Rigid PVC White cut to size (UV stabilised)

Our white sheets made of rigid PVC in the UV- and weather-stabilised type PVC-MZ are considered waterproof and do not contain any plasticisers. The white PVC sheets are suitable for countless indoor and outdoor applications.

✓ UV-stable design

✓ Suitable for outdoor applications

✓ Rigid PVC without plasticiser

✓ Made in Germany

The white PVCU sheets in UV-stabilised design are available in thicknesses from 2mm to 4mm as millimetre-precise cut-to-size sheets.

The item is in stock

Dispatch within 2 - 3 working days

- Panels in Cut

- Request a sample

Request up to three free samples.

Dimensions of the samples approx. 200mm x 100mm

- at pieces 0,00 € (Base Price 0,00 € / m2)

- at pieces 0,00 € (Base Price 0,00 € / m2)

- at pieces 0,00 € (Base Price 0,00 € / m2)

All prices include 19% VAT.

0,00 € / pc.

0,0000kg / pc.

All prices include 19% VAT.

- Description

White rigid PVC sheets (PVCU, UV stable) cut to size

Weather resistant ✓ No plasticisers ✓ Made in Germany ✓

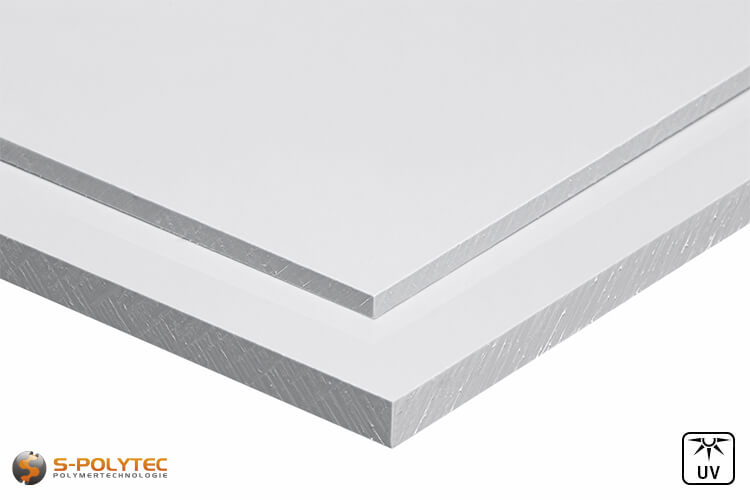

Our white plastic sheets made of rigid PVC are available as UV-stabilized variant in thicknesses of 2mm, 3mm and 4.0mm in cut to size. Thanks to the precise cutting, plastic sheets made to measure are possible from a size of 30mm x 30mm. The maximum size of our blanks is 2000mm x 1000mm. The white sheets are highly pigmented and completely white dyed through. This ensures that cut edges and surfaces have exactly the same white color, whose white shade is very similar to RAL9016 (traffic white) according to the RAL color system. To protect against scratches, the panel blanks are provided with a protective film on one side, which can be easily removed after completion of further processing.

As with all PVC sheets from our online shop, the white sheets are also solid core sheets. In contrast to soft PVC, for example PVC sheets with a foamed core, our hard PVC does not contain any plasticisers, which evaporate from the plastic over time. This means that there is no danger to health even when used permanently in living areas. Due to the additional UV stabilisation, which is achieved through additives during the production of the white PVC sheets, the PVC blanks can also be used outdoors without hesitation.

Properties of our white PVC sheets cut to size

PVC is a dimensionally stable plastic with a high surface hardness, which has quite a high rigidity even in low thicknesses. In contrast to our conventional white PVC sheets, the UV-stable sheets made of rigid PVC have an increased impact strength. This is achieved through additives that also cause the sheets to have improved weathering and ageing resistance, making them suitable for permanent outdoor use. Prolonged exposure to UV radiation does not affect the colour of the white sheets, nor do the sheets become brittle over time.

Rigid PVC is excellent choice for machine cladding and components in machine and plant construction. The very high electrical breakdown resistance also allows it to be used for protective housings for electrical appliances, switch boxes and high-voltage equipment.

Rigid PVC hardly absorbs any water. This makes PVC one of the waterproof plastics that also have very good chemical resistance. PVC-U is resistant to strong acids, alkalis, alcohols, oils, greases, aliphatic hydrocarbons and petrol, for example.

Standards for weatherproof rigid PVC in white

- REACH (EU Chemicals regulation)

- RoHS (Ordinance on the Prohibition of Hazardous Substances in the Electrical Industry)

- PAHs (Directive on compliance with limit values for polyaromatic hydrocarbons)

NOTE: Detailed information on the mechanical, physical and thermal properties can be found in the data sheet for our white rigid PVC sheets with UV stabilisation.

Application examples for UV-stable rigid PVC in white

Rigid PVC is characterised by a whole range of positive properties, so it is hardly surprising that this plastic is one of the most widely used thermoplastics. Due to its enormous durability, as well as its easy machinability, the UV-stabilised version of rigid PVC sheets is used for the production of weather-resistant window frames or patio furniture. PVC is also used for cable ducts, cable conduits, switch boxes, junction boxes or switch cabinet equipment, because PVC is an outstanding insulator and is also considered flame retardant. The very good resistance to alkalis and acids, as well as the fact that PVC is waterproof, means that PVC is often used in tank construction for the chemical industry, as piping for sewage systems or as a resistant floor covering.

