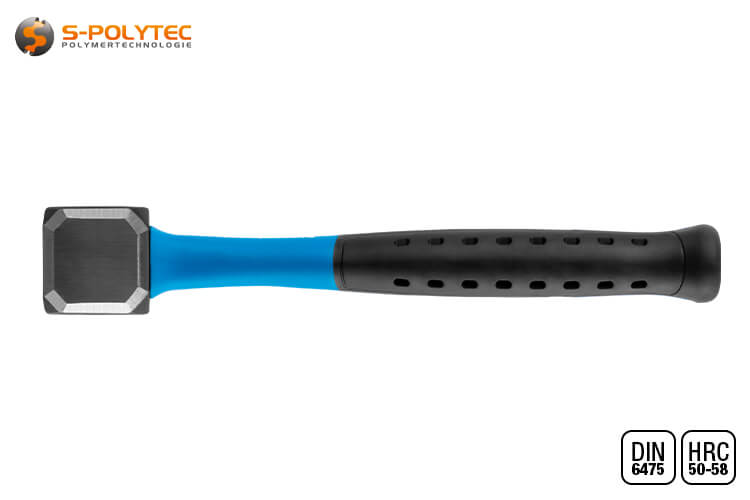

Mallet with fibreglass handle 1000g

The Högert mallet with glass fibre handle and a head weight of 1000g is the all-purpose weapon in the trade and ideal for stone and paving work, for breaking stones, concrete and paving stones or for chiselling.

✓ Forged C45 steel head

✓ Vibration-damping handle

✓ Hardened tracks with 50-58 HRC

✓ Head shape according to DIN 6475

✓ Non-slip 2K handle

The robust fibreglass handle with rubberised grip is shock-absorbent and significantly reduces vibrations.

The item is in stock

Dispatch within 2 - 3 working days

- calculate the price

€13.90 / pc.

1,2130 kg / pc.

All prices include 19% VAT.

- Description

Mallet with non-slip two-component fibreglass handle

Vibration-damping ✓ Hardened tracks ✓ Head in accordance with DIN 6475 ✓

The Högert hammer with glass fibre handle and a head weight of 1000 grams is a proven and popular striking tool for working stone, concrete and paving and is used by countless tradesmen. The compact, solid head made of C45 steel is forged in accordance with DIN 6475 and has oppositely arranged tracks that are hardened separately. This achieves a very high hardness of 50-58HRC on the striking surfaces. The handle is positioned in the centre of the head and is made of a very robust and impact-resistant two-component glass fibre material, whose high quality of workmanship leaves nothing to be desired.

In contrast to conventional solid wood handles, the fibreglass handle with rubberised grip is shock-absorbent and effectively reduces vibrations from the high impact force. This protects the wrist, even if the work with the small heavyweight is somewhat longer. The ergonomic shape, as well as the holes in the rubber coating arranged at right angles to the handle, also noticeably increase working comfort. Compared to fitter's, lath or carpenter's hammers, the handle of a mallet is shorter and therefore offers a perfect balance between powerful impact force and maximum control of the heavy hammer head.

Features of the 1kg mitten with fibreglass handle from Högert

With the Högert hammer with fibreglass handle and a head weight of 1000 grams, we offer a high-quality hammer in craftsman quality that exceeds the expectations of experienced craftsmen or dedicated DIY enthusiasts thanks to its very high quality of workmanship. Thanks to the combination of the solid, short hammer head and the lightweight fibreglass handle, this mallet not only impresses with its impressive weight, but also with its robust construction. The 1kg head with double-sided striking surface ensures a powerful and efficient transfer of energy, making work more effective.

The mallet is a hammer with a shortened handle, squat head and two identical square impact faces, the so-called lanes. The design of the hammer is described in DIN 6475 and is manufactured exactly according to this standard. The solid head with a net weight of 1000g is forged from C45 steel and completely burnished except for the lanes, which gives the small heavyweight a more attractive appearance and also provides effective protection of the steel against external influences. In contrast to the rest of the head, the striking surfaces on both sides are extra hardened and achieve a Rockwell hardness of 50-58HRC to ensure a long service life and constant striking force. The bevelled blades have a generous surface area of 40mm x 40mm. The construction, a combination of a compact hammer head and a short hammer handle, is designed to achieve an optimum balance between weight and handling.

The robust 2K fibreglass handle is not only lightweight, but also extremely resistant to shocks and vibrations. It reduces wrist fatigue and ensures comfortable handling, even during long work sessions with the heavy 1kg hammer. The ergonomic shape, as well as the rubberised grip area, which has vibration-damping properties, is particularly noticeable when the hammer hits hard stone or a chisel with high impact energy. This is made possible by numerous holes in the rubber coating, which are arranged at right angles to the handle. These holes also effectively ventilate the palm of the hand, so that the hand sweats less, thus ensuring a perfect grip on the mitten at all times.

