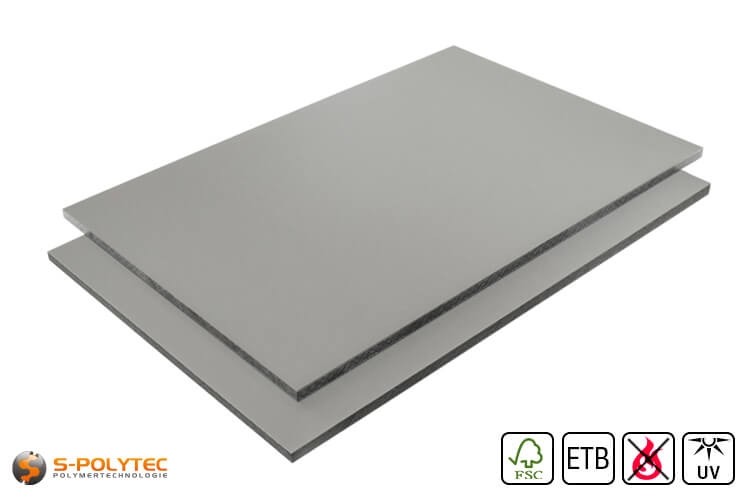

HPL panels dusty grey (RAL7037)

Weatherproof, scratch-resistant HPL sheets for indoor and outdoor use with surface decor on both sides in dust grey (RAL7037) in thickness 6mm and 8mm, made to measure.

✓ UV and weather resistant

✓ Flame retardant

✓ ETB balcony approval

✓ FSC certified

✓ Single-sided protective film

Note: Larger formats available on request due to increased shipping costs

The item is in stock

Dispatch within 2-3 working days

- Panels in Cut

- Request a sample

Request a free sample.

Dimensions of the samples approx. 200mm x 100mm

- at pieces 0,00 € (Base Price 0,00 € / m2)

- at pieces 0,00 € (Base Price 0,00 € / m2)

- at pieces 0,00 € (Base Price 0,00 € / m2)

All prices include 19% VAT.

0,00 € / pc.

0,0000kg / pc.

All prices include 19% VAT.

- Description

HPL panels in RAL7037 (dusty grey) - weatherproof and flame retardant

UV and weather resistant ✓ Flame retardant ✓ FSC-certified ✓

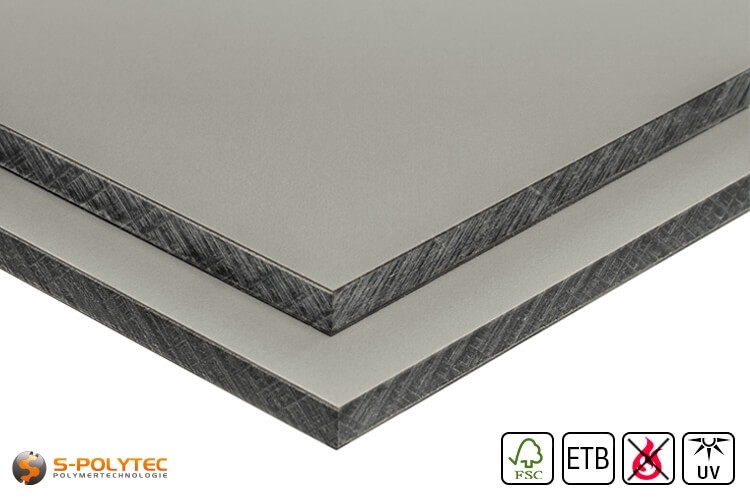

Our HPL panels in a medium grey are manufactured according to the colour RAL7037 (dusty grey). The HPL panels are available in thicknesses of 6mm or 8mm. The core of the decorative panels made of high-pressure laminate consists of several layers of kraft paper, while the surfaces consist of layers of decorative paper dyed in RAL colours. Soaked in resins, the individual layers are pressed together under high pressure to form a solid panel. Our dusty grey HPL panels are UV and weather resistant on both sides. The non-porous surface of our HPL sheets is protected against scratches that could occur on the hard surface before or during processing by a protective film on one side, which can, however, be removed very easily after installation.

Characteristics of our HPL panels in dusty grey

HPL panels made of multi-layer high-pressure laminate are laminate panels in which several layers of kraft paper are soaked in resin, depending on the thickness. The surfaces consist of decorative paper soaked in melamine resin, which is pressed under very high pressure to form a solid, rigid panel. HPL panels are UV-resistant and highly weatherproof and are therefore mainly used as facade panels or as partition walls indoors and outdoors. In order to also be able to use the sheets as balcony cladding, our HPL sheets in RAL7037 also meet the strict requirements of the ETB guideline for fall protection for the thicknesses 6mm and 8mm.

With a very low mass increase of a maximum of 5%, our HPL sheets are considered waterproof and can therefore be used permanently outdoors even in the most adverse weather conditions and rapid temperature changes. The temperature range extends from -30°C to +80°C, so that even very low temperatures do not restrict the usability of the laminate sheets.

Another advantage of our dust-grey HPL decorative panels is their low flammability. While HPL panels are usually classified as normally combustible, our HPL panels comply with the European standard DIN EN 13501-1 B-s2, d0 (comparable with DIN 4102 B1) and are therefore considered flame-retardant.

