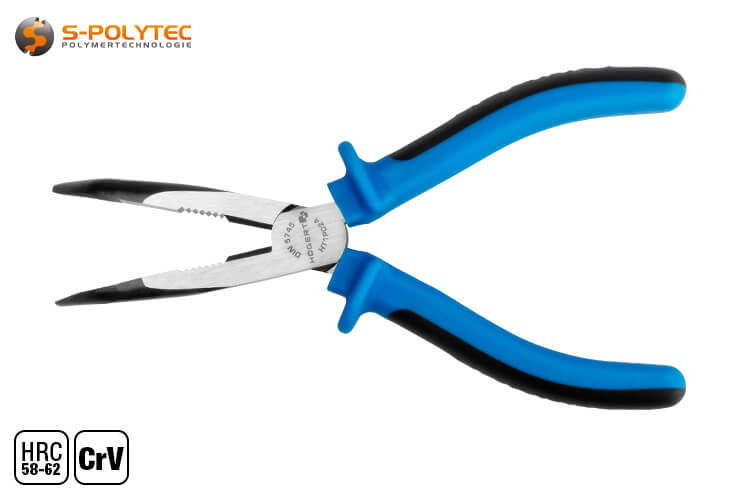

Round nose pliers, curved (DIN 5745)

Our curved round nose pliers with a tapered tip made from chrome vanadium steel with an arc angle of approx. 40 degrees are ideal for precision work. The larger pliers also have a straight burner hole with coarse teeth.

✓ Tapered tip

✓ 40° curved flat round tip

✓ Lateral cutting edge with bevelled edge

✓ High-quality chrome vanadium steel

✓ Two-component handle

✓ Ergonomically shaped

The high-quality round nose pliers with a curved tip are available in lengths of 160 mm or 200 mm.

The item is in stock

Dispatch within 2 - 3 working days

- calculate the price

0,00 € / pc.

0,0000 kg / pc.

All prices include 19% VAT.

- Description

Högert round nose pliers with curved tip

Chrome vanadium steel ✓ Inserted joint ✓ According to DIN 5745 ✓

Our curved flat nose pliers from Högert are combination needle nose pliers with elongated, flat jaws and a lateral wedge cutting edge and are available in either 160mm or 200mm overall length at favourable prices. The high-quality pliers in workshop quality are made of chrome vanadium steel. The tapered tip with an arc angle of approx. 40 degrees is ideal for precise work in hard-to-reach places. The larger pliers also have a straight burner hole with coarse teeth. The flat jaws, on the other hand, are very finely serrated for precise gripping with a reliable hold, even with very fine wires and wafer-thin objects. The very good workmanship, as well as the inductive hardening of the jaws and the cutting edge, reflect the very high quality of the pliers, which will satisfy even the most demanding user completely.

The blue-black handles are made of a multi-component TPR (thermoplastic elastomer), which has a hard and a soft component for a comfortable grip with optimum power transmission. The ergonomic shape of the pliers handle also has a positive effect on the handling of the round nose pliers. Wide moulded collars on the pliers head prevent slipping and increase safety when using the pliers.

Features of the curved round nose pliers from Högert

The curved round nose pliers from Högert are a multifunctional tool for gripping and cutting and are generally referred to as needle nose pliers or telephone pliers and are mainly used for wiring thin cables, for example network or telephone connection cables, which usually have a small nominal cross-section of 0.6mm² or 0.8mm². The two jaws are connected to each other via a solid, inserted joint and are made of hardened chrome vanadium steel in accordance with DIN 5745. In direct comparison to other tool steels, this special steel has the advantage that it is particularly hard and robust and therefore contributes to the significantly longer service life of the lateral cutting edges and the serration of the gripping surfaces. Induction hardening achieves a very high Rockwell hardness with a hardness of 58-62HRC, which is particularly noticeable when cutting solid conductors and hard wire.

The only notable difference between the curved and straight pointed pliers is, as the name suggests, that the curved version is angled by approx. 40 degrees. This has the advantage of a clearer view with a natural hand position, especially for very fine work. The angled tip is also more suitable for wiring in narrow switch boxes or hard-to-reach places. As flat-round combination pliers, the bent pliers have flat jaws with a round shape on the outside. This is perfect for bending eyelets and rings. The fine serration of the gripping surfaces guarantees a secure grip without the wire slipping out of the pliers when pulling or bending. In contrast to the 160 mm version, the larger 200 mm long needle nose pliers have a burner hole with coarse gripping teeth for the best possible grip when gripping rods, pipes or profiles. However, this is straight and not oval in shape, as is the case with conventional combination pliers. The side cutting edge, which is closest to the joint, is present on all our needle nose pliers and is used to cut wires, cables, wooden rods and much more by wedge cutting. The length of the cutting edge varies depending on the size of the pliers.

The blue and black handles are not just for looks, although the pliers are also impressive in this respect. The two colours are rather due to the different degrees of hardness of the plastic coating made of thermoplastic elastomer. The firm mixture provides stability, while the soft component in black creates a pleasant grip. This is particularly advantageous when applying higher pressure, for example when gripping with the front tip of the curved round nose pliers. The brand name, which can be seen inside the gripping surface, consists of the blue, harder elastomer component and maximises the grip of the otherwise smooth surface. This, as well as the pronounced collars on the front of the handle, provide safety and protection against slipping and offer an optimum grip even with wet hands. As the needle nose pliers, especially the handles, are not manufactured and VDE-tested in accordance with DIN EN IEC 60900, working under voltage is not permitted.

