panels or wall tiles

- The dark profiles create a beautiful contrast as a frame to light panels and backlit displays

- U-profiles in anthracite are very suitable for covering the edges of balcony surrounds, roofing and carports.

- The powder-coated profiles can be used as edge trims for partitions or skirting boards

- Aluminium U-profiles prevent cuts caused by sharp cutting edges of façade panels and tiles

Technical data of the aluminium U-profiles in anthracite

- Material: Anodised aluminium

- Alloy: EN AW 6063 T6

- Surface: Powder coated

- Colour: Anthracite grey (RAL 7016)

- Profile shape: U-Profile (End profile)

- Clamping range (max): 3,5mm, 6,5mm resp. 8,5mm

- Standard length: 2005mm

- Profile strength: 1,1mm

- Visibility: 12,0mm

- Profile width: 20,0mm

- Mounting surface: 19,0mm

- UV-resistance: Excellent

- Weather resistance: Excellent

- Corrosion resistance: Excellent

- Additional Information

Additional Information

Product-ID AL-UP-000P7016 Standart Length 2000 Delivery Time Dispatch within 2-3 working days Material Aluminium anodised Profile type H-Profile Version 3mm - 8mm Color Grey Color accuracy Production according to RAL color system RAL color code RAL 7016 Color designation Anthracite grey - Reviews

- Attachments