Facade rivets aluminium (unpainted)

Our unpainted aluminium facade rivets are approved for facade cladding with HPL panels or aluminium composite panels and are ideal for mounting on substructures made of aluminium profiles.

✓ Corrosion resistant

✓ Unpainted version

✓ Various sizes

✓ With facade approval

✓ Made in Germany

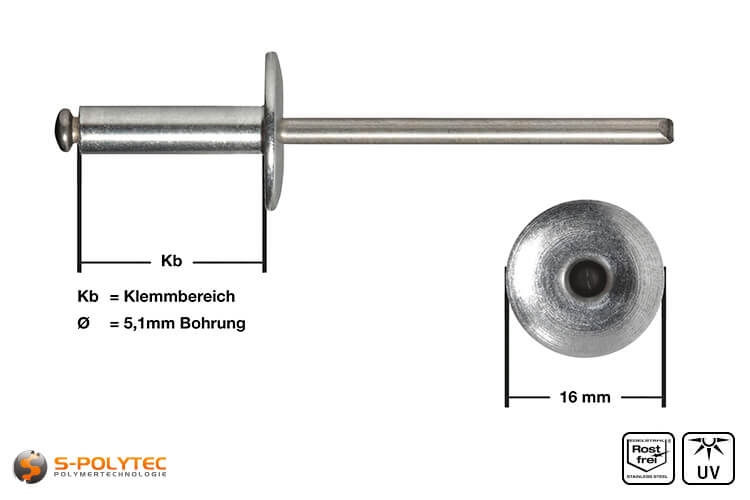

The bare facade rivets with 16mm head diameter are available in the lengths 5x14mm, 5x16mm and 5x18mm.

The item is in stock

Dispatch within 2-3 working days

- calculate the price

- from 20 Items €0.75/ pc. (Base Price €0.75/ pc.)

- from 50 Items €0.69/ pc. (Base Price €0.69/ pc.)

- from 100 Items €0.57/ pc. (Base Price €0.57/ pc.)

- from 250 Items €0.46/ pc. (Base Price €0.46/ pc.)

- from 500 Items €0.35/ pc. (Base Price €0.35/ pc.)

All prices include 19% VAT.

0,00 € / pc.

0,0000 kg / pc.

All prices include 19% VAT.

- Description

Unpainted aluminium facade rivets

High-quality AlMg3 alloy ✓ With facade approval ✓ Made in Germany ✓

Our facade rivets made of unpainted aluminium are available with a head diameter of 16mm in the sleeve sizes 5x14mm and 5x16mm as well as 5x18mm. Depending on the chosen design, the large-head blind rivets have a facade approval for HPL panels or aluminium composite panels from various manufacturers and are therefore ideally suited for the construction of facade cladding and balcony surrounds on an aluminium substructure.

Like all our facade rivets, the blank rivets are also manufactured in Germany and are characterised by precise production in high quality. Because substructures for facade cladding are normally constructed from aluminium profiles, the rivets are also made of a corrosion-resistant aluminium alloy. Only the rivet mandrel is made of stainless steel and contributes to a secure rivet joint, even with heavy HPL panels, by means of a higher tightening torque. The rivet mandrel breaks at the predetermined breaking point when the tightening torque is reached, so that only the aluminium rivet joint remains.

We offer our facade rivets at attractive graduated prices. This does not mean, however, that you are limited to purchasing large quantities. You can buy the unpainted rivets from us in exactly the quantity you require. And that already from one piece. Without any minimum quantity or fixed packaging units.

-

Scope of delivery:

- 1 x aluminium facade rivet (unpainted)

TIP: For our facade rivets you need a tool that is suitable for riveting blind rivets, e.g. a battery-powered blind rivet gun.

Characteristics of unpainted facade rivetsIn contrast to our rivets with head coating, the facade rivets are blank, so that the typical colour of the aluminium remains visible. Therefore the rivets can be used for almost all facade panels. An inconspicuous installation, as with our colour-matched rivets, is therefore not possible, but especially the aluminium composite panels in brushed stainless steel look, as well as our silver aluminium composite panels, match the unpainted facade rivets very well. Depending on your taste, it is also possible to fix white, black, grey or coloured plastic panels in a high-contrast visual appearance, because like all our facade rivets, the bare aluminium rivets also have a facade approval, which varies depending on the panel material used and the manufacturer.

Aluminium is a weatherproof and corrosion-resistant alloy, so that the rivets can be used for both indoor and outdoor fastening.

