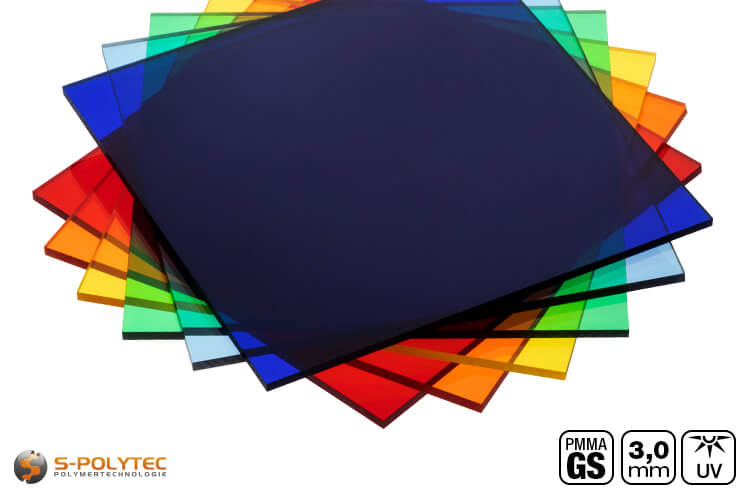

Coloured acrylic glass GS cut to size (transparent)

Our acrylic glass GS cut to size is available in many different colours. The acrylic sheets are transparent and coloured more or less intensively depending on the colour.

✓ Large colour range

✓ Uniformly coloured throughout

✓ UV- and weather resistant

✓ High ageing resistance

✓ Excellent surface finish

The colourful acrylic sheets in cast design are available in many colours with 3mm thickness cut to size.

The item is in stock

Dispatch within 2-3 working days

- Panels in Cut

- at pieces 0,00 € (Base Price 0,00 € / m2)

- at pieces 0,00 € (Base Price 0,00 € / m2)

- at pieces 0,00 € (Base Price 0,00 € / m2)

All prices include 19% VAT.

0,00 € / pc.

0,0000kg / pc.

All prices include 19% VAT.

- Description

Buy coloured acrylic glass GS cut to size online

UV- & Weather-resistant ✓ Large colour range ✓ Transparent tinted ✓

We offer the transparent sheets of coloured acrylic glass GS cut to size in many different colours with 3mm thickness at favourable prices. The solid acrylic sheets are transparent and have a light transmission of 8% (acrylic blue) to 84% (acrylic yellow) depending on the selected colour. Cast acrylic glass has a very high UV and weather resistance. Even with continuous outdoor use, the rich colours of the coloured sheets do not fade. The high pigmentation of the acrylic glass sheets results in a uniform colouring of the cut edges and surfaces. The very high surface quality for acrylic glass GS is reflected in high-gloss, even, mirror-smooth surfaces. To ensure that these are not damaged during further processing, the sheets are provided with a stable protective film on both sides, which protects the sheet surfaces from impacts and scratches.

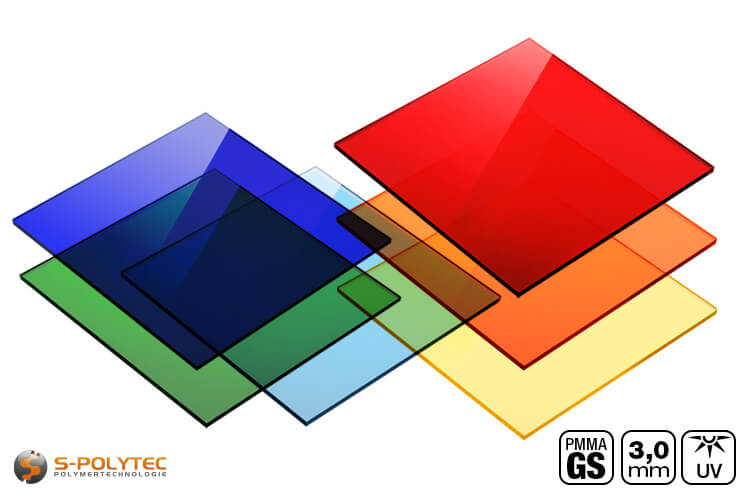

We offer the transparent acrylic glass sheets with tints in the colours red, orange, yellow, green, blue, light blue and blue in millimetre-precise cut to size at favourable prices. Cuts are possible from as little as 30mmx30mm. The maximum length of our blanks is 1500mm. The maximum width is 1000mm. Due to the saw cut, the edges are not polished, but saw-rough. As a specialist in cutting plastic sheets, we have many years of experience in sawing acrylic glass sheets and use special saw blades for the transparent plastics, which guarantee an even, precise cutting edge.