Specific data of the curved round nose pliers 160mm

- Total length: 160mm

- Head width: ca. 17.7mm

- Head length: ca. 89.5mm

- Jaw width: ca. 8.9mm

- Centre width: ca. 1.7mm per side

- Arc angle: ca. 40°

- Arc length: ca. 27.6mm (Flat, finely toothed)

- Cutting edge shape: Lateral cutting edge with bevelled edge

- Cutting edge length: ca. 11mm

- Weight: ca. 148g

Specific data of the curved round nose pliers 200mm

- Total length: 200mm

- Head width: ca. 16.2mm

- Head length: ca. 61.8mm

- Jaw width: ca. 8.1mm per side

- Centre width: ca. 2.3mm per side

- Arc angle: ca. 40°

- Arc length: ca. 32.2mm (Flat, finely toothed)

- Burner hole: ca. 14.8mm (straight, roughly toothed)

- Cutting edge shape: Lateral cutting edge with bevelled edge

- Cutting edge length: ca. 12.9mm

- Weight: ca. 194g

Application and handling of curved round nose pliers

The curved round nose pliers from Högert are basically combination needle nose pliers, which are often referred to as telephone pliers by craftsmen. The pliers owe this name primarily to the tip, which has a significantly smaller width than conventional flat nose pliers or combination pliers and is therefore particularly suitable for thin cables and wires, such as when connecting telephone lines in a telephone socket. When connecting LED strips to each other or to the required transformer, cables with a very small cross-section are also used. These are often soldered directly to the solder contacts of the narrow strip lights. The fine wires can be gripped very precisely with the curved needle-nose pliers and positioned at the desired point for soldering. The same applies when soldering resistors, capacitors and other electronic components on a circuit board. Here too, the very precisely machined pliers head is perfect for gripping the tiny components and positioning them on the circuit board without damaging the usually sensitive components. The smaller round nose pliers are particularly suitable for such delicate work, as the smaller distance between the tip and the joint, combined with the smaller handles, means that they sit comfortably in the hand and guarantee extremely precise and fine motorised work.

The long tip is bent round on the outside of the jaws and tapers from the joint to the tip. This makes the pliers perfect for forming wire ends into eyelets or bending small rings from craft or florist's wire. Even when working with precious metals such as gold and silver, for example when bending eyelets for jewellery pendants, clasps for bracelets and necklaces or when shaping rings, the round nose pliers are an excellent tool. The 40 degree angled tip, in contrast to the straight round nose pliers have the decisive advantage that even with filigree work the view is not restricted by the hand.

NOTE: Due to the compact design with an overall length of just 160 mm, the smaller of the two needle nose pliers only has a curved, finely serrated jaw surface and a side cutter. The larger version, with its flat burner hole, also offers the option of holding objects extremely firmly with the coarse gripping teeth. However, these are quite sharp-edged, so they can certainly scratch surfaces. For sensitive plastic or painted surfaces, it is advisable to place a soft cloth between the object and the jaws to prevent damage.

A cutting tool is often required when wiring, soldering and bending wires and thin sheet metal. In order to avoid having to switch to a different pair of pliers, needle nose pliers usually have a cutting surface that is arranged on the side, just like a side cutter. The wedge cutting edges of our round nose pliers are precision-milled and have a slight bevelled edge. The double-sided cutting edge not only cuts thin copper wires effortlessly, but also enables you to cut through fine sheet metal, hard florist's wire or cord and string.

Application examples for the round nose pliers with curved tip

- The curved tip is ideal for precise gripping and holding in tight, hard-to-reach places

- The angled tip means that the view of the tip of the pliers is not restricted by the hand

- The flat burner hole of the larger pliers holds rods and pipes securely with the coarse gripping teeth

- The round shape of the tapered pliers jaws is ideal for bending wires into eyelets and rings

- The filigree tip is very helpful when wiring thin, fine cables, e.g. telephone cables

- The robust side cutting edge is perfect for cutting wires, cords and electrical cables

WARNING: Our curved needle nose pliers with multi-component handles made of thermoplastic elastomer are not suitable for working under tension. For such applications, however, we also offer in our online shop VDE pointed nose pliers curved with protective insulation up to 1,000V AC at favourable prices.

Data on the Högert curved round nose pliers

- Product type: Pliers

- Material (Handle): 2-Component TPR

- Material (Jaw): Alloyed chrome vanadium steel

- Joint type: inserted joint

- Hardness (jaws): HRC 58-62

- Colour: Black-Blue

- VDE-tested: No

- Total length: 160mm or 200mm

- Tip shape: bent

- Ergonomically shaped: Yes

- One-handed operation: Yes (on both sides)

- Additional Information

Additional Information

Product-ID ZANG0007 Delivery Time Dispatch within 2 - 3 working days Material Alloyed chrome vanadium steel Color Black-Blue - Reviews