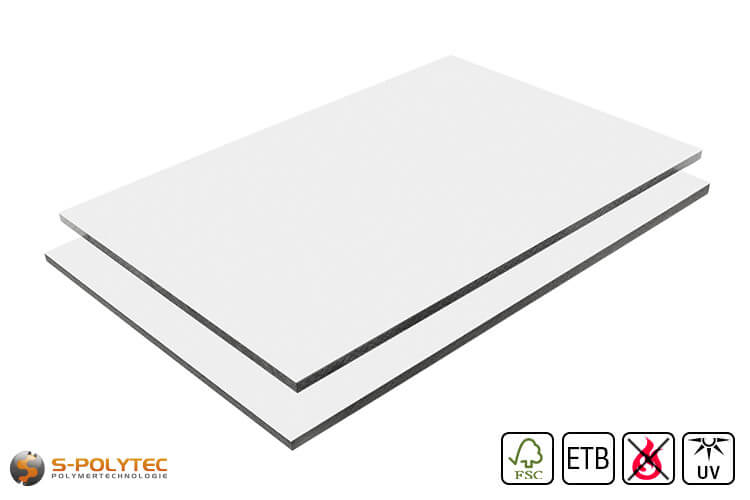

HPL sheets traffic white (RAL9016)

Weatherproof, scratch-resistant HPL sheets cut to size for indoor and outdoor use with surface decor on both sides in traffic white (RAL 9016) in thickness 6mm or 8mm, buy made-to-measure online at low prices.

✓ UV- and weather-resistant

✓ Flame-retardant

✓ ETB balcony approval

✓ FSC-certified

✓ Decor surface on both sides

Note: Larger formats available on request due to increased shipping costs

The item is in stock

Dispatch within 2-3 working days

- Panels in Cut

- Request a sample

Request a free sample.

Dimensions of the samples approx. 200mm x 100mm

- at pieces 0,00 € (Base Price 0,00 € / m2)

- at pieces 0,00 € (Base Price 0,00 € / m2)

- at pieces 0,00 € (Base Price 0,00 € / m2)

All prices include 19% VAT.

0,00 € / pc.

0,0000kg / pc.

All prices include 19% VAT.

- Description

White HPL sheets cut to size according to RAL (RAL 9016, traffic white)

Balcony approval ✓ Weatherproof ✓ Waterproof ✓ Flame-retardant ✓

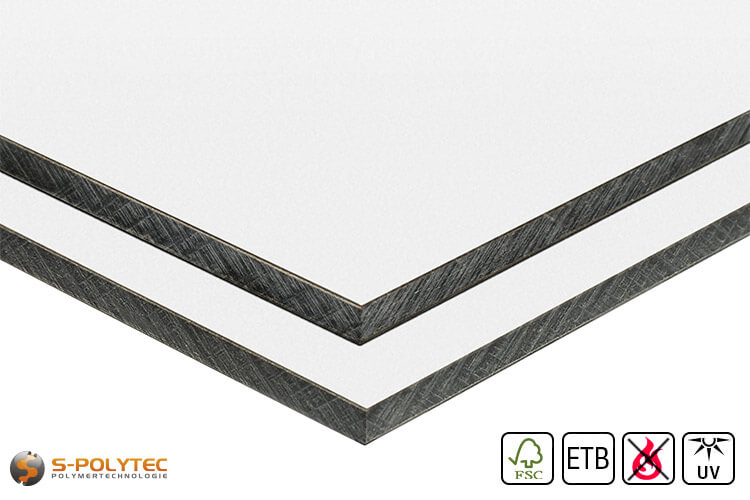

Our HPL panels with a white surface on both sides are available directly in the desired size in the thicknesses 6mm and 8mm at particularly favourable prices. The decorative multi-layer panels made of high-pressure laminate are flame-retardant and comply with the ETB directive. The core of HPL consists of several layers of kraft paper, which is soaked in phenolic resin. The surfaces on both sides consist of white decorative paper dyed according to the RAL colour system and soaked in melamine resin, which is pressed under very high pressure to form a compact HPL panel.

Our white facade panels are UV and weather resistant, so that yellowing of the white surfaces is ruled out even with long-term outdoor use. The non-porous surfaces are insensitive and easy to clean. Our white HPL panels have a protective film on one side. After removing the film, when processing and assembling the panels, make sure not to push them over each other or over an edge in order to avoid damage.

Characteristics of our white HPL panels

Decorative panels made of HPL are highly weather-resistant and therefore ideally suited for outdoor use as privacy panels or facade cladding. HPL panels are lightfast, UV and weather resistant and, as weatherproof cladding panels, defy even the most adverse environmental influences, such as acid rain. The white panels made of high pressure laminate are non-corrosive and insensitive to both heat and frost. The white HPL can be used permanently at temperatures from -30°C to +80°C.

HPL panels are extremely impact-resistant and have a scratch-resistant surface. They have a high mechanical strength and are resistant to bending. These properties are ideal prerequisites if you want to use the white sheets for a balcony edging. Thanks to the fulfilment of requirements according to the ETB guideline for fall protection, this is also possible without any problems. However, not all HPL panels meet this requirement. However, ETB approval is available for our white HPL sheets in 6mm and 8mm thicknesses.

In contrast to the conventional HPL of many other manufacturers, which are classified as normally combustible, our HPL panels in RAL9016 are considered flame retardant according to DIN EN 13501-1 B - s1, d0. This is comparable to the DIN 4102 B1 classification.

HPL panels in white, like all our HPL panels, have a non-porous surface so that they are very easy to clean. For light soiling, cleaning with clear water and clean, soft wipes is sufficient. But even stubborn dirt, such as graffiti, can be removed effortlessly in most cases with organic solvents (Acteon, methylated spirits, etc.).

