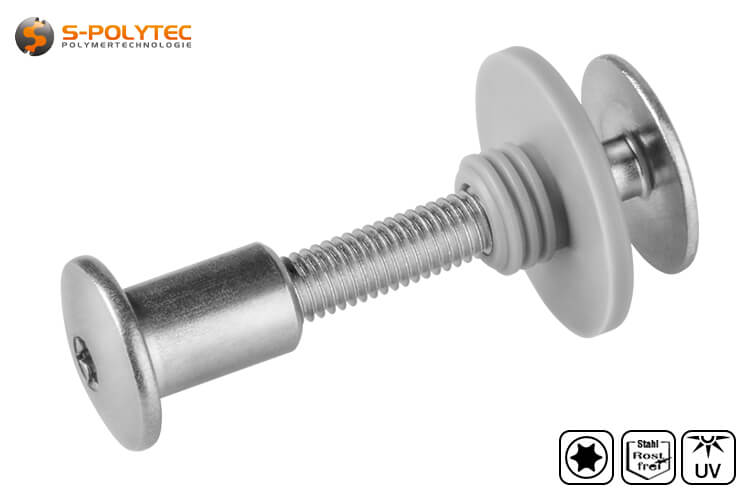

Balcony screw-set with threaded sleeve stainless steel (unpainted)

The balcony screw set with threaded sleeve made of stainless steel is ideal for balcony surrounds and cladding of stair railings with square profiles and consists of an unpainted balcony screw, a threaded sleeve and a vibration-damping spacer sleeve made of polyethylene.

✓ Stainless steel

✓ For indoors and outdoors

✓ Various lengths available

✓ With spacer sleeve made of LLD-PE

✓ Modern Torx-Drive

✓ Already from 1 piece

The unpainted balcony screw set with threaded sleeve is available in sizes M5x20mm to M5x50mm.

The item is in stock

Dispatch within 2-3 working days

- calculate the price

- from 10 Items €2.88/ pc. (Base Price €2.88/ pc.)

- from 20 Items €2.50/ pc. (Base Price €2.50/ pc.)

- from 50 Items €1.93/ pc. (Base Price €1.93/ pc.)

- from 100 Items €1.56/ pc. (Base Price €1.56/ pc.)

- from 200 Items €1.39/ pc. (Base Price €1.39/ pc.)

- from 300 Items €1.24/ pc. (Base Price €1.24/ pc.)

All prices include 19% VAT.

0,00 € / pc.

0,0000 kg / pc.

All prices include 19% VAT.

