90° angle bracket for construction profiles

The 90° mounting brackets made of corrosion-resistant die-cast aluminium with slot bridge for right-angled connections of construction profiles with open slots and ideal for struts or extensions of existing constructions.

✓ Corrosion-resistant aluminium

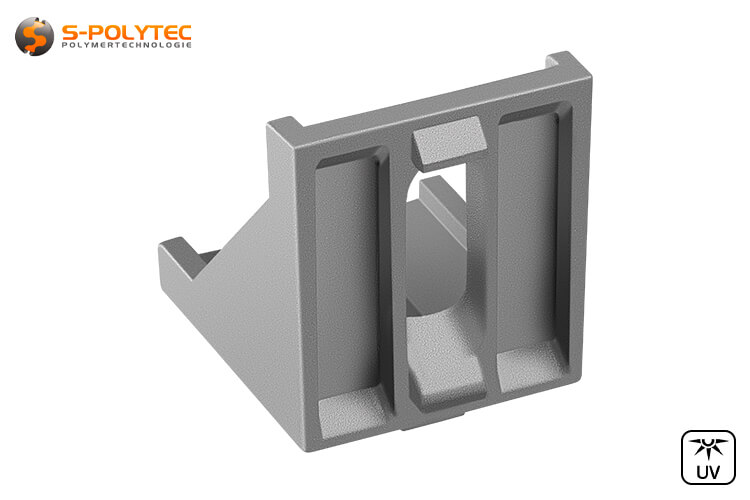

✓ Anti-twist thanks to the groove web

✓ Ideal for cap screws

✓ Simple profile connection

✓ Lateral reinforcement

✓ For indoor and outdoor use

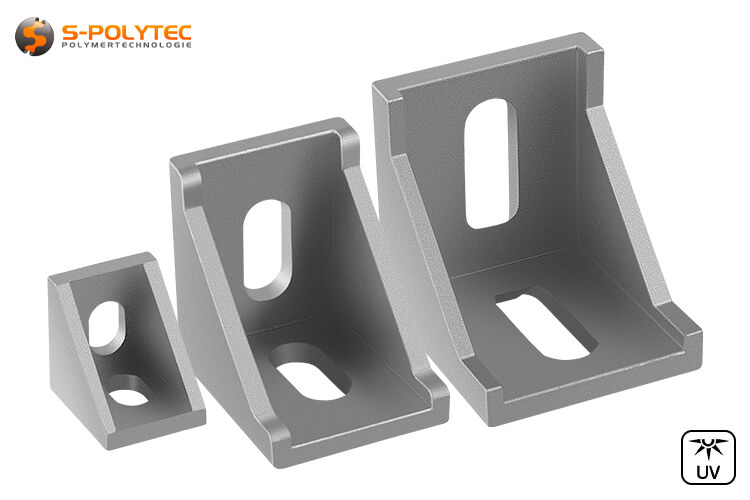

The 90° angle profile connectors for construction profiles are available in three different sizes.

The item is in stock

Dispatch within 2-3 working days

- calculate the price

- from 10 Items €1.36/ pc. (Base Price €1.36/ pc.)

- from 20 Items €1.32/ pc. (Base Price €1.32/ pc.)

- from 50 Items €1.29/ pc. (Base Price €1.29/ pc.)

All prices include 19% VAT.

0,00 € / pc.

0,0000 kg / pc.

All prices include 19% VAT.

- Description

90° angle bracket for construction profiles

Rustproof die-cast aluminium ✓ Easy to assemble ✓ Different sizes ✓

Our 90° silver mounting brackets are available in three different sizes from 20mm to 40mm. They are used to connect construction profiles that are to be arranged at right angles to each other. The width is actually slightly smaller. The connectors fit flush with the rounded corners. Two grooved webs hold the profile connectors securely in position, preventing them from twisting under load. Thanks to the die-cast aluminium manufacturing process, the connectors not only offer excellent stability, but are equally suitable for indoor constructions and for outdoor applications exposed to the weather due to their very good corrosion resistance.

The high-quality angle connectors are compatible with all profile systems that have at least one open groove along the profile. It does not matter whether they are I-type profiles with rounded corners like the item®-construction profiles or the angular variant of the B-type, for example the Bosch®-system profiles. Only the choice of assembly material has to be adapted to the existing groove.

NOTE: To mount the angle bracket on construction profiles, two slot grooves with cylinder head screws or hammer head screws with grooves are required. These are available in different versions for construction profiles with 6mm or 8mm slot width and can be ordered in any quantity as needed.

Properties of our 90° mounting brackets made of die-cast aluminium

Our angle connectors for connecting profiles at a right angle are available in three sizes for profiles with a width of 20mm, 30mm and 40mm. Even though we usually talk about 20mm mounting brackets, these are slightly narrower at 18mm. This ensures that the edge does not protrude in the case of rounded profiles and is flush with the flat surface of the construction profile. The same applies to the larger versions of our angle connectors. Both mounting sides are each provided with two slot webs to ensure a stable and torsion-proof screw connection of the profiles. Those can withstand even mechanical loads. However, for constructions that are subject to high loads due to weight or movement, we recommend the use of the larger mounting brackets with reinforcement for particularly stable angle connections. Our 90° angles are made of die-cast aluminium, which combines low weight with very good stability. Die-cast aluminium offers excellent strength and rigidity, making these components ideal for structural applications. It has a reason that die-cast aluminium is used for a wide range of applications in various industries, including automotive, aerospace, electronics and mechanical engineering. Another important aspect is the excellent corrosion resistance, which makes it suitable for outdoor use, especially when the structures are to be used for roofing, patio furniture, storage systems or trailer conversions, for example.

