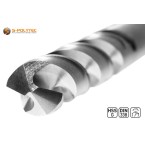

HSS-G Countersink Set 90° (6 pieces)

The 6-piece taper and countersink set made of HSS steel in profile-ground design is suitable for deburring and chamfering hole bores and is also perfect for countersinking holes for countersunk screws in sizes from M3 to M10 according to DIN 963 and 965.

✓ In metal transport box

✓ For countersunk screws to DIN 963

✓ High-quality HSS steel

✓ Profile-ground design

✓ Very long service life

✓ TOP Quality

The HSS-G countersinks are equally suitable for metals and plastics.

The item is in stock

Dispatch within 2-3 working days

- calculate the price

€49.90 / pc.

0,5000 kg / pc.

All prices include 19% VAT.

- Description

HSS-G taper and deburring countersink as set in industrial cassette

Profile-ground design ✓ TOP Quality ✓ In industrial cassette ✓

The high-quality taper and deburring countersink set from Bohrcraft consists of 6 individual taper countersinks in different diameters, starting at 6.3mm up to 20.5mm, in a handy transport box made of robust metal. The countersinks with a countersinking angle of 90 degrees are made of durable high-speed steel (HSS-G). For maximum precision, the cutting edges are profile ground so that deburring or chamfering of drill holes can be carried out without effort, even with hard materials such as most metals or brittle plastics such as acrylic glass or Plexiglas. The countersinking of countersunk screws according to DIN 963 or DIN 965 is also done in no time with our professional countersink set. The set includes the most common sizes for threaded screws with countersunk head in sizes M3 to M10.

All countersinks have a type C 90 countersink angle with a right angle of 90 degrees according to DIN 335 and each has three very sharp, profile-ground cutting edges with generously dimensioned flutes that cleanly remove the burr and contribute to reduced heat development. The overall length and the point diameter, on the other hand, vary depending on the overall diameter of the respective countersink. Detailed information on the technical dimensions of the individual countersinks can be found in a separate list below. Due to the precision-ground cutting edges, care should be taken when removing and clamping the countersink drills so as not to injure yourself on the cutting edges.

The 6-piece set is supplied in a practical metal industrial case. This means that the countersinks are always ready to hand and can be safely stowed away again before or after use, effectively preventing damage to the sharp cutting edges of the countersinks during transport caused by drills and tools flying around in the toolbox.

-

Scope of delivery:

- 1 x HSS-G taper and deburring countersink set 6 pcs. in industrial case

NOTE: Always store the countersinks in the industrial cassette to avoid damage to the cutting edges during transport. Countersinks with bumps on the cutting edges should not be used any longer, as they can jam, which can have a detrimental effect on the drilling result.

Technical data of our HSS-G countersinks

- Ø Countersink: 6,3mm - 20,5mm

- Ø Tip: 1,5mm - 3,5mm

- Ø Shaft: 4,0mm - 10,0mm

- Number of blades: 3

- Standard: DIN 335

- Record: Cylindrical adhesion

- Direction of rotation: Clockwise

- Material: High-speed steel (HSS)

- Countersink angle: 90°

- Reduction: M3 - M10 according to DIN 963 and DIN 965

- Ground: Profile ground

- Type: 90C°

Use of taper and deburring cores made of HSS steel

Taper and deburring countersinks are suitable for deburring the edges of drilled holes in plastic, hardwood and many metals. The taper countersink is clamped in a cordless screwdriver or handle with chuck and placed vertically on the drill hole. If only the burr is to be removed from the drill hole, a slight turn is usually sufficient. If, on the other hand, the hole is to be chamfered, the tool must be used by turning it clockwise until the chamfer has reached the desired thickness.

In order to be able to screw in countersunk screws so far that the screw head is flush with the material surface, it is advisable to countersink with a suitable countersink. If a countersink is not used, or if it is not sufficiently large, the countersunk screw can be screwed in too deep and cause a crack at the edge of the drill hole. This occurs especially with decking made of wood or WPC, or also with plastics with a high degree of brittleness such as acrylic glass or rigid PVC, where an excessively high tightening torque can result in the panel breaking. Our taper countersinks are ideal for countersunk screws with metric threads that were manufactured according to DIN 963 or DIN 965, because the diameter of the respective countersink corresponds exactly in size to the required diameter for a complete, precise countersinking of the corresponding countersunk screw.

