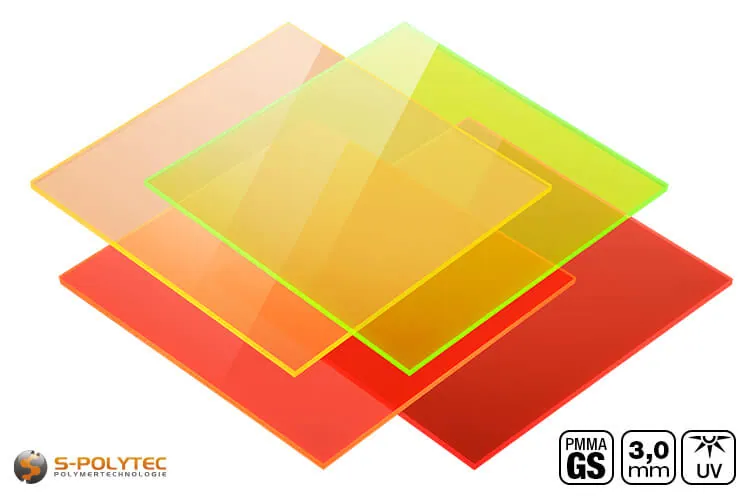

Fluorescent acrylic GS cut to size (transparent)

Our fluorescent acrylic glass GS cut to size with a thickness of 3mm is available in the colours red, orange, yellow and green. Depending on the colour shade, the transparent sheets have a light transmission of 12% to 87%.

✓ Strong colours

✓ High luminous effect

✓ UV- and weather resistant

✓ Enormously resistant to ageing

✓ Excellent surface finish

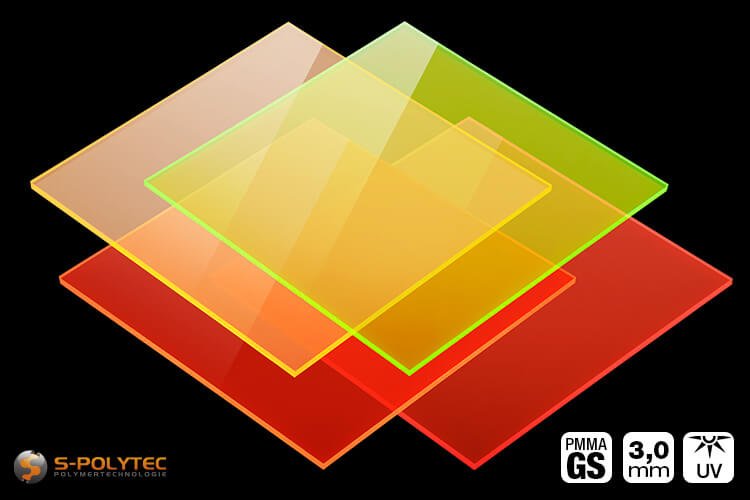

The acrylic glass panels with luminescent effect give the appearance of glowing in vibrant neon colours at the cut edges completely without electricity.

The item is in stock

Dispatch within 2-3 working days

- Panels in Cut

- at pieces 0,00 € (Base Price 0,00 € / m2)

- at pieces 0,00 € (Base Price 0,00 € / m2)

- at pieces 0,00 € (Base Price 0,00 € / m2)

All prices include 19% VAT.

0,00 € / pc.

0,0000kg / pc.

All prices include 19% VAT.

- Description

Buy fluorescent acrylic GS cut to size online at low prices

Weather resistant ✓ High Luminous Effect✓ Optionally in red, orange, yellow or green ✓

We offer the transparent sheets of fluorescent acrylic glass GS cut to size with a thickness of 3mm, optionally in red, orange, yellow or green at favourable prices. The solid acrylic glass sheets are transparent and enriched with high-quality colour pigments as well as fluorescent dyes, which creates an intensive self-luminous effect that occurs especially at the cut edges. Depending on the colour, the colour pigments cause a reduction in the light transmission of the otherwise crystal-clear, transparent sheets. The cast acrylic glass is UV and weather resistant and, with a low water absorption of maximum 0.5%, is one of the weather and water resistant plastics. The glossy, smooth surfaces with a high degree of gloss typical of acrylic glass are protected by a protective film on both sides against damage and scratches that could occur during further processing, storage or transport. However, this film can be easily peeled off the surface.

