Concrete base without drainage

Our heavy concrete bases made of solid concrete are used for the delay-free installation of our patio roofs and are suitable for all support posts where no drainage for rainwater is provided or possible.

✓ Cast from solid concrete

✓ Very high load-bearing capacity

✓ For posts without drainage

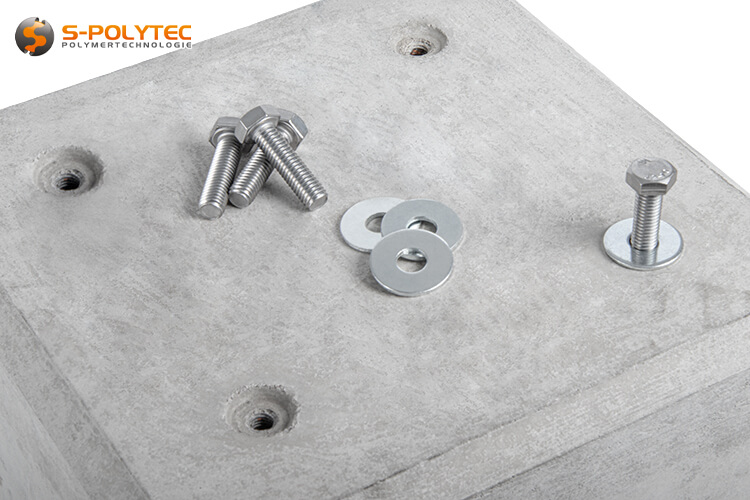

✓ Threaded sleeves moulded in

✓ Incl. matching screws

The threaded sleeves for mounting the support pillars of our patio roofs are already moulded in.

The item is in stock

Dispatch within 8-12 working weeks

- calculate the price

€77.00 / pc.

30,0000 kg / pc.

All prices include 19% VAT.

- Description

Concrete foundation for support posts without drainage

Incl. threaded sleeves ✓ Solid concrete ✓ Ideal for our patio roofs ✓

Our concrete base for simplified installation of our patio roofs is the best option for delay-free and safe installation. The size and weight of the solid concrete base is perfectly matched to the load exerted on the support posts by a patio roof and ensures sufficient load-bearing capacity and stability even in snowfall. The integrated M8 threaded sleeves, which are cast into the concrete, match the exact position and size of the fastening points of the base plates of the support posts of our patio roofs with polycarbonate or toughened safety glass roofing and, thanks to the screws and washers supplied, ensure smooth fastening.

In contrast to the concrete base with integrated drainage, the simple concrete base does not have a PVC pipe moulded in for drainage. For this reason, the simple base is suitable for all posts in which no downpipe for drainage is to be installed or is not possible due to the design. Alternatively, the drain can be sawn into the post with a hole saw. A hole diameter of 60 mm is required for our canopies.

NOTE: Due to its solid construction, the concrete base has a high dead weight for optimum stability of the support posts. However, at approx. 30kg, this is above the maximum weight for parcel shipping, which is why our prefabricated foundations can only be delivered by a forwarding agent.

Properties of the prefabricated concrete base for patio roofs

Our concrete bases as prefabricated foundations for our patio roofs are cast from solid concrete in a mould and are optimally matched to our patio roofs in terms of size, weight and load-bearing capacity, and guarantee a secure footing even under additional load from snow. A key aspect in favour of our ready-made concrete bases is the considerable time saving, because unlike a self-poured foundation, the support posts can be installed immediately after the bases have been placed, as they can be loaded immediately. If a self-poured concrete foundation is loaded too early, it can give way under the heavy weight and break. The same applies to concrete mixes where the mixing ratio has not been adhered to correctly or the components have not been mixed sufficiently, causing the concrete to crack, crumble or even break under load. These risks can be counteracted with a ready-mixed concrete base.