- Description

Balcony screws with threaded sleeve in stainless steel

Stainless A2 steel ✓ Unpainted finish ✓ From 1 piece ✓

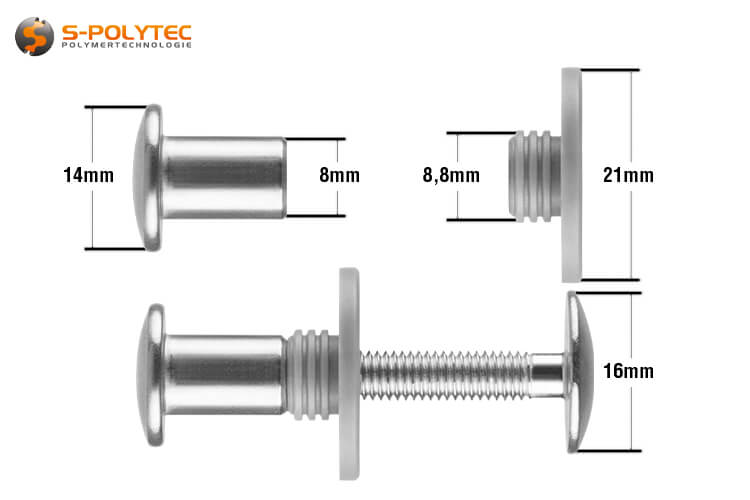

The balcony screw set with threaded sleeve, consists of a balcony screw, which we offer in various lengths, a polyethylene spacer washer and a threaded sleeve. Regardless of the screw length, the screw has a metric M5 thread and a head diameter of 12mm. The threaded sleeve, which has an internal thread of size M5, is slightly larger with a head diameter of 14mm. In the unpainted balcony screw set, the screw heads are bright and shine in the shiny, metallic silver typical of stainless steel. The modern hexagon socket drive (commonly known as TORX®) in size T20 is identical for both the screw and the sleeve and allows for a force-gentle screwing process in which no contact pressure has to be exerted on the screwing tool. As a fastener that is mainly used outdoors, we use a very high-quality A2 steel for the balcony screw and the threaded sleeve. This stainless steel is characterised by excellent corrosion resistance and enormous resilience.

NOTE: We offer the unpainted balcony screws in the sizes M5x20mm, M5x25mm, M5x30mm, M5x35mm, M5x40mm and M5x50mm. To determine the clamping range, 1mm to 5mm must be added to the thread length of the screw by using the threaded sleeve in each case.

Both the balcony screw and the threaded sleeve have a round, flat screw head with a hexagon socket. Two screwdrivers with an ISR20 (or Torx20) bit are therefore needed to work the screws. A spanner, as with the balcony screws with cap nut, is not required. A significant advantage of using the threaded sleeves is that the screw head, with a thickness of 2 mm, only protrudes insignificantly and, in contrast to the cap nut, is almost flush with the square profile.

Features of the balcony screw set with threaded sleeve in stainless steel

The unpainted balcony screw sets, consisting of a balcony screw with an M5 thread and a threaded sleeve with a corresponding internal thread, are, as the name suggests, assembly materials in which the screw heads are not painted. However, this in no way has a negative effect on the usability outdoors, because all our balcony and facade screws are made of stainless steel instead of cheap galvanised steel. The A2 steel alloy is characterised by very good corrosion resistance, which is also reflected in the costs for maintenance and servicing of an erected balcony cladding, privacy wall or stair guardrail. Because the security of a screw connection is of enormous importance, especially in such areas of application, all threaded sleeves are equipped with a 2-component adhesive that ensures a permanently strong screw lock that does not loosen even through sustained mechanical stress such as vibrations or impacts. This special thread locker contains the hardener component in tiny glass beads that break when the screw is screwed into the sleeve, resulting in chemical hardening.

While the other balcony screws are provided with a scratch-resistant head lacquer in the corresponding colour, which is also applied to the threaded sleeves depending on the selection, the balcony screw sets in the unlacquered version are always screws and sleeves that display the shiny silver colour typical of stainless steel. Due to the very high corrosion resistance, no additional galvanisation or clear coating is necessary.

For balcony cladding, privacy screens or stairways with HPL or aluminium composite panels, the panel should not be screwed directly to the substructure. For this reason, the balcony screw set also includes a spacer sleeve that is pressed into the hole of the square profile between the panel and the substructure. This inconspicuous grey sleeve is made of a high-quality LLD-PE, which is characterised by excellent sliding properties as well as a very high impact resistance. As a result, shocks and vibrations are absorbed in the best possible way and the thermal expansion of the panels is not impaired by an excessively high coefficient of friction.

NOTE: A2 stainless steel is an extremely corrosion-resistant steel alloy. Nevertheless, contact with aluminium can lead to corrosion resistance, which is why the use of the stainless steel balcony screws and threaded sleeves is only conditionally recommended for balcony and stair railings made of aluminium.

Use of balcony screws with threaded sleeve

The unlacquered balcony screws are extremely versatile, because in contrast to the head-lacquered screws, which are colour-coordinated with a specific surface of our HPL panels, the stainless steel-coloured screws can be combined with almost any surface decor without interfering. With Aluminium composite panels with brushed surface in silver Even a largely inconspicuous installation is possible. The PE spacer sleeve is inserted into the hole of the square profile on the side where the cladding panel is to be fitted later. The threaded sleeve is inserted on the opposite side. Before the screw can be screwed in, the panel must be stopped with the corresponding hole and the screws must be passed through this hole through the plastic sleeve. A second screwdriver with a Torx bit is necessary for screwing in the screw, because without fixing the threaded sleeve with it, the screw cannot be screwed in due to the thread adhesive for securing the screw. When installing, please always follow the instructions of the respective manufacturer of the balcony or stair railing, as well as the installation instructions of the panel manufacturer.