WARNING: Aluminium rivets are only suitable if the substructure of the facade cladding is also made of aluminium. For steel or stainless steel constructions, stainless steel facade rivets should be used instead to reduce the risk of contact corrosion.

Technical data of aluminium facade rivets

- Colour: Aluminium (unpainted)

- Hollow rivet diameter: 5,0mm

- Hollow rivet length: 14mm, 16mm or 18mm

- Head diameter: 16mm

- Material head: Aluminium

- Material rivet mandrel: Stainless steel

- Material sleeve: Aluminium alloy AlMg3

- Head shape: Large head, round, flat

- UV resistance: Very good

- Weather resistance: Very good

- Corrosion resistance: Very good

Facade rivets have a certain clamping range, depending on the selected size. Here it is important to ensure that the total thickness, which results from the thickness of the plastic sheet and the thickness of the substructure, is within the clamping range. If the value is exceeded or undercut, the rivet will not be held securely.

-

Clamping area:

- Aluminium facade rivet 5x14mm: min. 5,5mm-max. 9,0mm

- Aluminium facade rivet 5x16mm: min. 7,0mm-max. 10,5mm

- Aluminium facade rivet 5x18mm: min. 9,0mm-max. 12,5mm

Mount facade panels with aluminium facade rivets

Facade rivets are an efficient and durable fastening method when screwing is not possible, for example, when only a one-sided assembly from the front or visible side is possible. The rivet is inserted with the rivet sleeve first, through the holes in the panels and substructure, until the rivet head lies flat on the panel surface. For riveting, the stainless steel riveting mandrel is inserted into the mouthpiece of the riveting tool and the tool is operated until the mandrel has reached the tightening torque and breaks. If a riveted joint is correctly made, it can be loaded immediately and does not loosen itself, as it can happen with screwed joints.

When installing facade claddings and balcony surrounds, it is not only important to ensure professional installation, which usually has to be carried out without constraint, but also the size of the rivet. The large-head blind rivets with a diameter of 16mm have a building authority approval depending on the size. For the rivets in the size 5x14mm there is an approval for aluminium composite panels of the manufacturers Alpolic and Alucobond. For the larger rivets, on the other hand, a facade approval for HPL panels from the manufacturers Trespa ®and Fundermax is guaranteed if they are installed professionally. Sliding points are defined for a fastening that is free of tension even in the event of thermal expansion, where rivets are riveted with special special gauge mouthpieces. These ensure the specified gap distance between the panel and the rivet head and are screwed into the riveting device used. It is important to ensure that the nose pieces are adapted to the contour of the large-head rivets and that the nose piece is suitable for the material of the panel, as the gap distance varies depending on whether HPL panels, fibre cement panels or aluminium composite panels are to be fastened by rivets.

-

Matching mouthpieces:

- Special gauge mouthpiece type ALU-16: For aluminium composite panels (e.g. Aludibond, Alucobond, Alpolic, Alucom, etc.)

- Special gauge mouthpiece type HPL-16: For HPL panels (incl. Trespa®, Kronoplan, Fundermax, Resopal, etc.)

- Special gauge mouthpiece type HPL-16: For fibre cement boards (e.g. Eternit, Promat, Fermacell, etc.)

For the drilling of the substructure, as well as the fixed points in the panel when mounting without constraint, we recommend our ground HSS drill with 5.1mm. However, this would wear out too quickly with HPL, so we recommend our solid carbide drill bit with a diameter of 6mm for the fixed points of the hard HPL panels. For sliding points the holes are only drilled larger in the plate. In this case, diameters of 8mm - 10mm are recommended to ensure sufficient play in the expansion of the plates due to the effect of heat. The matching HSS drills for plastics and aluminium, as well as HPL drills made of solid carbide, are also available in our online shop at favourable prices.

The listed brand names Trespa®, Kronoplan, Fundermax, Resopal, Aludibond, Alucobond, Alpolic, Alucom, Eternit, Promat and Fermacell are registered trademarks and serve only as examples of the usability of our facade rivets. Whether a facade approval is guaranteed for a panel from the respective manufacturer must be checked in each individual case.

- Additional Information

Additional Information

Product-ID AFN-16XX-0000 Delivery Time Dispatch within 2-3 working days Material Aluminium (AlMg3) Rivetsize No Shape rivethead Large head, round, flat Diameter rivedhead 16mm Version various Color accuracy No information available Color Colorless Color designation Aluminium unpainted - Reviews