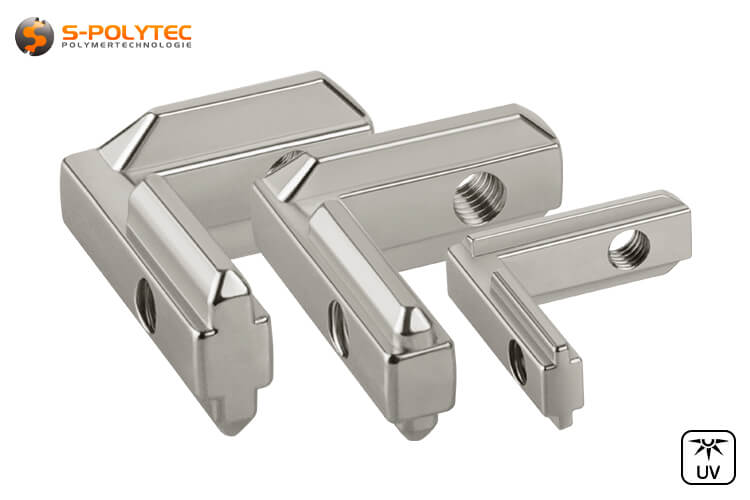

Corner connector for construction profiles (internal)

Our corner connectors for internal mounting of right-angled connections in construction profiles are made of nickel-plated zinc die-cast, are corrosion-resistant and suitable for structures that can be modified at any time, both indoors and outdoors.

✓ Rustproof die-cast zinc

✓ Grub screws included

✓ Internal mounting

✓ For inside and outside corners

✓ Flexible positioning

✓ Various sizes

The profile corner connectors for inner and outer corners are available in different sizes for 6mm or 8mm grooves.

The item is in stock

Dispatch within 2-3 working days

- calculate the price

- from 10 Items €1.55/ pc. (Base Price €1.55/ pc.)

- from 20 Items €1.50/ pc. (Base Price €1.50/ pc.)

- from 50 Items €1.45/ pc. (Base Price €1.45/ pc.)

All prices include 19% VAT.

0,00 € / pc.

0,0000 kg / pc.

All prices include 19% VAT.

- Description

Corner connector for inner and outer corners of construction profiles

Incl. grub screws ✓ Internal mounting ✓ 3 sizes available ✓

The corner connectors for connecting construction profiles at right angles are available in three versions corresponding to the sizes of our construction profiles. These can be used for both inner and outer corners when connecting construction profiles and are therefore ideal for basic constructions and frames or for reinforcing with cross profiles in larger constructions. The profile connectors can even be used with existing constructions, as well as with system profiles from other manufacturers. The only thing to pay attention to is the design of the groove width and depth to ensure that the corner connector can be inserted into the groove. The corner connection is completely internal due to the assembly process within the profile groove and the attachment with headless grub screws.

The solidly manufactured corner profile connectors contribute to a secure construction that is characterised by a high level of resistance to tensile loads or mechanical movement. Made of nickel-plated zinc die-cast, the corner connectors are extremely hard and highly corrosion-resistant. Even in damp environments, the risk of contact corrosion with aluminium is very low, even over the long term. The nickel-plated surface contributes to lasting resistance to corrosion and also creates a more appealing look, even if this plays only a minor role due to the hidden mounting in the profile.

Scope of delivery:

- 1 x inner corner connector made of die-cast zinc (in selected size)

- 2 x grub screws (M5 or M6)

NOTE: The internal corner connectors can also be used to attach groove profiles from other manufacturers. In this case, however, attention should be paid to the groove width and groove depth so that the connector can be easily inserted into the groove and screwed tight.

Properties of the internal corner connectors

The corner connectors are suitable for angle connections of inner corners and outer corners at a 90° angle for construction profiles in an identical profile design. The three different sizes available in our shop correspond to the construction profiles in terms of groove width and depth. This means that the small connector with a 6mm groove for the aluminium profile in 20x20mm groove 6, the medium connector with a lower connector thickness for the profile in 30x30mm groove 8 and the stronger connector for the 40mm construction profile can be used. The corner connectors can also be combined with other system profiles. However, attention must be paid to the groove width and depth, because these values are important for the connector to be inserted into the groove and fastened with the corresponding screws. A wide contact surface is used for high load capacities, which distributes the groove pull-out load over a wide area. To ensure a secure profile connection, the profiles are made of zinc die-cast, which is characterised by a high material hardness for optimal strength. The surfaces are nickel-plated. This achieves a very good corrosion resistance and thus allows for use in indoor as well as outdoor areas, without weather influences affecting the durability and appearance of the construction.

The internal corner connectors are screwed on with a grub screw on each side of the profiles. These are included in the scope of delivery so that assembly can begin immediately. The special feature of a grub screw is the headless screw drive with a continuous threaded area. This fastening solution makes it possible to integrate the connection completely within the profile. This is not only visually advantageous, but also means that the installation of furniture panels or cladding for a bicycle shelter in an outdoor area is not impeded by protruding screw heads. The length and thread diameter of the screws vary depending on the size of the corner connector.

