Flange nuts (galvanised steel)

The flange nuts made of galvanised carbon steel with non-slip knurls prevent the screw connection from loosening due to vibrations and ensure perfect pressure distribution for high loads, as well as a surface-friendly assembly.

✓ Galvanised carbon steel

✓ Vibration-resistant fixing

✓ Optimised pressure distribution

✓ No need for washers

✓ For indoor and outdoor use

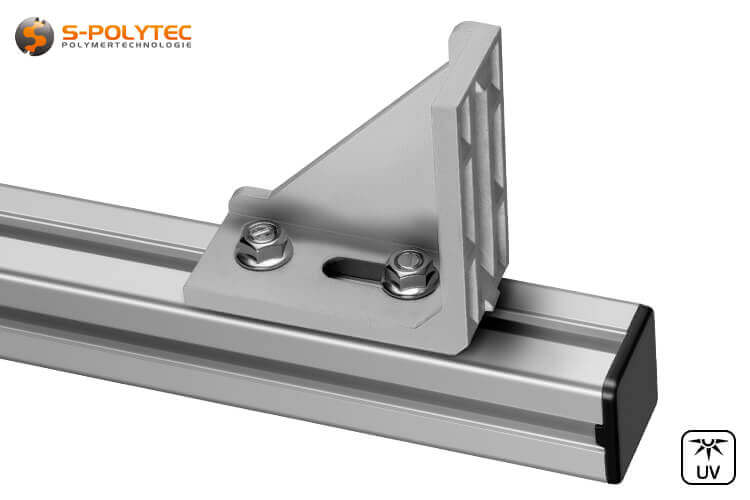

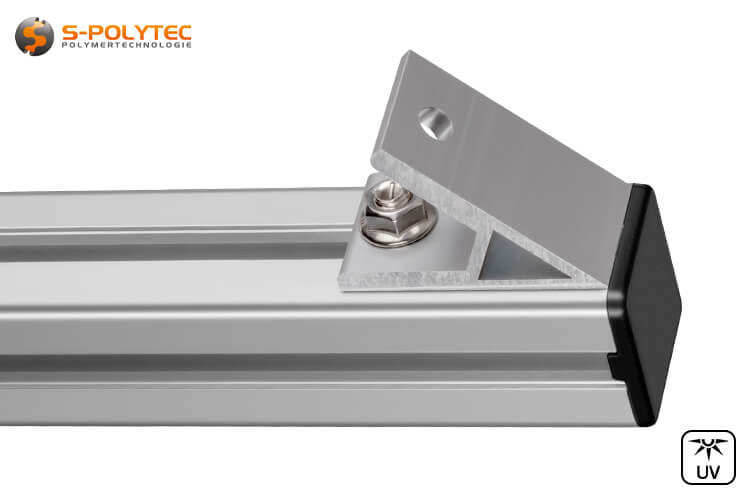

Flange nuts are ideal for securely fastening plates to construction profiles using hammer head screws.

The item is in stock

Dispatch within 2-3 working days

- calculate the price

- from 10 Items €0.08/ pc. (Base Price €0.08/ pc.)

- from 20 Items €0.07/ pc. (Base Price €0.07/ pc.)

- from 50 Items €0.06/ pc. (Base Price €0.06/ pc.)

All prices include 19% VAT.

0,00 € / pc.

0,0000 kg / pc.

All prices include 19% VAT.

- Description

Flange nut made of galvanised steel - with knurling

Optimal pressure distribution ✓ Vibration-resistant fixation ✓ Various sizes ✓

Our flange nuts are available in a range of thread sizes at particularly affordable prices. The nuts are made of a high-quality carbon steel alloy, which is characterised by a very high strength and resilience. For increased corrosion resistance, the flange nuts are surface-treated with a galvanised coating, making them suitable for outdoor use or in environments with high humidity. The flange's larger contact surface helps to distribute pressure evenly across the surface and is particularly advantageous when used with materials such as wood, light metal or thin plastic sheets, which are sensitive to point loading or could easily be deformed. An additional knurl on the underside of the nut serves as a screw lock.

Flange nuts are versatile and reliable fastening elements that offer greater safety and stability compared to a simple hex nut. They also distribute the load better over the surface without the use of a separate washer due to the larger contact area, so that the surface is significantly better protected against damage and breakouts. In combination with the hammer-head bolts, the special nuts are the perfect solution for flexible and resilient fastenings of panels and assembly objects to construction profiles.

