Seals made of PTFE - Made in Germany by S-Polytec

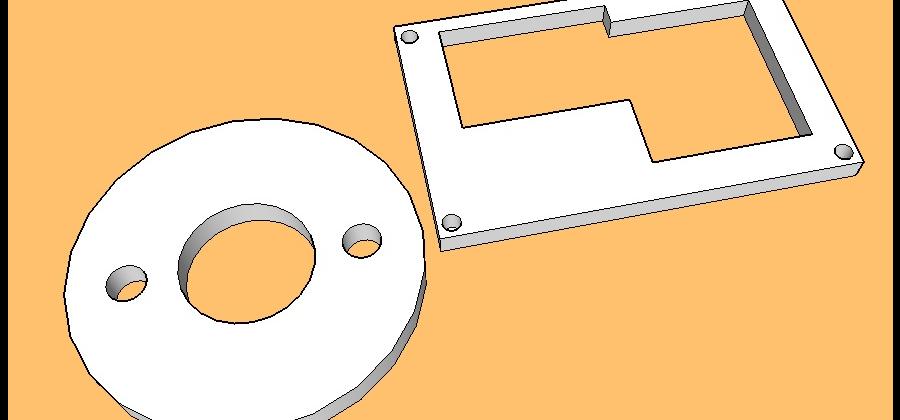

Seals made of PTFE. S-Polytec creates seals made of PTFE (polytetraflourethylene, Teflon©) according to your specifications - from prototypes to small runs to large quantities in series production.

Individual seals made of PTFE are used especially in the chemical industry. This is due to the fact that PTFE has excellent chemical resistance and very high temperature resistance of up to +260°C.

The production of PTFE seals can not only be very cost-intensive, depending on the type of production, but also involve long delivery times. With our milling service, we offer you the possibility of milling your PTFE seals exactly according to your specifications.

PTFE is a high-performance plastic that is characterised on the one hand by its very high temperature application range of -200 to +260°C. On the other hand, it has excellent resistance to chemicals and very good sliding properties. In addition, PTFE has excellent resistance to chemicals and very good sliding properties. For these reasons, polytetraflourethylene (also known under the brand name Teflon), is very often used as a sealing material, or as a sliding bearing.

Seals made of PTFE

Seals made of PTFE are not uncommon thanks to its many positive properties. For example, PTFE is used as a Teflon tape for sealing in the sanitary sector.

For the production of individual seals made of PTFE, for example for industrial plants or in appliance construction, special moulding tools are usually required which, on the one hand, can be very cost-intensive to produce and, on the other hand, become unusable in the event of minor deviations by the time a series-production tyre prototype is produced, since a new moulding tool has to be produced for every change to the prototype.

Advantages of S-Polytec PTFE seals

Individually milled seals offer you a lot of advantages. You don't need moulding tools, which can come with a very high initial investment. This means that the high tooling costs do not have to be amortised in later series production, so production is profitable from as little as one piece. Changes to the milling programmes can be made relatively easily and very quickly.

Seals made of PTFE in this way offer significantly more flexibility. This is especially true for systems that are manufactured in small quantities, such as chemical systems or special machinery.

Delivery time of the prototypes

Prototypes can be created quickly thanks to modern CNC milling technology.

For the production of seals made of PTFE as prototypes for series production, no complex moulding tools have to be produced thanks to our CNC milling service, so that the milling of the PTFE sheets can be carried out after very short lead times. This enables us to realise very short delivery times of only 2-3 days from order to delivery of the first prototypes.

Such fast production times are impossible when special manufacturing tools have to be created, as is the case with PTFE pressing, for example.

Another key advantage of milled PTFE seals is that adjustments to the prototype can be made easily without having to make new moulds, which also has a positive impact on cost efficiency and production time.

Series production is impossible when special moulds have to be made, as is the case with PTFE pressing.

Series production of PTFE seals

Once the prototype has been successfully used, it is also no problem for us to manufacture your PTFE seals in series. From small quantities at regular intervals, to the production of very large quantities, we are able to produce an exact reproduction of your PTFE gaskets based on the prototype.

Dimensions for milled PTFE seals

With our large area milling machines with vacuum tables, we can machine PTFE blocks in dimensions up to 4000mmx2000mmx100mm. The quantities here can vary from one-off production to large series. Send us your enquiry with a drawing or your design data. We will be happy to provide you with a free quotation for your individual seals made of PTFE.