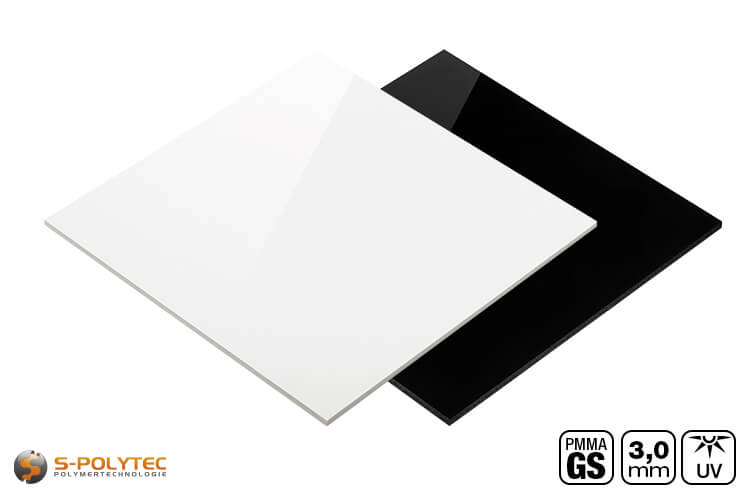

Opaque GS cut to size (opaque)

Our opaque acrylic glass GS cut to size is opaque and almost opaque despite its low thickness. The glossy sheets of cast acrylic glass are weatherproof and waterproof and can therefore be used indoors and outdoors without hesitation.

✓ Opaque, opaque finish

✓ Almost opaque

✓ UV- and weather resistant

✓ Enormously resistant to ageing

✓ High surface gloss

The opaque acrylic glass panels are available in the colours black or white with a thickness of 3mm, cut to size to the millimetre.

The item is in stock

Dispatch within 2-3 working days

- Panels in Cut

- at pieces 0,00 € (Base Price 0,00 € / m2)

- at pieces 0,00 € (Base Price 0,00 € / m2)

- at pieces 0,00 € (Base Price 0,00 € / m2)

All prices include 19% VAT.

0,00 € / pc.

0,0000kg / pc.

All prices include 19% VAT.

- Description

Buy opaque acrylic glass GS cut to size online

UV- & Weather resistant ✓ Enormously resistant to ageing ✓ Opaque✓

We offer the opaque sheets of acrylic glass GS cut to size with a thickness of 3mm, optionally in black or white in the size of your choice at favourable prices. The solid sheets are not transparent, but opaque and therefore have a barely noticeable light transmission of no more than 5%. Acrylic glass GS is characterised by very good UV and weather resistance, as well as enormous resistance to ageing. The uniform colouring of the solid sheets in black or white ensures that cut edges and surfaces have the identical colour. The hard surface typical of acrylic glass is comparatively insensitive to scratching and has a high gloss level. Casting the sheets creates surfaces with outstanding surface quality. These are protected from impacts and scratches on both sides by a robust, easily removable protective film.

We offer the opaque acrylic sheets online in millimetre-precise cut to size at favourable prices. Very small cuts from 30mmx30mm are already possible. The largest format in which we offer the acrylic glass cuts online is 1500mmx1000mm. Larger formats are possible on request up to a size of 3050mm x 2030mm. The cutting is done with a modern CNC panel saw with a low sawing tolerance of 1mm. Due to the sawing process, the rough cut edges appear matt and not polished as with laser cutting.

Properties of the opaque acrylic glass GS cut to size

Acrylic GS is cast and not extruded. This means that no stresses occur inside the sheet during production, so that the risk of stress cracks during laser cutting or bonding is greatly reduced. Due to the very high pigmentation, an opaque, evenly coloured sheet with an outstanding surface quality is produced during casting. Opaque means that you cannot see through the sheets, which is why the opaque acrylic sheets are perfect as privacy screens or for wall and furniture cladding. However, due to the sheet thickness of 3mm, the sheets are not completely opaque, so that a very small amount of light can still be perceived through the sheet when strong light sources are used. The lighter the panel, the higher the light transmission, which decreases significantly with increasing panel thickness. The highest light transmission is given with white panels and is still approx. 5% with a 3 mm panel.

