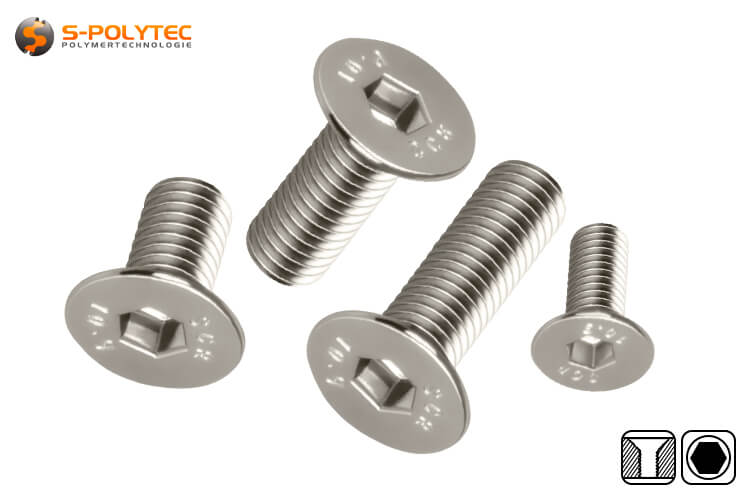

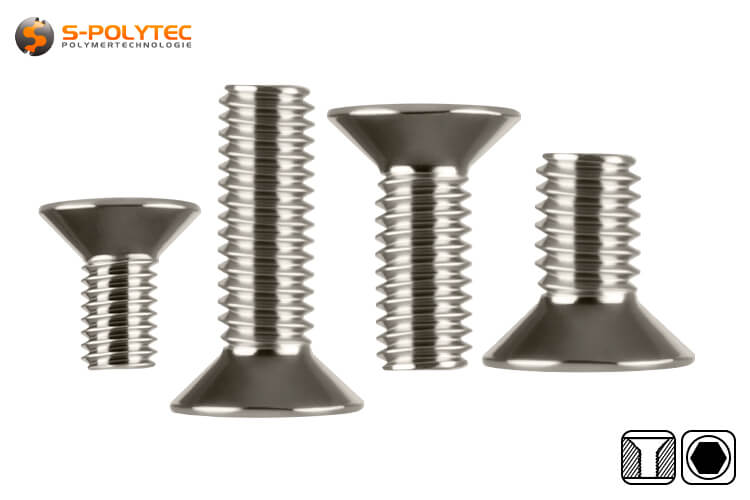

Countersunk head screw made of carbon steel (nickel-plated)

The countersunk head screws with a conical screw head and internal hexagon drive are suitable for all kinds of flush-mounted installations, both indoors and outdoors. Thanks to the nickel-plated carbon steel, the screws are protected against corrosion and have an attractive surface finish.

✓ Made of carbon steel

✓ With nickel coating

✓ With internal hexagon drive

✓ 90° countersunk head according to DIN 7991

✓ Various sizes

✓ Very high strength

✓ For indoor and outdoor use

The countersunk head screws according to DIN 7991 are available in the thread diameters M4, M5, M6 and M8.

The item is in stock

Dispatch within 2-3 working days

- calculate the price

- from 50 Items €0.06/ pc. (Base Price €0.06/ pc.)

- from 100 Items €0.05/ pc. (Base Price €0.05/ pc.)

- from 200 Items €0.04/ pc. (Base Price €0.04/ pc.)

All prices include 19% VAT.

0,00 € / pc.

0,0000 kg / pc.

All prices include 19% VAT.

- Description

Countersunk head screw made of carbon steel, in accordance with DIN 7991

With nickel plating ✓ Hexagon socket drive ✓ 90 degree countersunk head ✓

Our countersunk head screws made of nickel-plated steel with M5, M6 or M8 thread are available in lengths from 10mm to 20mm, depending on the thread diameter, and have a hexagon socket drive. The conical head of the threaded screw is used for flush mounting and is ideal for all applications where a protruding screw head is perceived as disturbing for visual or technical reasons. The nickel coating not only provides effective protection against corrosion when used in corrosive environments or outdoors, but also gives the screws an attractive surface finish. This makes the finely polished screws an excellent choice even for applications with the highest demands on appearance.

Countersunk head screws are manufactured in accordance with DIN 7991. Typical of this type of threaded screw is the large conical head, which has an angle of 90 degrees. This results in a very large contact surface, which serves for optimal load distribution, even at high mechanical loads. The internal hexagon drive is also designed to achieve high tightening torques with little effort. Unlike cross-head or slot screws, there is no risk of damaging the drive in the process.

NOTE: When installed correctly, a countersunk head screw is flush with the surface. Therefore, it is common to specify the length of the screw in such a way that the measurement refers to the total length of the screw. The actual thread length is thus shorter and is calculated from the screw length minus the height of the conical screw head.

Properties of our nickel-plated countersunk head screws

Countersunk flat head screws are also referred to as flat head screws because the head is flush with the surface after installation, contributing to a homogeneous, attractive overall appearance of the fastening. The angle, as seen from the thread, corresponds to a right angle, which is typical for screws manufactured according to DIN 7991. The large, round head has a hexagon socket drive. The outer diameter of the screw head is twice the value of the thread diameter. Thus, it is significantly larger than for a cylinder screw with the same thread diameter, ranging from 8mm for the M4 threaded screw to 16mm for a screw with M8 thread. The thread itself is metric, so that the screws can be screwed into all standard nuts, threaded sleeves or fixed threads of the same size to create a screw connection that is permanently secure and resilient.