- UV-stabilised rigid PVC in white is used for the production of window profiles

- The white PVC blanks are perfect for lightweight direct print advertising signs

- Rigid PVC is ideal for electrically insulating enclosures, covers and switch boxes

- White garden and camping furniture is often made from the inexpensive plastic

- The white rigid PVC can be used for plastic cladding outdoors

- And many more

Processing of rigid PVC in white (UV-stable)

Our white sheets made of UV-stabilised rigid PVC can be processed in a variety of ways. All machining methods that are also used in wood processing are suitable for cutting the sheets to size. In addition, PVCU can be drilled, printed, glued or bonded without hesitation. The durable plastic can also be formed into almost any shape without cutting, for example by thermoforming or deep-drawing.

Cutting and drilling rigid PVC

Even though it is usually not necessary to cut the white PVC sheets to size due to our precise cutting, they can be cut to the desired size in very different ways. Sawing is one of the most common methods. For straight cuts, a circular saw is a very good choice. For curved cuts or cut-outs within the panel, a jigsaw is more suitable. Special attention should be paid to the choice of saw blade. Saw blades with too coarse teeth will cause the panel to break or crack. Saw blades with too fine teeth heat up the cut edge too much, so that a saw blade with medium teeth is most likely to produce a clean cut. As with all plastics, the speed or number of strokes must be significantly reduced to prevent the cutting edge from melting into the saw chip. This is particularly important with PVC, because hydrochloric acid can be produced during burning, which attacks the saw blades. The same applies to milling the white PVC sheets. In addition, the feed rate should not be too high.

Punching, as well as water jet cutting, are also possible techniques for cutting the sheet material to size. Punching is mostly used for smaller panel thicknesses. Waterjet cutting, on the other hand, usually requires thicker panels. Panels with a very low thickness of 1mm or less can even be cut very well with scissors or a sharp knife.

Drilling PVC is possible with commercially available HSS drill bits for metal. However, there are a few important points to note here. Firstly, the speed should be very low when drilling so that the drill does not become too hot due to the high friction and thus burn the plastic. In addition, PVC is a brittle plastic that breaks more easily when drilled with too much pressure than plastics with a higher toughness. This can be avoided by placing the plastic sheet firmly on a base when drilling. Alternatively, there are special plastic drills, e.g. our HK drills, whose geometry is specially designed for drilling brittle plastics. Such drills usually have a significantly reduced point angle and also have a very elongated drill spiral, which removes the chips more quickly. To avoid excessive heat development during drilling, a coolant and lubricant, for example simple liquid soap, can be used.

Printing, lacquering and foiling rigid PVC

The white sheets are excellent for direct printing, so the blanks are often used for printed advertising signs or wall decorations. In most cases, the print is finally laminated with a UV-protective laminate so that the print image shines in rich colours for a long time without fading, even in sunlight. PVC can be very well covered with a film for this purpose. Not only to protect digital prints, but also to create information boards with film lettering, or to change the surface colour of the sheets over the entire surface with a film covering. Especially in the production of window frames and profiles, which have different colours on the inside and the outside, the foiling of the plastic is an inexpensive and widespread practice. For example, the windows facing the living space can be chosen in plain white, while the profile on the outside can be adapted to the house façade with a robust decorative film in anthracite, light grey or even a wood decor.

Bonding and welding rigid PVC

There are various methods available for joining PVC sheets to each other or to other materials. Welding with a PVC welding rod is very common, especially in tank construction. Especially when PVC is to be used for chemical containers, a durable and waterproof welded joint is the best joining method. Welding can also be used very well for housings, for example of electrical devices and systems, but there are also very good solvent-based adhesives for such purposes that ensure a permanent bond between the plastic. This includes, for example, our special adhesive PVCprofiof our own brand S-Polybond, which was specially developed for bonding PVC and ensures a water- and pressure-resistant adhesive bond. If, on the other hand, the white plastic sheets made of rigid PVC are to be bonded to other materials, for example materials from the construction sector (concrete, wood, stone, tiles, etc.), our Parabond 600 assembly adhesive in white very well. This MS polymer adheres to almost all building materials and has an enormous initial adhesion, so that even higher panel thicknesses can be permanently and securely bonded.

Hard PVC thermoforming and thermoforming

Rigid PVC is a thermoplastic and as such is very suitable for producing three-dimensional moulded parts using the thermoforming process. Temperatures between 110°C and 180°C are ideal for thermoforming the white PVC-U sheets. The softening time depends on the thickness of the sheets. For thermoforming, for example light bending or curving, lower temperatures between 110°C and 140°C are usually sufficient. For narrow-radius edging or deep-drawn parts with a high aspect ratio, on the other hand, higher temperatures are recommended. If the temperature is set too high, PVC will burn. This can cause hydrochloric acid to form, which can lead to corrosion of the moulding tools as well as the system and can severely damage them.

WARNING: Polyvinyl chloride releases hydrochloric acid at high heat. For this reason, the white rigid PVC cannot be cut with a CO² laser. When sawing, milling, welding or deep-drawing, care should also always be taken not to burn the plastic or heat it too high in order to counteract the formation of hydrochloric acid.

- Additional Information

Additional Information

Product-ID 70410C Thickness 1-4mm Standart Length 2000 Standard width 1000 Delivery Time Dispatch within 2 - 3 working days Plastic Polyvinyl chloride Material PVC-U (Hard-PVC) UV resistance UV stabilized Color White Color accuracy Color similar to RAL color system RAL color code RAL9016 Color designation Traffic white - Reviews

- Attachments