We offer the acrylic glass cuts online up to a size of 1500mm x 1000mm. Larger formats are also possible on request. The minimum format for sheet cutting, which we can realise with our CNC sheet saws, is 30mm x 30mm. The sawing process produces rough cut edges. By using special saw blades and a sawing programme specially adapted to acrylic glass, the cut edges are very precise, so that hardly any further edge processing is required to smooth the cut edge, unless straight polished cut edges are desired.

Properties of the fluorescent acrylic glass GS in the blank

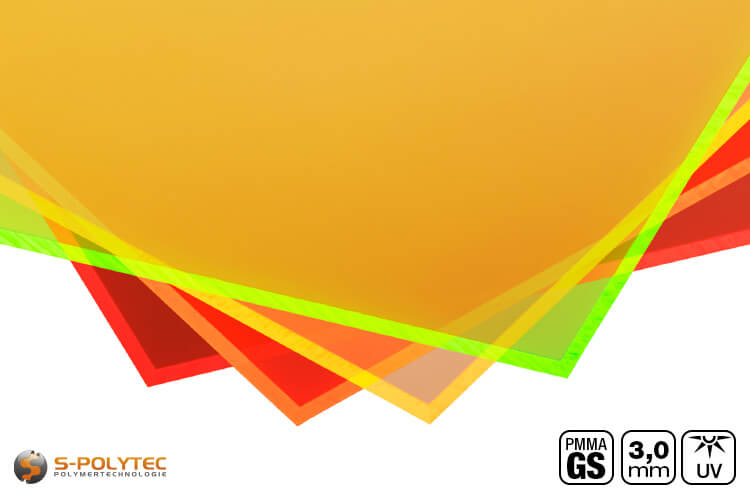

The fluorescent acrylic sheets are not extruded but cast. In this process, the PMMA raw material is mixed with colour pigments and poured into a mould between two sheets, creating a homogeneous sheet with outstanding surface quality. The self-luminous effect is created by the admixture of fluorescent dyes, which is particularly visible at cut edges, as well as in engravings or drill holes. While the effect provides intense colours on the cut edges in daylight, it looks as if the edges are illuminated by a light source, especially in moderate lighting conditions such as dusk.

Due to its chemical composition, acrylic glass is naturally UV and weather resistant. Due to the casting of the sheets, acrylic glass GS is also even more resistant to ageing than extruded acrylic glass XT. This is an important aspect in order to enjoy the colours and luminosity without restrictions for years, without persistent UV radiation causing the sheets to become brittle or the neon-like colours to fade.

- Acrylic glass GS Red fluorescent: similar to RAL3024 (luminous red), light transmission approx. 12%

- Acrylic glass GS fluorescent orange: similar to RAL2005 (neon orange), light transmission approx. 37%

- Acrylic GS fluorescent yellow: Similar to RAL2007 (luminous bright orange), light transmission approx. 72%

- Acrylic GS fluorescent green similar to RAL6038 (luminous green), light transmission approx. 87%

Application examples for the luminous acrylic GS

Coloured acrylic glass with fluorescence is much less common than acrylic glass without a luminous effect. The material is mainly used for trendy home accessories and lighting elements. By thermoforming, bowls, vases and artistically shaped lampshades are created without much effort, which also have a quite high self-luminous effect on the surface due to the curvatures. But fluorescent acrylic glass is also used without thermal deformation. For example, for covers of models made of sticking bricks, true-to-scale models of vehicles or eye-catching shelves and displays for product novelties in retail. With suitable adhesives, these are even very easy to create thanks to our precise cuts.

In modern art, acrylic glass is shaped, cut, bent or glued into the most abstract forms and objects. This creates works of art that attract the viewer's attention, especially in the case of fluorescent acrylic glass. Through the play of light and shadow, it is not always the art object alone, but rather the interplay of the object, the incidence of light and its effect that distinguishes the actual art as such. However, you don't have to be Salvador Dali to do this, because acrylic glass is very easy to work with and so even artfully crafted decorations are easy to realise with a little skill, the necessary tools and a creative idea.

