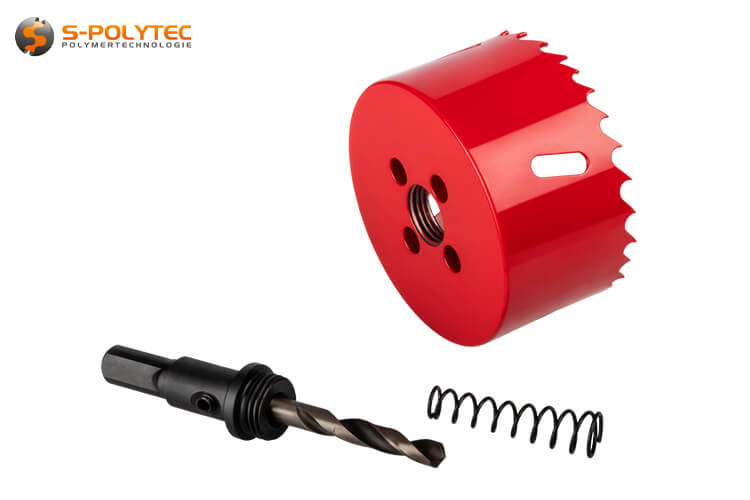

Ø 60mm HSS bi-metal hole saw

Our 60 mm diameter bi-metal hole saw with a secure triangular shank for a tight fit in the drill chuck is suitable for all cordless screwdrivers and drills and has progressive alternating teeth for precise cut-outs in aluminium, wood, plastic and much more.

✓ Made from HSS bimetal

✓ Fast, precise & durable

✓ UNF 5/8 inch thread mount

✓ Incl. HSS-G centre drill bit

✓ Incl. spring ejector

The 60 mm hole saw is ideal for the cut-out for the drainage of our aluminium patio covers.

The item is in stock

Dispatch within 2 - 3 working days

- calculate the price

€6.66 / pc.

0,2300 kg / pc.

All prices include 19% VAT.

- Description

Ø 60mm bi-metal hole saw for wood, plastic & light metal

Cobalt-alloyed steel ✓ Progressive alternating toothing ✓ 32 mm cutting depth ✓

Our 60 mm diameter bi-metal hole saw has a maximum cutting depth of 32 mm. Thanks to the production from a combination of cobalt-alloyed M42 steel and high-speed steel - HSS steel for short - and the alternating toothing, high sharpness and precise cutting performance as well as a very long service life are guaranteed. The hole saw basically consists of four individual components. These include the drill bit with a diameter of 60 mm, the adapter for holding the bits with a UNF 5/8 inch thread, which is very common in hole saws, a replaceable centre drill bit made of profile-ground HSS steel with a diameter of 6 mm and, last but not least, the ejector spring made of robust steel, which ensures easy ejection of the drill core. The adapter's triangular shank ensures a firm hold and can be used in any standard cordless screwdriver or corded drill with a chuck.

Professional quality made of bi-metal with vario-toothing at unbeatable prices.

Originally designed by us for drilling holes for drainage in the drainage channel and the support post of our aluminium patio roofs, the hole saw is also a very useful tool in countless other areas of application and is ideal for a wide range of different materials. Thanks to the progressive alternating toothing, precise cuts are also possible in soft to medium-hard wood, aluminium and other light metals, as well as in insulation boards, drywall panels or plastic panels. With a diameter of 60 mm, the hole saw is ideal for feed-throughs in drywall for drain pipes, supply and exhaust air from air/heat exchanger systems or for installing compact recessed spotlights or cable feed-throughs for TV sets or in desk tops.

Features of the 60 mm bi-metal hole saw

A high-quality hole saw is characterised by high durability and a precise cutting pattern. With the 60 mm hole saw from our own brand, we are focussing on maximum quality and have deliberately opted for a bi-metal that is made up of HSS steel and M42 steel with a cobalt alloy. This combination guarantees very high wear resistance, even under intensive use. The alternating toothing with a tooth spacing of approx. 7 mm saws effortlessly through all suitable materials without jamming. The drilling dust, metal or plastic chips are removed via the large holes in the crown wall, enabling fast, precise hole drilling with significantly less effort. This protects the battery and also allows the use of cordless screwdrivers with a lower torque.

In order to be able to use the hole saw with all commercially available drills and cordless screwdrivers that have a conventional drill chuck, the set includes an adapter that can simply be screwed into the thread of the drill bit. Alternatively, adapters with an SDS-Plus mount can also be screwed into the 5/8" x 18mm thread of the hole saw. This is a very common size for hole saws and diamond core bits in accordance with the UNF standard (unified national finethread). The robust triangular shank with a diameter of 9 mm ensures a secure hold in the drill chuck. This completely prevents the drill chuck from spinning, as can happen with a cylindrical shank, especially when working with hard materials or deeper cuts. An easily accessible grub screw allows the centre drill bit to be changed quickly so that it can be replaced with a new HSS drill bit if necessary. The drill bit can also be customised to the material. All drill bits with a diameter of 6 mm are suitable here. A special drill bit made of solid carbide is particularly recommended for HPL. For drilling holes in wood, however, a wood drill bit with a fine centre point is the better choice.