Advantages of the Högert mallet with fibreglass handle

- The 1000 gram hammer is manufactured in accordance with DIN 6475

- The head with hardened tracks is made of forged C45 steel

- The fibreglass handle is extremely robust and reduces vibrations

- The two-component handle has a non-slip, rubberised grip surface

- Cross holes in the grip surface reduce the impact energy and protect the joints

- The compact hammer head is perfectly balanced on the short fibreglass handle

- The bevelled edges on both sides reduce sharp edges

- In contrast to wood, fibreglass is impact-resistant and extremely durable

- The ergonomically shaped handle is optimised for the high head weight

Use and handling of a mitten

The original use of a sledgehammer was for stonemasons and stone carvers and is therefore often referred to as a stonemason's hammer. However, this has long been history and the mallet is now also used in countless other trades. The short handle and the heavy, compact head are perfectly matched to achieve a high, constant impact force for working stones, concrete or paving stones. However, this is not usually done directly with the hammer, but by hitting chisels, which are available in a wide range of sizes and designs.

Typical applications include chiselling slots in masonry to lay cables and pipes flush-mounted. Here, the hammer is struck with one hand on a narrow chisel, which is held by the other hand so that it penetrates the plaster layer or masonry and breaks it at the desired point. The walls are usually cut beforehand using a so-called slotting cutter or a cut-off grinder with a diamond saw blade to prevent the edges from breaking off too roughly during slotting. The 1-kilo chisel is also a very good choice for smaller wall breakthroughs, because in combination with a chisel you have very good control over the size and intensity of the breakthrough. For larger caulking jobs, however, an electric caulking hammer is advisable, even if the ergonomic shape and the vibration-damping fibreglass handle noticeably reduce fatigue. However, stonemasonry work, as well as fitting paving stones in road construction or garden landscaping, are still among the most common practical examples. Here too, a chisel is generally used.

However, a hammer is not exactly the best choice for hammering in nails. The short handle is definitely at a disadvantage here. The extremely intense impact force is also usually too high when it hits the nail, meaning that even larger nails can bend quickly. On the other hand, hammering in impact anchors as robust masonry anchoring in concrete, as well as fastening mounting hole tape with Fixpins and a corresponding setting tool, are examples of applications that benefit from the high impact force.

Sledgehammer or mallet?

A sledgehammer is sometimes also referred to as a sledgehammer, although this is not correct. The main difference between a sledge hammer and a mallet is the shape of the head, which has two opposing striking surfaces, known as faces, on the mallet. However, the typical sledge hammer in accordance with DIN 1042 only has a face on one side, whereas the opposite side has a tapered fin. This head shape is more reminiscent of an oversized locksmith's hammer than a mallet, which in turn owes its name to the compact, squat head shape with the leaning appearance of a closed fist. In addition, the sledge hammer usually has a longer handle, which is also available as a two-handed version depending on the weight.TIP: When working with stones, concrete or paving stones, flying stone splinters cannot be ruled out, so care should be taken to wear appropriate protective clothing in the form of protective gloves and goggles.

Technical data of the Högert hammer

- Product type: Hammer

- Material (Head): Hardened C45 steel

- Material (Shaft): 2K fibreglass (rubberised)

- Head shape: Mallet

- Weight (Head): 1000g

- Face shape: Square (both sides)

- Face area: 40mm x 40mm

- Length (shaft): 22cm

- Weight (shaft): 213g

- Total length: 26cm

- Total weight: 1213g

- DIN Norm: DIN 6475

- Commercial use: Permitted

and care of the 1kg mitten with glass fibre handle

The hammer is designed to withstand the highest loads from craftsmen and is made from high-quality materials that are characterised by an above-average service life. It does not require any special care. Only occasional cleaning is recommended to remove dirt from the hammer head, especially the tracks and the handle, in order to maintain its attractive appearance. In addition, dust and dirt should be removed from the cross holes in the handle at regular intervals in order to maintain the impact-absorbing properties of the handle without restriction

WARNING: A mallet is an impact tool for striking, not for hitting. A hammer should never be used to strike another hammer.

- Additional Information

Additional Information

Product-ID FHMR01 Delivery Time Dispatch within 2 - 3 working days EAN/GTIN 5902801286605 Material Hardened C45 steel Property Sledgehammer with fibreglass handle 1000g - DIN 6475 Weight 1.2130 - Reviews