NOTE: A spanner or a hexagonal socket is required to tighten the flange nuts. The spanner width for the nut with M6 internal thread is 10mm. The flange nut with M8 internal thread has a spanner width of 13mm.

Properties of our flange nuts made of carbon steel

Flange nuts are special nuts that have a broadened contact surface at the lower end. This flange distributes the contact pressure more evenly over the surface of the material to be fastened, thus preventing breakouts or deformations when the screw connection is under load. In particular, when large forces have to be transmitted and a high degree of stability is required, a flange nut offers advantages over a conventional nut due to the pronounced collar. The flange acts like a washer, eliminating the need for additional fastening components. This reduces assembly time and material costs, which contributes to increased efficiency and profitability, particularly in industrial applications such as mechanical engineering or the automotive industry.

The disc nuts with non-slip knurl on the flange prevent the screw connection from loosening. They are therefore also referred to as knurled flange nuts or flange knurled nuts and are a preferred choice in applications where vibrations or high mechanical loads occur, thanks in particular to their locking function. This is particularly noticeable when constructing machines and systems made of construction profiles, where machine components or covers are fastened with hammer head bolts and flange nuts to ensure a permanently secure connection without the risk of the screw connections loosening during operation. Thanks to the special serration on the underside, flange nuts also provide an increased safety feature for children's play equipment and climbing frames.

NOTE: Flange nuts have a larger external diameter than a conventional hex nut without an integrated collar. Therefore, before installation, it should be ensured that there is sufficient space available for screwing on the nut. An example of this is our bow handles for construction profiles, whose external diameter of the mounting holes is suitable for holding a cylinder screw, but not for mounting with a hammer screw and nut.

Assembly and use of flange nuts

Flange nuts are screwed onto the thread of a bolt or a threaded rod of identical diameter and tightened to a specific torque, depending on the requirements of the bolted connection. This requires a standard spanner, a socket spanner or a ratchet with a socket whose size corresponds to the spanner width of the hexagonal nut. The advantage of a flange nut during assembly is that the use of spring washers or washers can be dispensed with, since the integrated flange acts like a washer and the anti-slip serration on the underside contributes to a vibration-proof fixation that prevents the screw connection from loosening or coming loose over time due to vibrations or mechanical loads.

The larger contact surface of a nut with an attached flange distributes the tightening torque better and is therefore perfect for fastening pressure-sensitive materials such as wood, plastic, light metal or thin sheet metal. This way, the nut does not press into the surface of the material, even without a washer to distribute the load, and is therefore ideal for mounting panels to cover profile constructions with hammer head screws or fence boards with threaded screws.

TIP: For cladding profiled structures with weatherproof HPL or aluminium composite panels, we recommend hammerhead screws and flange nuts, as these provide a simple and efficient means of installation. In order not to impair the panels' ability to expand and contract, a poly washer should be used as a sliding underlay between the profile and the panel surface. Care should be taken to ensure that the installation is free of constraints, with fixed and sliding point fixings.

Flange nuts are very popular in countless application areas. In the automotive industry, they are often used to fix components firmly and securely against vibrations, for example in engines, chassis, plastic covers, headlight housings or exhaust systems. In mechanical engineering, flange nuts are used because of their high strength and stability, which are essential for precise and secure fastenings in large machines or conveyor systems. In the construction industry, especially in steel construction, which includes fall protection such as railings or balcony balustrades, but also elevator construction, knurled flange nuts are very common because thanks to the increased contact surface they enable resilient and secure connections at high tightening torques without putting too much point load on the material and surface.

Examples of applications for our flange nuts

- Flange nuts are ideal for mounting panels on construction profiles using hammer head screws

- In mechanical engineering, the flange nuts with knurls provide a secure fastening against loosening

- Flange nuts provide a stable, secure screw connection between table tops and underframes

- In the automotive industry, flange nuts are used to attach plastic covers and lights

- Flange nuts are ideal for fence construction because the larger contact surface does not press into the wood

Technical data for flange nuts

- Material: Carbon steel (galvanised)

- Colour: Silver

- Thread type: Internal thread

- Ø Thread: M6 or M8

- Ø Outer thread: 13.5mm or 17.5mm

- Width across flats: 10mm resp. 13mm

- Height: 5.9mm resp. 7.5mm

- Weight: 3.5g resp. 6.5g

- UV-resistance: Excellent

- Weather resistance: Excellent

- Corrosion resistance: Sufficient

- Additional Information

Additional Information

Product-ID FGM-0000 Delivery Time Dispatch within 2-3 working days Property Flange nuts (galvanised steel) Material Carbon steel (galvanised) Color Silver - Reviews