Advantages of our hole saw with 60 mm diameter

- The bi-metal made from HSS and cobalt-alloyed M42 steel guarantees a long service life

- Perfectly suited for wood, HPL, plastic, aluminium or insulation and drywall panels

- The diameter of 60 mm is suitable for the drainage of our patio roofs

- The hole saw works effortlessly through aluminium until the maximum cutting depth is reached

- Effortless, fast cutting is guaranteed thanks to the progressive Vario interchangeable toothing

- Drilling dust is efficiently removed via lateral slotted holes for less effort

- The triangular shank of the adapter ensures a tight fit in every drill chuck

- The HSS drill bit can be easily replaced with a drill bit suitable for the material

Application and handling of the 60 mm hole saw

We have included the S-Polytec hole saw with a diameter of 60 mm and a cutting depth of 32 mm in our range primarily for drilling drainage holes for our aluminium patio roofs. However, the possible areas of application extend far beyond this, so that the crown can also be used in the heating and sanitary sector for pipe feed-throughs and drains, as well as for cable feed-throughs, for mounting recessed spotlights or fixing ventilation rosettes, for example in heating systems with heat exchangers. Thanks to the high-quality workmanship and choice of materials, the hole saw is suitable for countless materials such as soft and medium-hard types of wood, light metals such as aluminium, magnesium or copper, insulation boards, drywall panels, aerated concrete, HPL panels and many other plastic panels.

Sharp drill bit for precision

To drill a hole in a wall, cabinet or aluminium profile, the centre drill must be positioned at the marked position. With a diameter of 6 mm, this is very suitable for all materials for which the hole saw can be used, even without pre-drilling. Thanks to the profile-ground design made of HSS steel with a point angle of 118°, the drill bit also glides effortlessly through HPL or metal. The length of the drill bit has been selected so that it can be positioned easily without the drill bit of the hole saw obstructing the view. It also provides optimum centring of the drill bit so that it can cut through surfaces without jamming. Thanks to the progressive alternating toothing, wedging is almost impossible even with deep cuts of up to 32 mm.EXPERT TIP: Adapt the centre drill to the material for perfect cut-outs.

Precise, fast & efficient

The hole saw is designed for maximum precision, efficiency and durability. In addition to the Vario toothing, the decisive factors are the slotted holes in the crown wall, which ensure the rapid removal of drilling dust, the generous 9 mm triangular shank for a firm fit in the drill chuck and the replaceable centre drill bit. This allows the hole saw to be positioned precisely and work effortlessly through all suitable materials. Thanks to the cooling effect of the side holes, the hole saw heats up less quickly, meaning slightly higher speeds are possible compared to a closed design. The smooth movement of the saw blade also reduces heat generation and reduces the effort required to drill circular cut-outs, so that cordless screwdrivers with a lower torque are also suitable.Easy ejection thanks to steel spring

Especially when several cut-outs are to be made in succession, which is not uncommon when installing recessed spotlights in the ceiling, it is important to eject the drill core quickly so that work can be carried out without major delays. A sturdy steel spring is used for this purpose, but it can also be removed very easily. This is particularly useful when drilling holes at greater cutting depths, for example in a kitchen worktop or a thicker furniture side panel. Even in such cases, the circular cut-out can be easily removed from the drill bit using simple tools. A simple screwdriver can be used as a lever to remove the core from the drill bit through the elongated holes on the side.Technical data of the bi-metal hole saw

- Product type: Hole saw

- Hole saw material: Bi-metal (HSS steel, cobalt-alloyed M42 steel)

- Drill material: HSS

- Ø hole saw: 60mm

- Ø Drill: 6,0mm

- Length Drill: Round

- Interlocking: Coarse, alternating toothing

- Tooth spacing: approx. 7mm

- Cutting depth: 32mm

- Direction of rotation: Clockwise rotation

- Mounting thread: 5/8" x 18 UNF

- Mounting shaft: Ø 9mm (Triangular shaft)

- Drill holder: Ø 6mm (Round shaft)

- Ejector: Yes, removable steel spring

- Suitable materials: Plasterboard, HPL, wood, light metal, plastic

- Additional Information

Additional Information

Product-ID LS-BM-60 Delivery Time Dispatch within 2 - 3 working days EAN/GTIN 4260604222819 Material Bi-Metall (HSS-Stahl, Cobalt-legierter M42-Stahl) Property Ø 60mm (Progressive Wechselverzahnung) Weight 0.2300 - Reviews