WARNING: We strongly advise against using abrasive cleaners, scouring pads or polishing agents to clean the surfaces so as not to damage the decorative surfaces.

Approvals and standards for HPL panels in traffic white (RAL 9016)

- Highly flammable according to DIN EN 13501-1 B-s2, d0 (comparable with DIN 4102 B1)

- Balcony approval in accordance with ETB directive "Components that protect against falling"

- Our HPL panels are classified as A+ according to the standard on VOC emissions

- FSC certified (ecologically sustainable and socially responsible forestry)

Our white HPL easily meets the requirements of the standard on VOC emissions and is rated class A+, thus strictly adhering to the strict tolerance values with regard to chemical emissions. This means that it can be used without restriction for interior applications, for example for the construction of furniture, partition walls or complete interior fittings. Furthermore, our FSC-certified HPL boards are considered environmentally friendly. They are free of heavy metals, asbestos or organic halogens (chlorine, fluorine, bromine or sulphur compounds) and are physiologically harmless.

Cutting our white HPL sheets to size - quickly and easily online

We deliver your white HPL sheets directly in your desired size

With us, you can order the white HPL sheets directly online in your desired size at very favourable prices. The panels are cut on one of our modern panel saws for horizontal cutting with a low tolerance of just +/-1mm. This not only saves you time for cutting, but also means that you do not need any special saw blades made of hard metal, which are recommended for sawing the hard multi-layer boards. Simply choose between the available thicknesses of 6mm or 8mm and enter your desired dimensions in millimetres in the input fields. Our cutting configurator will determine your individual, favourable price depending on the information entered and the desired quantity and will automatically take quantity discounts into account.

HPL cuts up to a format of 1500mm length and 1000mm width, optionally in 6mm or 8mm thickness, are possible via the cut configurator. Dimensions beyond this are no longer feasible in standard shipping on pallets, so that higher shipping costs are incurred for larger cuts. In principle, however, we are able to cut HPL panels up to a size of 3050mm x 1300mm from our white panels in stock. For larger formats of our double-sided white HPL sheets, please send us an enquiry by email with all the necessary details (dimensions, thickness, quantity) that we need to prepare a quotation. We will send you your personal, low-priced offer including shipping costs and delivery time as soon as possible.

Application examples for HPL sheets in white

- HPL sheets in white are very often used as privacy screens for balconies

- White HPL sheets are used for large-scale facade cladding of properties

- Fence elements made of white HPL panels ensure a permanent visual protection of your property

- Stair railing cladding with white HPL panels is possible both indoors and outdoors

- and many more

Processing HPL panels in white

Decorative multi-layer panels such as HPL, our panels that are white on both sides, can be cut or processed in a variety of ways. Basically, the processing of HPL panels is equivalent to the processing of hardwood. HPL panels can be cut with carbide saw blades or diamond-tipped saw blades without any problems. Milling HPL panels also requires specially hardened tools made of solid carbide, because conventional milling cutters wear out very quickly due to the high hardness of the material.

For hole drilling, we recommend the use of facade panel drills with a centring point, as no chipping of the drill holes is to be expected here, even if the HPL panel is not resting on a flat surface. If you do not have such a special drill, you can also use a drill made of carbide or an HSS drill instead. In this case, however, the panels should be laid flat on a firm surface to minimise chipping when the drill comes out.

TIP: With our milling service, we can cut the panels to size and drill holes directly with them.

For mounting the white cladding panels on a wooden substructure, we offer rustproof HPL screws in white at particularly favourable graduated prices starting at just one screw. The screws are made of high-quality A4 stainless steel and have a scratch-resistant, UV-resistant head lacquer that matches the colour and gloss level of our white HPL panels exactly.

With the MS Polymer Parabond 600 in white, assembly by gluing is also possible. The strong assembly adhesive has a very high initial adhesion and adheres to almost all non-porous substrates used in the construction sector. Thus, bonding to e.g. concrete, sand-lime brick, plaster, plasterboard or even wood is possible. However, the facade panels should be adequately secured against slipping or falling down until the adhesive has fully cured.

Painting HPL panels is certainly possible, but requires certain preparatory steps and special lacquers, as well as pre-treatment with an appropriate primer. Due to the UV and weather-resistant surface of our HPL panels, however, lacquering is not necessary and does not require regular renewal of the lacquer layers.

NOTE: Our HPL panels are delivered with a protective film on one side, which should be removed after installation at the latest.

Technical data of our HPL sheets in traffic white

- Colour: RAL9016 (Traffic white)

- Thickness: 6mm and 8mm

- Physical density: 1.35 g/cm³

- Modulus of elasticity: min. 9,000 MPa according to EN ISO 178

- Bending strength: min. 80 MPa according to EN ISO 178

- Mass increase: max. 5% according to EN 438-2.15

- Temperature resistance: -30 °C - +80 °C

- Expansion in length: max. 0.3% according to EN 438-2.17

- Width expansion: max. 0.6 % according to EN 438-2.17

- UV resistance: Excellent

- Weather resistance: Excellent

- Chemical resistance: Excellent

NOTE: You can find full details of the technical data of our HPL sheets in traffic white in the technical data sheet.

- Additional Information

Additional Information

Product-ID 40016C Thickness 6mm - 8mm Standart Length 3050 Standard width 1300 Delivery Time Dispatch within 2-3 working days Plastic High pressure laminate Material HPL UV resistance UV resistant Color White Color accuracy Color similar to RAL color system RAL color code RAL9016 Color designation Traffic white - Reviews

- Attachments