- Acrylic GS White:similar to RAL9010 (pure white), opaque, light transmission approx. 5%

- Acrylic GS Black:similar to RAL9005 (jet black), opaque, light transmission approx. 1%

Acrylic sheets can be used for indoor and outdoor applications. PMMA absorbs only extremely small amounts of water and, with a water absorption of 0.3% in 24 hours (0.5% in 8 days), is one of the water-resistant plastics. Acrylic glass is also very well suited for outdoor use in terms of UV and weather resistance. The weather resistance of cast acrylic is even a little better than the already very good resistance of extruded acrylic. Fading of the black sheets, as well as yellowing of the white sheets, is therefore not to be feared, even after years of use under continuous UV exposure. Ideal conditions for using the opaque acrylic glass cuts for cladding or as privacy screens in the open.

Application examples for acrylic glass in opaque

The opaque acrylic sheets are opaque and, despite the low sheet thickness, are considered opaque due to the very low light transmission. This makes the sheets ideal for light and privacy protection both indoors and outdoors. From privacy screens between balconies, cladding of roller shutter boxes indoors and outdoors, or as decorative fence elements, the opaque sheets provide a high-quality look thanks to their glossy surface.

Acrylic glass is convincing due to its scratch-resistant surfaces with a high gloss and is therefore often used to enhance furnishings such as shelves, cupboard doors and table tops. Due to the opaque design of the sheets, the grain, colours and patterns of the underlying surfaces are concealed. Even scratches, marks and damage on old furniture or in tile mirrors do not shine through the opaque panels and enhance them visually in a simple and cost-effective way.

As a waterproof sheet, acrylic glass can also be used excellently in damp rooms, for example in the bathroom as a shower back panel or wall covering above the bathtub. By combining plain white sheets with coloured, transparent sheets or our black sheets, there are no limits to creativity when designing the bathroom.

- White acrylic glass GS is used as a carrier plate for direct prints and offers a great surface sheen

- Opaque acrylic glass in black or white is popular as decorative cladding for walls, shelves or cabinets

- Opaque acrylic glass is ideal as a tile backsplash replacement without the joints showing through

- Acrylic glass is waterproof and therefore perfect as a shower back panel or for wall cladding in the bathroom and WC

- Thanks to the glossy surfaces, the opaque acrylic is used for decorative trade fair and shop designs

- The glossy panels are suitable as privacy screens for balconies, fence elements or cladding in outdoor areas

- and many more

Processing of cast acrylic sheets

Acrylic glass is a thermoplastic with a high surface hardness that can be processed in many ways. Machining, laser cutting or engraving are among the most common methods for PMMA. Printing, labelling or gluing is also possible with acrylic glass.

Acrylic glass GS cutting and drilling

Our acrylic glass blanks are delivered cut to the millimetre, so that no further cutting is usually necessary. Nevertheless, the material is very easy to saw. If the sheet is placed firmly on a base and a saw blade with medium-density toothing is used, cuts and cut-outs should succeed without any problems. It should be noted, however, that the rotation or stroke speed of the saw must be reduced so that the saw blade does not get too hot and the chip melts into the cut edge. The same applies to all other chip-removing processing methods, such as milling. A low speed, reduced feed and a suitable milling insert, lead to the best result without running the risk of breaking the panel or the tool heating up too much.

Drilling requires a little more care with acrylic glass due to the hard surface and brittleness of the material. If the plate rests firmly on a surface so that it does not flutter or vibrate during drilling, it can be drilled quite well with standard HSS drills. No pressure should be exerted on the drill, otherwise the board may splinter or even break when the drill comes out. As with sawing and milling, care must also be taken when drilling that the drill does not get too hot. The best way to achieve this is to significantly reduce the speed of the cordless screwdriver. With a HK drill for plastics, specially designed for drilling brittle plastic sheets, including acrylic and Plexiglas sheets, the risk of heat development is much less of a problem due to the elongated drill spiral. The sharp drill tip with a very narrow point angle glides much more easily and precisely through the hard surface, so that absolutely round, precise drill holes are guaranteed.