Specific dimensions of the inner corner connectors

- inner and outer corner connector for 20x20mm groove 6 Dimensions: approx. 25.9x24.7mm, Slot depth: approx. 4.3mm, Slot width: 6mm, Ø Thread: M5, Weight: 10g (incl. grub screws)

- Inside/outside corner connector for 30x30mm groove 8 Dimensions: approx. 37.0x30.9mm, groove depth: approx. 7.3mm, groove width: 8mm, thread diameter: M6, weight: 32g (incl. grub screws)

- Inside/outside corner connector for 40x40mm groove 8Dimensions: approx. 37.0 x 30.9 mm, groove depth: approx. 8.3 mm, groove width: 8 mm, thread diameter: M6, weight: 38 g (incl. grub screws)

Mounting of construction profiles with corner connectors

The corner connectors are used inside the slot profiles. This means that the ends of the profiles must be freely accessible when the internal connectors are inserted. We recommend that you screw the grub screws a little way into the connector thread beforehand, as this makes tightening a little easier. Then insert the connector with the shorter side into the profile slot. When doing so, it is important to note the position at which the branching profile is to be attached and to ensure that the connector can be pushed to the desired position in the groove without being obstructed by other components. Finally, the second profile with the cross-section can be placed on the connector and everything can be screwed tight with an Inbus®- key.

Depending on your personal preference, the appearance of a visible construction can play a major role. It is for a reason that you decide on an internal corner connector that does not affect the appearance. To ensure that the profile, which is attached with the cut edge to the surface of the second profile, is flush, it should be sawn at a precise right angle and the edges deburred. Even though the aluminium profiles can be easily cut by hand with a hacksaw, we recommend using a crosscut and mitre saw for cutting. Or you can simply order the profiles cut to the millimetre using our cutting configurator.

TIP: The connectors are primarily intended for fixing construction profiles at a right angle. Yet, they can certainly also be used for other purposes. For example, to tighten cable tensioning systems through the hole for mounting, to fix objects with threaded screws in the thread of the corner connector or to fix cables for lighting with a cable tie.

The corner connectors are primarily intended for constructing right-angled profile connections for housings, racks or frames. They ensure a secure and firm screw connection. Furthermore, the internal connecting pieces can be freely positioned within the profile groove. This means that they can be used to brace larger constructions or to reinforce profile frames that are subject to higher loads due to weight or mechanical stress. The fact that the connectors can be loosened and moved in the groove at any time makes modular and variable shelving systems possible, which can be adapted to changing circumstances at any time. However, it is not necessary to screw another profile to the connectors. The internal thread of the protruding element can also be used to stretch wires or ropes. One possible application would be an almost invisible climbing aid consisting of a nylon rope for climbing plants, such as ivy or monstera. If the structures are used in furniture construction, supply lines for lights, LED strips laid in the groove or charging cables for smartphones could also be attached to the corner connector with a cable tie to provide secure strain relief. Basically, the only limits to their use and misuse are your own imagination and creativity when implementing DIY projects.

Examples of how our internal- & and external corner connectors can be used

- The corner connectors can be used to construct shelving systems with variable shelf heights

- The internal mounting allows for an invisible corner connection of the construction profiles

- For higher loads, internal connectors can be combined with mounting brackets

- The concealed installation means that it can be covered with plastic or wooden panels without restriction

- The filigree corner connectors are ideal for tensioning wires, ropes and cords, e.g. as a climbing aid

Technical data for corner connectors for construction profiles

- Material: Zinc die casting (stainless)

- Colour: Silver

- Edition: 20x20 groove 6, 30x30 groove 8 or 40x40 groove 8

- Mounting type: Internal

- Total length: Approx. 25.9 mm or 37.0 mm

- Total height: Approx. 24.7 mm or 30.9 mm

- Insertion height: Approx. 4.3mm, 7.3mm or 8.3mm

- Groove width: Groove 6 or Groove 8

- Number of holes: 2

- Ø Thread: M5 resp. M6

- Screw: Grub screws (included)

- Weight: Approx. 10g, 32g or 38g (incl. grub screws)

- UV-resistance Excellent

- Weather resistance: Excellent

- Corrosion resistance: Excellent

- Additional Information

Additional Information

Product-ID EKV-0000 Delivery Time Dispatch within 2-3 working days Property Corner connectors for construction profiles (internal) Material Nickel-plated die-cast zinc Color Silver - Reviews

You may also be interested in the following product(s)

Aluminium construction profile 20x20, groove 6 silver (anodised)

Aluminium construction profile 30x30, groove 8 silver (anodised)

Aluminium construction profile 40x40, groove 8, silver (anodised)

90° angle bracket for construction profiles

Profile connectors for construction profiles

Profile connector with adjustable angle