Properties of the coloured acrylic glass GS cut to size

The coloured sheets of acrylic glass GS are not extruded but cast. The basis for the coloured sheets is transparent acrylic glass, which is enriched with colour pigments. The more intense the colour is to be, the more colour pigments are added to the molten raw material before it is poured into a mould. The result is a homogeneous, evenly coloured plastic sheet with an excellent surface quality. The complex manufacturing process, which is particularly suitable for lower production volumes, contributes to the fact that acrylic glass is available in countless colours. By colouring, the light transmission of the otherwise crystal-clear, transparent sheet is reduced to a greater or lesser extent, depending on the colour saturation and brightness of the colour. Intense, dark colours therefore allow less light to pass through than light, weakly pronounced shades.

- Acrylic glass GS Red: Similar to RAL3020 (traffic red), light transmission approx. 13%

- Acrylic glass GS Orange: Similar to RAL2008 (Bright red orange), light transmission approx. 38%

- Acrylic glass GS Yellow: Similar to RAL1026 (Luminous yellow), light transmission approx. 84%

- Acrylic glass GS Green: Similar to RAL6037 (Pure green), light transmission approx. 61%

- Acrylic glass GS Blue: Similar to RAL5005 (Signal blue), light transmission approx. 8%

- Acrylic glass GS Light blue: Similar to RAL5024 (Pastel blue), light transmission approx. 64%

- Acrylic glass GS Grey: Similar RAL7016 (Anthracite grey), Light transmission approx. 24%

The typical properties of acrylic glass, such as very good UV and weather resistance, are not affected by the colouring, so that the red, green or blue sheets do not fade out outdoors even in strong sunlight and retain their strong colour. Acrylic glass GS is waterproof and enormously resistant to ageing. For this reason, the coloured acrylic glass sheets are very popular for outdoor advertising or for creating colourful garden decorations and light shows.

Application examples for coloured acrylic GS

Coloured acrylic glass is mainly used for decorative purposes, for furnishings or for lighting. From atmospheric lights for living room lighting to large-scale façade lettering consisting of illuminated letters and company logos for shops, discounters or commercial enterprises in bright red, blue, yellow or green. Coloured acrylic glass can also be used as a glass substitute.

Acrylic glass is very easy to work with and can be used to make costume jewellery or craft window or table decorations even without special knowledge. Red acrylic glass, for example, is excellent for tree decorations and window decorations at Christmas time. Green could be used for fir trees or at springtime. Yellow acrylic glass and orange acrylic glass are perfect for the autumn season and for Halloween decorations.

The transparent acrylic sheets are also popular for enhancing furniture. One example is the classic white shelves of a well-known Swedish furniture store. Here, the fronts and shelves can be easily transformed into a colourful piece of furniture by inserting, gluing or screwing in coloured acrylic glass panels. There are no limits to creativity when it comes to the colourful acrylic glass cuts.

- Coloured acrylic glass is used as a colour filter or for lighting in photography and videography

- Acrylic glass GS is used in event and media technology for colourful illumination of stages and dance floors

- Coloured acrylic glass GS is suitable for crafting table and window decorations for a wide variety of occasions

- Yellow acrylic GS reduces blue light waves and can thus significantly improve sleep quality

- For shower and cake back panels, the coloured acrylic glass panels are an eye-catcher with a high-quality look

- Grey acrylic glass GS is used as a glass substitute to reduce the amount of light with grey tinting

- and many more

Processing of cast acrylic sheets

Our cast acrylic glass can be processed in many different ways. The colour of the coloured, transparent sheets do not matter. From cutting, to bonding and gluing, to engraving or thermoforming, acrylic glass is an easy plastic to process.

Acrylic glass GS cutting and drilling

Acrylic glass is a brittle plastic that is much more impact-resistant than glass but can break if handled too roughly. Particularly when using cutting methods such as sawing, milling and drilling, care should therefore always be taken to ensure a firm base so that the acrylic sheet does not vibrate too much. While a circular saw is ideal for straight cuts, a jigsaw is well suited for cut-outs or curved cuts. The choice of saw blade is crucial here, because saw blades that are too coarse for soft woods will cause cracking and chipping at the cut edge. Saw blades that are too fine, as used for sawing metal, get hot too quickly, which causes the sawdust to melt at the cutting edge. A medium saw tooth size is the best choice here. To counteract heat build-up, the number of strokes should be significantly reduced.