During machining processes such as drilling, milling or sawing, the edges appear dull and cloudy. These can be smoothed by repeated sanding with a sanding block or sandpaper in increasingly finer grit sizes and finally polished with a special acrylic and polished with Plexiglas polishing paste, such as our PMMApolishto a sheen that approaches the gloss level of the surfaces. Alternatively, the rough edges can also be flamed, but extreme caution is required here, because acrylic glass can also burn during flame polishing if the gas burner remains on one spot for too long.

Acrylic glass can also be cut with a CO² laser instead of sawing or milling. The advantage of laser cutting is that individual contours, cut-outs and circular holes can be made with very high dimensional accuracy. The non-contact laser cutting also means that there is no risk of the sheet breaking during processing or of the edges splintering. Another aspect that speaks in favour of laser cutting is the quality of the cut edge, which appears evenly smooth, almost polished with laser cutting, instead of rough, cloudy as with machining methods.

Acrylic glass GS printing, lacquering and foiling

The white acrylic glass sheets are perfectly suited for use as wall decoration. Many online printers offer the high-quality material with the high-gloss surface for direct printing with a desired motif. In contrast to transparent acrylic glass sheets, however, printing is not done on the back, but directly on the surface. The print on the front is often protected from UV radiation and damage by another transparent acrylic glass plate of the same size.

The black acrylic glass plates are not suitable for direct printing. However, this is not because this will not succeed, but simply because the print can hardly be seen on the black surface. Both sheets are equally well suited for sticking on with a digital print, as well as lettering with a foil plotter or even varnishing.

Glue and seal acrylic glass GS

The coloured acrylic glass sheets can be bonded excellently to each other as well as to many other plastics. With our Acrylic and Plexiglas®glue PMMAprofi, we offer an inexpensive special adhesive that permanently and securely bonds plastics together using the cold welding method. Due to the aqueous viscosity, the adhesive creeps into every finest gap. The so-called annealing process can be dispensed with for cast acrylic glass, because due to the complex process for producing the opaque sheets, the sheets are free of internal stresses and there is no need to worry about stress cracks caused by contact with solvents.

If acrylic glass is glued to tiles, masonry or plasterboard as a kitchen backsplash or shower wall, a strong assembly adhesive is the right choice, because solvent adhesives are suitable for plastics but cannot dissolve building materials such as wood, plaster or stone. With our MS polymer Parabond 600, which we also stock in black and white, it is possible to bond the panels securely to almost all substrates. This adhesive and sealant is also very suitable for gluing the high-gloss panels to furniture or for gluing the panels to the ceiling.

Cleaning acrylic glass GS

Acrylic glass is characterised by a high surface hardness and is therefore not as prone to scratching as most other plastics. Nevertheless, when cleaning the high-gloss surfaces, please note that they should only be cleaned with a soft, lint-free cloth. Solvent-based plastic cleaners or harsh household cleaners containing alcohol should also be avoided, as these can attack the acrylic glass. Use a mild soap solution or a special acrylic glass cleaner, such as our PMMAclean with an antistatic effect, the cleaning of acrylic glass sheets, on the other hand, is problem-free.

NOTE: Like all acrylic sheets in the shop, our opaque acrylic blanks are covered on both sides with a protective film that protects the surfaces from scratches that could occur before or during processing. This film can be easily removed. Depending on the type of processing, the film must be removed beforehand. This includes, for example, printing, gluing, bonding, laser cutting or engraving.

- Additional Information

Additional Information

Product-ID 51500C Thickness 3 Delivery Time Dispatch within 2-3 working days Plastic Acrylglas Material PMMA Standard width 1500 Standart Length 1000 Fire behaviour Normal flammability UV resistance UV resistant Color No Color accuracy Color similar to RAL color system - Reviews

You may also be interested in the following product(s)

Acrylic adhesive - S-Polybond PMMAprofi 100ml

S-Polybond PMMAclean - Acrylic and plexiglass cleaner 500ml

S-Polybond PMMApolitur - Acrylic and plexiglas polishing paste 150ml

HSS-G Drill Type HK for Plastics

Transparent acrylic glass GS cut to size (colourless)

Coloured acrylic glass GS cut to size (transparent)