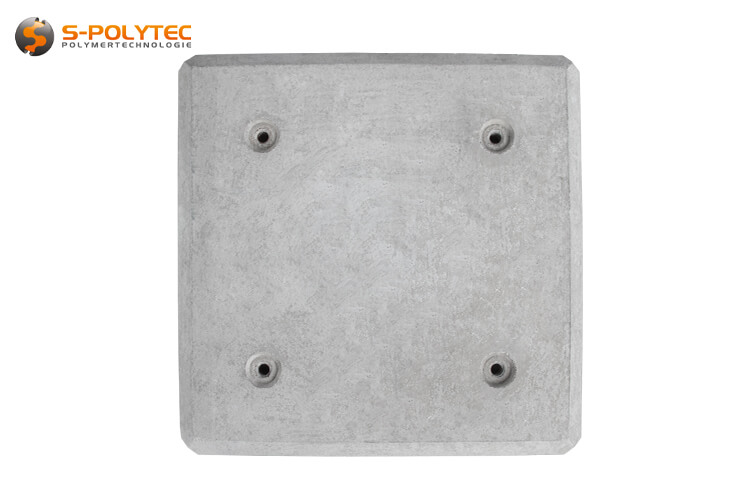

The dimensions of the concrete base are approx. 25cm for the length and width and 28cm for the height. However, the upper surface is slightly smaller at 23cm x 23cm. This means that the solid concrete block weighs around 30kg, which results in very good stability and stability against tipping even at the time of assembly and positioning of the support posts, when the base has not yet been dug in. The base area of 25 cmx25 cm is high enough to prevent it from sinking into the ground even under load and ensures good load distribution and compaction of the underlying soil. If the ground is too soft or unstable due to its natural properties, it is advisable to use an additional paving slab to increase the bearing surface.

To considerably simplify the installation of the patio roof, four threaded sleeves with an M8 internal thread and a thread depth of approx. 30 mm are embedded in the concrete on the upper side. The position with a hole spacing of 130 mm on each side is specially matched to the base plates of our patio roofs. The matching threaded screws and washers for screwing the base plate to the concrete base are included in the scope of delivery.

Handling the solid concrete base

With a prefabricated concrete base, there is no need to wait for a poured concrete foundation to harden. This saves time and the installation of the support posts for the patio roof can begin immediately. In most cases, it is desirable for the base to be completely embedded in the ground in order to ensure a continuous floor covering for the patio. This requires a hole of approx. 50 cm in width and length and a depth of approx. 35 cm. Please also take into account the thickness of any existing paving. The generous excavation is necessary to ensure sufficient clearance for the final alignment of the respective support posts using a spirit level. Before the base is embedded in the dug hole, loosened soil should be compacted and levelled using suitable tools. Otherwise, there is a risk of the plinth sinking or leaning over time.

TIP: A paving slab measuring 40x40cm or 50x50cm can increase the bearing surface of the concrete base. This is particularly recommended if the soil cannot be compacted sufficiently or if sufficient strength cannot be guaranteed due to the soil conditions. The use of a paving slab is particularly recommended in sandy, loose soil to prevent the base from sinking. It should be noted that the depth of the excavation must be adjusted by the thickness of the slab so that the plinth can be completely buried.

The size of the patio roof and the type of roofing define the number and position of the support posts. The distances between the individual posts, as well as the exact distance from the wall on which it is to be mounted, can be found in the installation instructions. These are available to download in several languages for the respective canopies and contain detailed, illustrated information on the installation and positioning of the support posts and the associated earthworks to embed the concrete bases in the ground. The top of the pedestals is very easy to recognise, as it has four threaded sleeves, which considerably simplify the installation of the support posts for our patio roofs. Thanks to the M8x30mm internal thread and the screws supplied, the base plate, which is screwed to the aluminium profile post, can be screwed together very easily and quickly. However, we recommend that you do not tighten the screws until the final strength is reached, as the final step in the assembly of the patio roof involves the final alignment of the posts using a spirit level.

NOTE: It is definitely advisable not to cover the base with earth immediately after installing the support posts, as the final step in the installation of our patio covers involves the final alignment of all posts using a spirit level. However, this step is no longer possible without problems once the concrete plinth and the screw connections of the base plate have been dug in.

Advantages of the concrete base

- The concrete base allows the patio roof to be installed without curing times for the foundation

- The load-bearing capacity of the concrete base is optimised for our patio roofing

- The base is suitable for all support posts for which no drainage is provided

- The integrated threaded sleeves allow easy installation of the post base plate

- The use of the plinth is not limited to the installation of our canopies

The concrete base for our canopies does not have to be used exclusively for installing our own patio canopies. Possible applications include the weighting and bracing of large tents and pavilions or free-standing advertising boards and banners. The base can also be used for patio roofs, carports and pergolas from other brands and manufacturers. It is important to check whether the positions of the threaded sleeves match. Even if this is not the case, this is not an obstacle, as holes for impact anchors or dowel fixings can be made in the concrete with a suitable hammer drill.

Technical data of the concrete foundation

- Material: Concrete

- Surface: Smooth

- Colour: Concrete grey

- Height: 28cm

- Bottom edge (W x D): 25cmx25cm

- Upper edge (W x D): 23cmx23cm

- Drill holes: Yes (with threaded sleeve)

- Drill hole spacing: 130mm

- Ø Drill holes: M8 Internal thread

- Screws: M8x30 (4x included)

- Drainage: No

- Total weight: approx. 30kg

- Additional Information

Additional Information

Product-ID BETON-OHNE Delivery Time Dispatch within 8-12 working weeks Material Solid concrete Property Concrete base without drainage Weight 30.0000 - Reviews