Due to its weatherproof properties, the luminous acrylic glass is enormously popular for making decorations for the terrace or the garden. Especially decorative poles made of multi-coloured elements in the shape of flowers, bees and butterflies are very popular and form an eye-catcher among flowers, blossoms, grasses and shrubs and can also contribute to a cheerful splash of colour in the dreary grey of winter during the cold season.

- Fluorescent acrylic is used to make decorative sticks for potted plants and garden plantings

- The luminous, transparent panels are used for display cases of models and showcases

- Among artists, the easy-to-process acrylic glass is a sought-after material thanks to the self-luminous effect

- For product presentations, the transparent panels with luminous edges attract a high level of attention

- The glowing orange acrylic glass is very popular in the Netherlands for decoration purposes, e.g. at international matches

- The coloured acrylic glass is used in the thermoforming process for lampshades, vases and art objects

- And many more

Processing of fluorescent acrylic glass

Due to its enormous luminosity, fluorescent acrylic glass is mainly used for decorative purposes, where the luminous cut edges play a decisive role. From cutting, to engraving, to gluing or deep-drawing, the colourful acrylic glass can be brought into the desired shape in almost every conceivable way.

Acrylic glass GS cutting and drilling

With fluorescent acrylic sheets, the self-luminous effect of the cut edges is utilised. A clean cut is the decisive factor. With our acrylic glass cuts, further processing is no longer necessary in many cases and thanks to our years of experience in sawing plastics, we guarantee a smooth, precise cut edge. However, sawing acrylic glass is also not a science, so that cutting to size or cut-outs can be carried out with simple tools. A sharp saw blade with medium-density teeth, a low number of revolutions or strokes and a firm base are most likely to produce perfect results. Saw blades that are too coarse or vibrations of the board during sawing can cause chipping or breakage of the board. If the saw blade is too finely toothed, for example metal saw blades, or if the sawing speed is too high, the saw blade will quickly become too hot. This softens the sawdust and it can melt into the cutting edge. For straight cuts, a table saw or hand-held circular saw is very suitable. For small cut-outs, curves or free-form shapes, for example letters or lettering, a jigsaw or scroll saw is the better choice. Routing with a router, or a CNC-controlled portal router, follows the same principle. The panel should rest firmly and be milled at reduced speed and low feed. With a polishing cutter and the right settings, perfect milling edges are possible that almost come close to the cutting pattern of a CO² laser.

Acrylic glass is easy to drill. A simple cordless screwdriver with an HSS drill is sufficient. With a Plastic drill type HK, which is specially designed for drilling brittle plastics, such as acrylic and Plexiglas® or hard PVC, drilling is even significantly easier and more precise, which has a particular effect on the glowing effect of the edge of the drill hole. The drill bit, which is more pointed than normal metal drills, glides more easily through the hard surface and, thanks to the deep drill spiral with elongated spiral twist, also does not get hot as quickly. Regardless of which drill is used, a lower speed should always be selected when drilling. In addition, no pressure should be exerted on the drill bit during drilling and the plate should rest on a firm base to avoid chipping when the drill bit comes out.

Polishing the saw-rough cut edge can somewhat enhance the luminous effect of the fluorescent panels, but also requires a relatively high amount of work. This requires a sanding block with fine sandpaper in various grit sizes. Starting with a fine grit to even out unevenness and grooves, the sandpaper is selected finer and finer with each work step. In the last step, a polishing paste such as our acrylic and Plexiglas®polish is used. PMMApolish, the surface of the cut edge is polished to a high gloss. Less work, but with considerable risk, is flame polishing, in which a gas burner is used to heat the edges so that the rough surface is smoothed by melting. However, if one remains in one spot for too long, the acrylic glass can burn. Damage caused in this way can only be repaired with a great deal of effort, provided the burn is very slight. With laser cutting, as we offer with our acrylic glass sheets in laser cutting, the edges no longer have to be polished, because through the non-contact cutting process, the cut edges are even, smooth and shiny. Further advantages of laser cutting are the very low dimensional tolerances, as well as the possibility of cutting individual shapes, curves and bends, as well as fixing holes and cut-outs.