Due to the insertion depth of 12mm for the threaded sleeve and a further 5mm for the spacer sleeve, a minimum depth of 18mm is required for the square profile so that the two components can be fully inserted into the profile. The maximum thickness of the profile, on the other hand, is only limited by the length of the balcony screw. It should be noted that the 2mm thickness of the spacer washer as well as the panel thickness must be deducted from the clamping area. However, lower profile depths are not completely excluded, provided that the grey spacer sleeve is replaced by a simple washer made of slippery, vibration-damping material, for example our self-adhesive poly washers. In such cases, panel mounting is possible on balcony and stair railings with a profile thickness of 12mm and more.

In order to be able to insert the threaded sleeve or the spacer sleeve into the square profile, the latter must be drilled through if no holes have yet been drilled by the manufacturer of the balcony railing. For this purpose one HSS drill with 8,5mm diameter required. This drill can be used for both the steel and the plastic sleeve. It is important that the holes are drilled straight and in exactly the same position so that the screw can later be screwed into the internal thread without any problems. When drilling the hole inside the panel that is to be used for the balcony cladding, a distinction must be made according to the material. Aluminium composite panels are also best drilled with an HSS drill. For HPL panels a facade panel drill made of solid carbideis the better choice because it causes less edge chipping. The diameter of these holes should be 8.0mm for the sliding point fixings. On the other hand, for the fixed point, which is required for constraint-free mounting, the plate hole must be matched to the thread size of the screw with a diameter of 6.0mm.

The naming of the balcony screw set is due to its predominant use for the construction of balcony cladding. However, the unpainted screws and threaded sleeves are very versatile, regardless of whether they are used indoors or outdoors. An example would be the screwing of fence elements to square profiles made of stainless steel. The erection of a trailer structure made of MDF wood on steel profiles would be different. As with balcony surrounds, the profile must be drilled with an 8.5mm drill bit. Whether the polyethylene spacer sleeve is required or can be omitted always depends on the specific application.

General data of the balcony screw set

- Material: A2 stainless steel

- Head shape: Round, flat

- Drive: Torx 20 (T20, ISR20)

- Ø Thread: M5

- Tightening torque: 2-4 Nm

- UV-resistance: Excellent

- Corrosion resistance: Excellent

- Rust resistance: Excellent

- Acidity resistance: Well

Technical data of the balcony screw

- Colour: Stainless steel

- Length thread: 20mm, 25mm, 30mm, 35mm, 40mm or 50mm

- Ø Screwhead: 16mm

Technical data of the threaded sleeve

- Colour: Stainless steel

- Depth internal thread: approx. 12mm

- Ø Sleeve head: 14mm

- Ø Sleeve: 8mm

- Depth sleeve: 12mm

- Ø Drill: 8,5mm

Technical data of the spacer

- Colour: Light grey

- Material: LLD-PE (linear low density polyethylene)

- Ø Outer: 21,0mm

- Ø Inner: 5,5mm

- Ø Slat clamping: 8,8mm

- Thickness spacer: 2,0mm

- Thickness slat clamping: 5,0mm

- Ø Drill: 8,5mm

- Additional Information

Additional Information

Product-ID GW-unlackiert Delivery Time Dispatch within 2-3 working days Material Stainless steel A2 Screwsize No Screw drive Torx T20 Shape screwhead round Ø Screwhead 16mm (Sleeve 14mm) Type of thread Metric thread Ø Thread M5 Length screw thread varies Version varies Color accuracy No information available Color Metallic - Reviews