Drilling acrylic glass is also a cutting method, and the same basic rules apply here. However, with a low speed and a firm base, drilling the hard, brittle boards is no problem. Commercially available HSS drills can be used. The quality of the drill hole is better with ground drills than with cheaper roll-rolled drills. With a plastic drills of type HK, the precision of the drilling can once again be significantly increased. These drills are specially designed for drilling brittle plastic sheets, which include acrylic and Plexiglas sheets. The very narrow point angle glides effortlessly through the hard surface. Thanks to the long, deep spiral groove, the plastic shavings are quickly conveyed out of the drill hole and thus do not heat up too much. The risk of the chip melting into the edge of the drill hole is thus considerably reduced.

In contrast to laser cutting, the edges appear slightly cloudy with machining techniques. This is also referred to as a saw-rough cut edge, which is noticeable by very fine grooves and scores. To polish the edge, the surface of the cut edge must be smoothed. Using fine sandpaper or a sanding block, the cut edge can first be freed from coarser irregularities. The finer the grit, the better the surface of the cut edge will be smoothed. To achieve a degree of gloss that approaches the surface gloss of the sheet, the cut edge must still be finished with an acrylic polishing paste and a polishing attachment for cordless screwdrivers. Flame polishing, in which the surface is heated with a cartridge gas burner until the cut edge appears smoothly polished, is another alternative, but the surface can quickly burn due to excessive heating. For this reason, flame polishing should only be carried out with the greatest care and attention.

Polishing the cut edge is not necessary with laser cutting. In contrast to sawing, laser cutting also offers the advantage that individual shapes with very filigree contours are possible. Another advantage of laser cutting compared to machining is that the engraving of the panel surface with a laser is much cleaner and therefore more visible. However, the protective film should be removed before laser processing so that it does not fuse with the cut edge.

Acrylic glass GS printing, lacquering and foiling

Printing on acrylic glass using the direct printing process is less common for coloured sheets because the colour tint distorts the print image considerably depending on the colour. In the case of very intense, strong colours such as red, blue or green, as well as grey-tinted acrylic sheets, the light transmission is also significantly reduced, so that the print, which is usually made on the back of the transparent sheet, is hardly perceptible.

A digital print laminated onto the front of the surface, on the other hand, is quite popular in advertising technology and can contribute to an exciting effect with backlit advertising and company signs, resulting in the print being coloured in the chosen colour. Similarly, lettering on company signs, product displays and notice boards can be used for almost any purpose for eye-catching, colourful advertising of companies and products due to the many colours available.

Glue and seal acrylic glass GS

Our acrylic glass can be excellently bonded with solvent-based adhesives. Especially when the colourful acrylic glass blanks are to be bonded together, we offer a solution with us Acrylic and plexiglass® gluePMMAprofi, a cold-welding adhesive that glues the acrylic glass sheets together almost invisibly. The very thin-bodied adhesive, with a viscosity similar to water, penetrates even the finest gaps due to its high capillary effect. The coloured acrylic glass is free of internal stresses due to the cast manufacturing process. Stress cracks on contact with solvents are therefore not to be feared, in contrast to extruded acrylic sheets.

If the coloured acrylic glass is to be bonded to or with another material, for example for the erection of an illuminated sign for outdoor use, our transparent Silicone sealant Parasilico PL a very good choice. The transparent MS polymer Parabond 600 is also a very good choice and impresses with its very high adhesion to almost all building materials.

Cleaning acrylic glass GS

Cast acrylic glass can be cleaned very well with a soft cloth and a little soap solution. However, only alcohol-free cleaning agents should be used on acrylic glass, as acrylic glass sheets are sensitive to contact with alcohols and solvents. In addition, do not use a microfibre cloth to clean or dry smooth surfaces, as these can leave fine scratches on the surface. With our acrylic and Plexiglas cleaner PMMAclean, we offer a gentle special cleaner that ensures thorough cleaning of acrylic glass and at the same time achieves a slightly antistatic effect so that the sheet surface attracts less dust.

NOTE: The coloured acrylic glass sheets are equipped with a protective film on both sides. Depending on the type of further processing, this must be removed beforehand. This includes, among other things, gluing, laser engraving or deep drawing.

- Additional Information

Additional Information

Product-ID 51000C Thickness 3 Delivery Time Dispatch within 2-3 working days Plastic Acrylglas Material PMMA Standard width 1500 Standart Length 1000 Fire behaviour Normal flammability UV resistance UV resistant Color No Color accuracy Color similar to RAL color system - Reviews

- Attachments

You may also be interested in the following product(s)

Acrylic adhesive - S-Polybond PMMAprofi 100ml

S-Polybond PMMAclean - Acrylic and plexiglass cleaner 500ml

S-Polybond PMMApolitur - Acrylic and plexiglas polishing paste 150ml

Spacer stainless steel 10x15mm screwable

Transparent acrylic glass GS cut to size (colourless)

Fluorescent acrylic GS cut to size (transparent)