Acrylic glass GS printing, lacquering and foiling

In principle, acrylic glass can be very well printed, lacquered or covered with a film. However, these surface treatments are hardly ever used for luminescent acrylic glass. The fluorescent ones are used less because of the smooth, transparent surfaces than because of the luminescent effect of the cut edges. Nevertheless, fluorescent sheets in red, orange, yellow or green can be used to create eye-catching signs or product displays that draw attention to the company or product by means of additional labelling with a self-adhesive film.

Acrylic glass GS engraving

Acrylic glass can be gently engraved with a CO² laser. Engraving is also very easy with a CNC milling machine and leads to very good results. With a multifunctional tool, for example a Dremel®, with a milling insert, engraving is also possible without special machines. The tool is carefully moved over the smooth surface at a low speed, just like drawing by hand. Because coloured acrylic glass plates are transparent, the desired motif can be stuck to the back of the plate with a little adhesive tape and the contours traced with the milling tool. It should be noted, however, that the graphics, especially if they contain text, must be engraved mirror-inverted so that the engraving remains legible from the smooth side.

Especially with the fluorescent plates, engraving leads to a special eye-catcher, because due to the very high luminous effect that occurs at the cut and milled edges, the engraving also appears as if it were glowing.

Glue and seal acrylic glass GS

Cast acrylic has no internal stresses due to the manufacturing process and can therefore be bonded very well with solvent adhesives without the risk of stress cracks appearing at the cut edges. With our Acrylic and Plexiglas®gluePMMAprofi, we offer a low-viscosity cold welding adhesive that has a very high capillary effect due to its water-like viscosity. This means that the adhesive is absorbed into every gap, no matter how fine, and thus ensures secure bonding of the fluorescent acrylic glass. In addition, the capillary effect has the advantage that when the sheets are bonded, a continuous two-dimensional bond is created, which means that the luminescent effect also appears without gaps and bubbles at the bonding points of cut edges.

As an alternative to bonding with solvents, acrylic glass can be bonded with a silicone sealant, both to each other and to other materials. A transparent sealant is also recommended for transparent sheets. The Silicone sealant Parasilico PL is an excellent choice here because it is highly transparent and ensures very good adhesion to very many materials.

Cleaning acrylic glass GS

Acrylic glass can be cleaned in a similar way to glass, but PMMA is sensitive to contact with solvents and alcohols. For this reason, only cleaning agents that are free of these ingredients should be used to clean the surfaces. Conventional washing-up liquid is very suitable for cleaning the glossy surfaces. Special cleaning agents, such as our acrylic and Plexiglas cleaner PMMAclean, not only clean the surface, but also protect it effectively. The antistatic effect of our cleaner also helps to ensure that the plastic does not attract dust as quickly as it would if cleaned with a mild soap solution. Smooth surfaces, regardless of whether they are plastic, glass or painted, should always be cleaned with a soft, lint-free cloth. It is best not to use microfibre cloths, as these can scratch the surfaces over time and make them look dull, so that the fine micro-scratches have to be polished out at great expense with a polishing paste suitable for the surface.

NOTE: Our fluorescent acrylic glass sheets are equipped with a protective film on both sides to protect the surfaces. When processing the surfaces, for example by gluing, printing or engraving, the protective film must be removed beforehand. The protective film must also be removed when deep-drawing the acrylic glass blanks, as the film is not deep-drawable.

- Additional Information

Additional Information

Product-ID 51900C Thickness 3 Delivery Time Dispatch within 2-3 working days Plastic Acrylglas Material PMMA Standard width 1500 Standart Length 1000 Fire behaviour Normal flammability UV resistance UV resistant Color No Color accuracy Color similar to RAL color system - Reviews

- Attachments

You may also be interested in the following product(s)

Acrylic adhesive - S-Polybond PMMAprofi 100ml

S-Polybond PMMAclean - Acrylic and plexiglass cleaner 500ml

S-Polybond PMMApolitur - Acrylic and plexiglas polishing paste 150ml

HSS-G Drill Type HK for Plastics

Transparent acrylic glass GS cut to size (colourless)

Coloured acrylic glass GS cut to size (transparent)