Our countersunk head screws with internal hexagon drive are made of nickel-plated carbon steel. This is a steel alloy characterised by very high strength and toughness, resulting in higher load-bearing capacity and resistance to mechanical stress. Ideal conditions for screw connections that are subject to high loads. The nickel coating protects the carbon steel from rust and corrosion, which extends the lifespan of the products, especially in humid or aggressive environments. This makes our countersunk head screws equally suitable for indoor and outdoor fastenings. In addition, the nickel-plated surface offers additional protection against chemical reactions, which is highly important in certain industrial applications. It also contributes to an attractive appearance with a glossy finish. All of this makes nickel-plated carbon steel a popular choice for many industrial and commercial applications. From the automotive industry to mechanical engineering or the construction industry, right up to furniture making, the coated metal is one of the most popular materials with the perfect properties in terms of durability and price.

Unlike stainless steel, the nickel surface coating is better tolerated in contact with aluminium, as the risk of contact corrosion between these two metal alloys is significantly reduced. This makes the countersunk head screws perfect for our construction profiles. In particular, in combination with simple slot nuts or slot nuts with spring balls, variable constructions can be realised in just a few seconds, which can be adapted to suit your needs at any time. In particular, the hinges made of plastic or die-cast zinc, or the 90-degree angles, can be attached to the slot of the profile in this way at any time. The necessary countersinks for flush mounting are already provided in these attachments.

Specific data of countersunk screws with internal hexagon

- M4 countersunk head screw: Ø Thread: 4mm, Ø head: 8mm, height of head: 3.0mm, drive: HEX 2.5

- M5 countersunk head screw: Ø Thread: 5mm, Ø head: 10mm, height of head: 3.3mm, drive: HEX 3

- M6 countersunk head screw: Ø Thread: 6mm, Ø head: 12mm, height of head: 4.0mm, drive: HEX 4

- M8 countersunk head screw: Ø Thread: 8mm, Ø head: 16mm, height of head: 5.0mm, drive: HEX 5

Installation and use of countersunk head screws

The countersunk head screws made of carbon steel have a metric fine thread that cannot be screwed directly into the material, but requires an internal thread as a counterpart into which the thread is screwed. This can be done using a hex nut, a flange nut, a cap nut or a threaded sleeve. In metal construction, especially for structures made of rectangular hollow sections, the thread for receiving the screw can also be cut directly into the metal. In furniture construction, drive-in nuts with internal threads are also very common. These are driven into a milled groove in the surface of the board. Sharp steel cramps hold the drive-in nut securely and firmly in the wood-based material.

To use the screws, a socket wrench with a T-handle and a hexagonal drive or an Allen® key is required. A cordless screwdriver with the appropriate bit insert will do the same job. The size of the bit depends on the size of the screw and varies from 2.5 mm for the small M4 screw to 5 mm for a screw with an M8 thread.

NOTE: To use countersunk head screws, a depression is required in the surface of the mounting object so that the screw is flush with the surface and sufficient load distribution is ensured on the conical surface of the screw head. However, such depressions are very easy to make using a standard countersink, for example our six-piece HSS-G countersink and deburring set 90°.

Countersunk head screws are also an almost indispensable fastening element for our construction profiles and are mainly used for angles or hinges that have a depression to ensure a flush surface finish. This is particularly important for hinges, because if the screw head protrudes, the hinge can no longer be closed completely. This makes its function redundant. Installation is usually done with sliding blocks that are inserted into the slot of the construction profile and have an internal thread. Sliding blocks are available in different versions for different slot widths, slot depths and thread sizes and have the great advantage that they can be inserted into the profile, moved or removed again at any time. The slot nut should, of course, be matched to the diameter of the countersunk screw. When selecting the countersunk head screw, care should also be taken to ensure that the thread is not too long, so that the screw can be fully screwed in without the risk of it being prevented by an insufficient slot depth.

Countersunk head screws are often used in furniture construction to connect furniture parts such as tabletops, chairs and shelves, as they provide a smooth surface and the screw heads do not protrude. Flat head screws with conical heads are also used in the automotive industry. Here, they are used to fasten interior panels, dashboards and other parts where flush mounting is required. The same applies to mechanical and apparatus engineering, where components and housing parts need to be securely connected without the screw head protruding. This makes it possible to construct in a smaller space, where the individual devices are set up close together, without any space being created by protruding screw heads. A secure connection without screws protruding is just as helpful in production plants for series production in industrial manufacturing as it is in the large-scale kitchen in catering establishments, the fitted kitchen at home or a generous bookcase in the living room or office.

Examples of applications for countersunk head screws made of carbon steel

- Countersunk screws are ideal for flush screw connections of cabinet carcasses and shelves

- Countersunk screws ensure that hinges with a countersunk hole can be closed completely

- Countersunk head screws are used for the housings of built-in kitchen appliances, microwaves or washing machines

- The screws are perfect for constructing table frames without protruding screw heads

- Countersunk head screws made of steel are used in staircase construction to mount the handrail to the banister

Technical data for countersunk head screws

- Material: Carbon steel (nickel plated)

- Colour: Silver

- Headshape: Round, conical

- Countersunk head screws: 90 Degrees

- Drive: Hexagon socket (HEX, Inbus®)

- Ø Thread: M4, M5, M6 or M8

- Length thread: 10mm to 20mm

- Ø Head: 8mm to 16mm

- Depth head: 3.0mm to 5.0mm

- Weight: 1g to 8g

- UV-resistance: Excellent

- Weather resistance: Excellent

- Corrosion resistance: Sufficient

- Additional Information

Additional Information

Product-ID SES-0000 Delivery Time Dispatch within 2-3 working days Material Carbon steel (nickel plated) Screwsize No Screw drive varies Shape screwhead round Ø Screwhead 8mm - 16mm Type of thread No Ø Thread M4, M5, M6 oder M8 Length screw thread 10mm - 20mm Color accuracy No information available Color Silver - Reviews