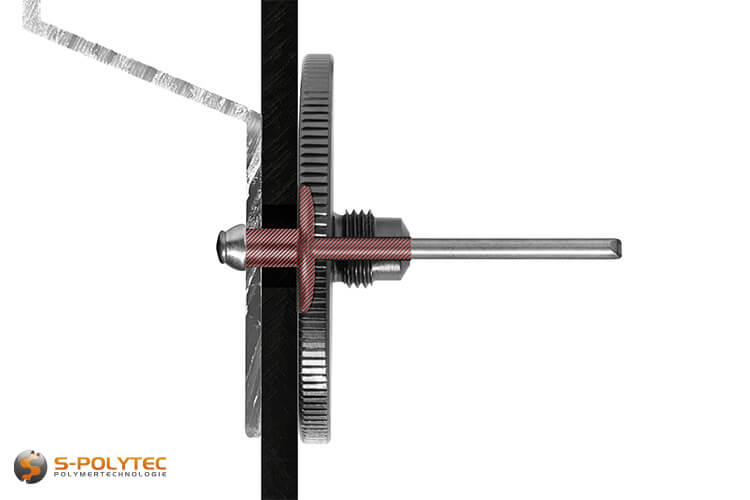

Special gauge mouthpiece ALU-16

The special gauge mouthpiece ALU-16 is suitable for the constraint-free installation of aluminium composite panels with our aluminium facade rivets with a head diameter of 16mm and always ensures the perfect gap distance.

✓ For aluminium composites

✓ For Ø 16mm aluminium facade rivets

✓ Suitable for sliding point mounting

✓ Automatic gap distance

✓ Generous support service

✓ M10 threaded receptable

The nose piece for aluminium composites can be used with all commercially available riveting pliers with M10 thread receptacle.

The item is in stock

Dispatch within 2-3 working days

- calculate the price

€59.95 / pc.

0,0600 kg / pc.

All prices include 19% VAT.

- Description

Special gauge mouthpiece ALU-16 for aluminium composite panels

For Ø 16mm facade rivets made of aluminium ✓ For sliding point mounting ✓

Our special gauge mouthpiece type ALU-16 is suitable for the sliding point assembly of aluminium composite panels with our high-quality aluminium facade rivets. Thanks to the thread size of M10x1, the mouthpiece can be easily screwed into the thread receptacle of all commercially available riveting tongs. Whether it is a hand-operated riveting gun, an electric riveting tool or a pneumatic riveting gun operated with air pressure, it is irrelevant for the use of the mouthpiece.

The generous contact surface helps to ensure that the surfaces of the aluminium composite panels are not damaged when the rivet mandrel is pulled in. The shape and size of the recess in the contact surface is perfectly matched to our large-head aluminium rivets. In order to ensure constraint-free installation, as is absolutely necessary for façade cladding with aluminium composite materials, the geometry of the special gauge mouthpiece is defined in such a way that a safety distance of approx. 0.3mm between the panel surface and the rivet head is ensured.

Scope of delivery:

- 1 x special gauge mouthpiece type ALU-16

NOTE: For the use of the special gauge mouthpiece, a standard riveting pliers with M10 thread receptacle is required.

Technical data of the special gauge mouthpiece type ALU-16

- Name: Type ALU-16

- Material: Hardened steel

- Ø Mounting thread: M10

- Ø Mouth piece: ca. 49mm

- Ø Rivet head: 16,0mm

- Ø Rivet shaft: 5,0mm

- Material rivet: : Aluminium

- Mounting type: Slide point assembly

- Gap distance: ca. 0,3mm

- Building materials: Aluminium composite panels

Application restrictions for the special gauge mouthpiece ALU-16

Special gauge mouthpieces are used for the constraint-free assembly of façade panels with façade rivets that are to be riveted with riveting pliers. The mouthpieces are specially adapted to the materials so that they can only be used for these.

Our special gauge mouthpiece type ALU-16 is suitable for mounting aluminium composite materials, such as our aluminium composite panels. In addition, aluminium composite panels of other brands, e.g. Alu Dibond, Alu Cobond, Dilite, etc. can also be processed without any problems. However, the special gauge mouthpiece cannot be used for solid plastics, as well as laminate panels made of HPL or fibre cement.

Another application restriction concerns the type of facade rivets that can be riveted with the nose piece. The type ALU-16 is only suitable for our aluminium facade rivets with a head diameter of 16mm and a sleeve diameter of 5mm. However, it does not matter whether the rivets are head-painted rivets in RAL colour or have an unpainted head. The length of the rivet sleeve, which defines the clamping area of the rivet, is also irrelevant.

Application instructions for the special gauge mouthpiece ALU-16

In order to use the mouthpiece, it must simply be screwed into the threaded receptacle provided for this purpose on the riveting tool.

The special gauge mouthpiece is designed for riveting sliding points when mounting aluminium composite panels on substructure profiles made of aluminium. This means that the holes in the substructure profiles must be drilled with a diameter of 5.1mm and the holes inside the cladding panels with a diameter of 8mm or 10mm. One hole per cladding panel, however, must be defined as a fixed point, where the panel hole must also be drilled with a drill diameter of 5.1mm. We recommend removing any burrs in the holes with a hand taper countersink or round deburrer before placing the rivets.

Once all the holes have been drilled in the desired positions and the fixed point has been defined accordingly, the remaining facade rivets can be placed as sliding points by inserting the rivet sleeve through the panel into the holes in the substructure. Finally, the special gauge mouthpiece can be applied in such a way that the rivet mandrel of the facade rivet is inserted through the feed-through provided in the centre of the mouthpiece until the contact surface rests fully on the plate. By operating the riveting gun, the mandrel is pulled in until it breaks off when the predefined tightening torque is reached. The gap distance, which is important for sliding points, is always maintained by the special geometry of our ALU-16 nose piece, which allows the components to be moved against each other as required after the riveted joint.

Thanks to the large, smooth contact surface of the special gauge mouthpiece for aluminium composite panels, damage to the sensitive surface is effectively avoided. This surface should be checked for damage and cleaned of dirt and impurities before each use. Otherwise, adhesions can be pressed into the thin cover layers of aluminium.

NOTE: Before installing the facade rivets with the special gauge mouthpiece, the protective film must be removed from the affected areas.

- Additional Information

Additional Information

Product-ID AFN-SLM-AG16 Delivery Time Dispatch within 2-3 working days EAN/GTIN 4260604223762 Material hardened steel Weight 0.0600 - Reviews