Installation is done with screws and slot grooves. For this purpose, the angle connectors have elongated holes on both sides, the size of which depends on the size of the connector. The elongated hole makes it easier to precisely install the construction profiles. For the small version of the mounting bracket, we recommend cylinder head screws with an M4 thread and matching slot nuts. For the two larger variants, screws with a thread diameter of 6mm are perfectly suitable. For the large angle bracket 8mm screws can also be used but this requires slot nuts with an 8mm internal thread. We only offer those in the version with a spring ball, which has to be inserted into the slot profile from one side and cannot be inserted at any point through the open slot into the profile.

NOTE: Countersunk head screws are unsuitable for mounting, as they do not make full contact with the surface and thus cannot guarantee adequate load distribution of the screw connection.

Specific data for the 90° fixing bracket

- 90° mounting bracket 20x20mm: Dimensions (WxDxH): approx. 19mm x 26mm x 26mm, Ø hole: 6.25 x 10.50mm, weight: 12g

- 90° mounting bracket 30x30mm: Dimensions (WxDxH): approx. 27 mm x 35mm x 35mm, Ø hole: 7.25 x 16.50mm, weight: 20g

- 90° mounting bracket 40x40mm: Dimensions (WxDxH): approx. 35mm x 40mm x 40mm, Ø hole: 9.00 x 21.50mm, weight: 22g

Installation and use of angle connectors

The most common way of mounting profiles with 90° angle connectors is to use slot grooves and socket head screws, which requires a suitable Inbus® key. First, the slot groove is inserted into the profile with the screw and turned 90 degrees so that it is wedged in the profile groove. Then, remove the screw from the slot groove, place the washer on it, thread it through the slot of the angle connector and screw it into the slot groove‘s thread. It is advisable not to tighten the screw completely yet, to make it easier to position the second profile. A slot nut must also be inserted into the profile, a second screw screwed through the connector and into the slot groove. A slot groove with a spring ball can be used to prevent the slot nut from slipping. Alternatively, the slot groove can also be pre-assembled to some extent on the mounting bracket. This makes it easier to insert it into the slot and is much easier, especially for vertical installations with slot nuts.

The mounting brackets are ideal for stable and resilient constructions and, in contrast to the internal corner connectors, have the advantage that they can be attached to the construction profile or removed again at any time. This is a particularly positive aspect when expanding existing constructions if the outside of the affected profile is no longer freely accessible and an internal connector can therefore no longer be inserted into the groove.

NOTE: The mounting brackets are equipped with two groove webs on each of the two mounting surfaces to ensure that the profiles are mounted in a torsion-proof manner. This means that the connectors can only be mounted with the groove and cannot be twisted onto the profiles or even attached to the wall. For such applications, we offer profile connectors with a half-round design on one side without groove webs.

The compact profile connectors are excellent for adding an intermediate shelf to shelving systems made of construction profiles. This could be a home shelf. It could also be a construction for an open wardrobe in a dressing room, where the shelves are made of attractive HPL panels. Furthermore, the brackets can be used to quickly mount additional struts to a construction, for example to increase the stability of a machine construction with higher mechanical loads. However, it is not necessary to connect two identical profiles. It is even possible to use the connectors to mount objects to a construction profile, although it should be noted that the slot bars may interfere.

Examples of how our flange nuts are used

- Brackets are ideal for intermediate struts and for reinforcing existing structures

- The angles are perfect for adding intermediate shelves to shelving systems made of construction profiles

- To combine construction profiles of different sizes, angle connectors are the best choice

- Angle connectors can also be used as eyelets for hooks on coat racks made of profiles

- The brackets can also be used to attach wooden posts to construction profiles

Technical data of the 90° mounting bracket

- Material: Aluminium die casting

- Colour: Silver

- Angle: 90°

- Height: 20mm up to 40mm

- Width: 18mm up to 35mm

- Mounting holes: Slot hole

- Ø Hole drilling: 6.25 x 10.50mm up to 9.00 x 21.50mm

- Weight: 12g - 22g

- UV-resistance: Excellent

- Weather resistance: Excellent

- Corrosion resistance: Excellent

- Additional Information

Additional Information

Product-ID BFW-90-0000 Delivery Time Dispatch within 2-3 working days Property 90° angle bracket for construction profiles Material Aluminium Color Silver - Reviews

You may also be interested in the following product(s)

Aluminium construction profile 20x20, groove 6 silver (anodised)

Aluminium construction profile 30x30, groove 8 silver (anodised)

Aluminium construction profile 40x40, groove 8, silver (anodised)

Corner connector for construction profiles (internal)

Slot nuts for construction profiles

Hammer screws for construction profiles