Approvals and standards for HPL panels in dusty grey (RAL 7037)

- Highly flammable according to DIN EN 13501-1 B-s2, d0 (comparable with DIN 4102 B1)

- Balcony approval in accordance with ETB directive "Components that protect against falling"

- Our HPL panels are classified as A+ according to the standard on VOC emissions

- FSC certified (ecologically sustainable and socially responsible forestry)

High-pressure laminate panels are generally considered environmentally friendly because they are free of heavy metals, organic halogens (fluorine, bromine, chlorine, etc.) and asbestos. Our cuts of dust-grey HPL also meet the requirements of the standard on VOC emission A+, which states that this material strictly adheres to the strict tolerances of chemical emissions, allowing it to be used in offices and interiors without restrictions. In addition, HPL panels are classified as physiologically harmless.

WARNING: Do not use abrasive cleaners, scouring pads or polishing agents to clean the HPL panels. This could have a detrimental effect on the appearance of the grey surfaces and, in the worst case, scratch or damage them.

Millimetre-precise cutting of our HPL sheets in dusty grey

Save yourself the work and simply order your HPL sheets in dusty grey in the size you want.

Sawing HPL panels is a challenge in itself, because special saw blades are recommended due to the high hardness of the solid panels. In addition, the surface can quickly show slight chipping if the saw blade is not toothed finely enough or the speed is not correctly matched to the material.

With our cutting service, we offer you the possibility of ordering your HPL sheets in exact cuts and benefit not only from our many years of experience, but also from our ultra-modern panel saws for horizontal cutting with a very low tolerance of just +/- 1mm. In order to achieve a perfect cut edge with no chipping on the surface, the panels are pre-scored in a special process with an extra-hardened saw blade in order to cut through the panel in the subsequent sawing process.

Based on our maximum format for standard shipping by forwarding agent, only blanks up to a length of 1840mm x 1000mm can be entered via our blank configurator. Standard panels with dimensions of 3050mm x 1300, as well as blanks in larger formats up to a length of 3050mm x 1300mm width are nevertheless possible on request. Please note, however, that shipping costs may be significantly higher in some cases. The delivery time for large formats may also increase slightly, as we only stock the smaller standard format for blanks in our main warehouse.

Cuts of our laminate sheets usually have a rectangular format. However, if you need HPL sheets in other shapes and contours or with bevels and holes, we will be happy to assist you with our milling service. In this case, simply send us your enquiry by email. All we need is a design drawing and details of the desired thickness and delivery quantity in order to send you your personal quotation including shipping costs as quickly as possible.

Application examples for HPL panels in dusty grey

- Our HPL panels in dust grey are flame-retardant and therefore permitted in public buildings

- Thanks to balcony approval (with ETB fall protection), the HPL sheets can also be used as balcony cladding

- As highly weather-resistant panels, the HPL sheets can be used outdoors without hesitation

- Thanks to strict compliance with emission values, the HPL panels are easily suitable as partition walls in offices

- and many more

Processing of HPL panels in dusty grey

High-pressure laminate, such as our double-sided dust grey HPL panels, can be processed without any problems. Sawing, milling, drilling or sanding are common techniques for adapting the panels to the desired requirements in terms of size or fastening. It should be noted, however, that the HPL sheets are very hard and rigid, so that special saw blades and milling cutters are required for cutting with a saw or a milling machine in order to keep tool wear within limits.

For hole drilling, the drill bits used should also be made of carbide or HSS drill bits should be used. With special facade panel drills with a centre point for HPL panels, chipping is not to be expected, so that you can also drill holes without a base or freehand. If you do not have a facade panel drill at hand, we advise you to lay the panels on a firm, level base to minimise surface chipping when pushing the drill through.

Although painting is unnecessary due to the highly weather-resistant surface of our HPL panels, it is basically quite possible. However, an appropriate surface pre-treatment is a prerequisite, such as the use of special primers and lacquers.

For mounting the grey HPL panels on a wooden substructure, we offer you the matching HPL screws in dusty grey with scratch-resistant head lacquer in our online shop at favourable graduated prices. The colour and gloss level of these screws are exactly matched to our HPL facade panels and are made of high-quality stainless steel.

NOTE: Our flame-retardant HPL sheets with balcony approval in RAL 7037 (dust grey) are delivered with a protective film on one side. Please make sure to remove the protective film after working and processing.

Technical data of our HPL panels in dusty grey

- Colour: RAL7037 (Dusty grey)

- Thickness: 6mm and 8mm

- Physical density: 1.35 g/cm³

- Modulus of elasticity: min. 9,000 MPa according to EN ISO 178

- Bending strength: min. 80 MPa according to EN ISO 178

- Mass increase: max. 5% according to EN 438-2.15

- Temperature resistance: -30 °C - +80 °C

- Expansion in length: max. 0.3% according to EN 438-2.17

- Width expansion: max. 0.6 % according to EN 438-2.17

- UV resistance: Excellent

- Weather resistance: Excellent

- Chemical resistance: Excellent

NOTE: You can find full details of the technical data of our HPL sheets in dust grey in the technical data sheet.

- Additional Information

Additional Information

Product-ID 40037C Thickness 6mm - 8mm Standart Length 3050 Standard width 1300 Delivery Time Dispatch within 2-3 working days Plastic High pressure laminate Material HPL UV resistance UV resistant Color Grey Color accuracy Color similar to RAL color system RAL color code RAL7037 Color designation Dusty grey - Reviews

- Attachments