In order to achieve even round chamfers and countersinks of the holes, it is very important to select a very low speed and not to exert any pressure on the countersink, otherwise the cutting edges may jam on the edge of the hole. As the hardness or brittleness of the material increases, the speed should be reduced further to counteract excessive heat development, which can result in annealing of the cutting surfaces. Additional cooling with a drilling paste or cutting oil can also significantly extend the already very long service life. Additional cooling is particularly recommended for continuous countersinking and hard metals such as iron, copper or non-alloy steels.

TIP: Thanks to the infinitely variable cutting edges of the countersinks, the countersinks with larger diameters can also be used without hesitation for countersinking holes for countersunk screws with smaller head diameters, instead of always having to replace the countersink.

Dimensions of the individual countersinks in detail

- Countersink 6,3mm: Ø Tip 1,5mm - Ø Shaft 4,0mm - Total length 45mm - M3 Reduction DIN 963 or 965

- Countersink 8,3mm: Ø Tip 2,0mm - Ø Shaft 5,0mm – Total length 50mm - M4 Reduction DIN 963 or 965

- Countersink 10,4mm: Ø Tip 2,5mm - Ø Shaft 6,0mm - Total length 50mm - M5 Reduction DIN 963 or 965

- Countersink 12,4mm: Ø Tip 2,8mm - Ø Shaft 8,0mm - Total length 56mm - M6 Reduction DIN 963 or 965

- Countersink 16,5mm: Ø Tip 3,2mm - Ø Shaft 10,0mm - Total length 60mm - M8 Reduction DIN 963 or 965

- Countersink 20,5mm: Ø Tip 3,5mm - Ø Shaft 10,0mm - Total length 63mm - M10 Reduction DIN 963 or 965

Application examples for deburring and taper countersinks

Countersinks are perfect for deburring holes and are therefore often called deburring countersinks. Particularly when drilling in metal and plastic, drilling usually produces a very fine, sharp-edged burr on the edges of the drill hole, but with a deburring countersink this can be removed in no time at all. As a rule, a single turn is sufficient to remove the burr completely. This is made possible by the three sharp cutting edges that are arranged at an angle of 120 degrees to each other. If the drill hole is also to have a small 45 degree chamfer, further turns are necessary depending on the thickness of the chamfer, whereby the cutting edges remove the material evenly along the edges of the drill hole until the desired depth of the chamfer is reached.

In furniture making, cupboards, shelves and tables are very often screwed with countersunk screws in order not to have any annoying, protruding screw heads on the side panels and shelves. While with solid hardwood it is hardly possible to countersink the screw head flat without countersinking the drill hole and the screw tends to break off at the head, especially soft woods such as pine or spruce tend to crack and, depending on how close the hole is positioned to the edge of the board, this can also result in the wood splitting in the course of the grain. By countersinking the drill holes, the risk is considerably reduced, so that a secure screw connection is possible without protruding screw heads, which can later be perfectly concealed with screw head covers made of plastic.

A similar problem occurs when laying decking boards made of solid wood or WPC (Wood Polymer Composite), provided they are screwed directly to the substructure and not mounted indirectly on the substructure via small spacers. Here, too, the hardness of the flooring plays a decisive role and provides information as to whether a missing drill hole countersink will cause the planks to split or the screw head to tear off. For garden fences, wooden cladding of tool sheds or carports that are to be erected with wooden boards, it also applies that for countersunk screws, the prior chamfering of the drill hole leads to optimal results, which ultimately also has an effect on a better appearance.

Screwing heavy metal plates with countersunk screws has the decisive advantage that the plates no longer shift in the vertical position due to the high dead weight, as can be the case with cylindrical screws or flat-head screws if the hole drillings are not adapted exactly to the diameter of the screw thread. Countersinking the countersunk head in the countersink creates an additional hold and also allows no interfering screw heads to protrude. Without first countersinking the drill hole, it is impossible to screw in the screw deep enough without the screw head drive stripping or the screw head breaking off. However, when deburring, chamfering and countersinking holes in metal of any kind, care should be taken with personal protective equipment, as the metal chips removed can be very sharp-edged, creating an increased risk of injury. Protective gloves and suitable safety goggles are therefore strongly advisable.

WARNING: Countersinks should never be used with the percussion drilling function activated, otherwise the cutting edges of the countersinks can be damaged, making them unusable in the worst case.

- Additional Information

Additional Information

Product-ID IK-KS6-HSSG Delivery Time Dispatch within 2-3 working days EAN/GTIN 4014691601084 Material High speed steel (HSS) Drill size No Ø Bore 6,3mm - 20,5mm Ø Schaft 4,0mm - 10mm Take-up Shank Straight shank Overall length various Spiral length various Spiral type C 90° Point angle 90° Direction of rotation Clockwise Weight 0.5000 - Reviews