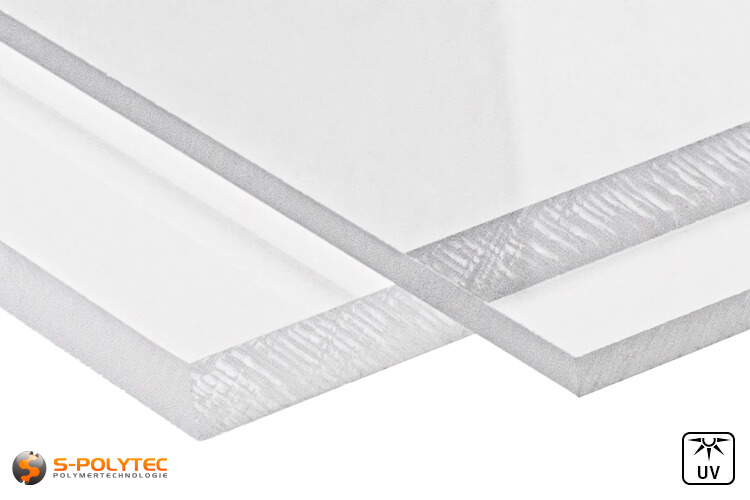

Polycarbonate sheets transparent custom cut (UV-stabilised)

PC (polycarbonate) sheets transparent from 3mm to 8mm thickness. To calculate the prices, enter the length and the width in the corresponding cells under this text in mm. Please note that our cutting configurator calculates the prices depending on the quantity and your cutting.

The item is in stock

Dispatch within 2-3 working days

- Panels in Cut

- Request a sample

Request up to three free samples.

Dimensions of the samples approx. 200mm x 100mm

- at pieces 0,00 € (Base Price 0,00 € / m2)

- at pieces 0,00 € (Base Price 0,00 € / m2)

- at pieces 0,00 € (Base Price 0,00 € / m2)

All prices include 19% VAT.

0,00 € / pc.

0,0000kg / pc.

All prices include 19% VAT.

- Description

Polycarbonate in transparent - impact resistant and shatterproof

Polycarbonate is a thermoplastic amorphous polymer that is formed by polycondensation of bisphenol A and phosgene. Phosgene is an extremely toxic gas. However, it is converted during the chain reaction and forms the carbonate function, so that there is absolutely no danger from the polymer polycarbonate. The carbonate function with neighbouring aromatic ring systems ensures enormous rigidity in the molecule and passes this property on to the polymer. The three oxygens of the carbonate are covalently bonded to the carbon atom and thus create very strong polarity in the molecule. Therefore, polycarbonate is polar and can be dissolved in polar solvents such as acetone. But it is also for this very reason that PC is easy to bond. Polycarbonate is known in Europe under the brand names MAKROLON (BAYER AG) or LEXAN (SABIC).

Although this plastic has been known since 1953 and has been produced industrially for a long time, polycarbonate is still offered to opticians as a new high-tech plastic. This is probably the only way to explain the prices of polycarbonate lenses.

Properties of transparent polycarbonate

The main properties of polycarbonate are good impact resistance, high temperature resistance up to 100°C (short-term up to 120°C) and good transparency. Polycarbonate is not UV and weather resistant by nature, but can be made more so by adding stabilisers or UV-protective coatings.

Physical properties of polycarbonate

The density of polycarbonate is 1.2g/cm³, which is slightly higher than standard plastics.

Due to its polarity, polycarbonate absorbs moisture up to 0.15% of its weight, and unfortunately extremely quickly. Moisture absorption is very strong during thermoforming. The deformation of moist polycarbonate sheets results in a surface covered with blisters. For thermoforming, it is recommended to place a drying oven on the machine and insert the material directly from the drying oven under the stentor frame and form it.

Polycarbonate can be edged when cold. The bends do not crack and the bending remains without deformation. We advise you to edge the sheets with the protective film to minimise damage during processing.

Optical properties of transparent polycarbonate

The light transmission is somewhat lower than with acrylic glass and is 88% with a wall thickness of 3mm. However, this property is not visible to the eye and the sheets appear completely transparent.

Polycarbonate has quite high birefringence and this is strongly influenced by the residual stresses in the material. For some optical applications, this property can be very disturbing. A remedy is to use plastics such as COC, COP or PMMA. Further information on birefringence in polycarbonate can be found in the book by the founder of S-Polytec Andreas Schröder " Untersuchung der Doppelbrechung an Kunststoffoptiken: Fundamentals and Practical Findings".

Polycarbonate sheets and cutting

The polycarbonate sheets are available in thicknesses of 1 - 8mm in formats of 3050x2050mm. In our online shop we offer sheets up to 2x1 metre. The reason for this is the shipping costs, which increase considerably for larger sheets. However, we are happy to offer you individual formats larger than 2x1 metres on request. Our polycarbonate sheets are protected against scratches with a protective film on both sides and have UV protection on both sides.

Our service does not end with the individual cutting. Through large format milling centres we can CNC mill the polycarbonate sheets according to your wishes up to 3x2 metres. Send us your drawing or DXF data with the quantity details and we will certainly prepare an interesting offer for you.

Application examples of polycarbonate sheets

Polycarbonate is used in most cases as shatterproof glazing. It does not break or shatter even at low temperatures, making it the number one choice for a variety of applications. Below we list just a few applications:

Mechanical Engineering

In mechanical engineering, machine and apparatus enclosures are made of polycarbonate. Especially moving parts that can loosen and pose a danger to workers can be caught by polycarbonate without the glazing breaking immediately.

Unbreakable building material

Polycarbonate is considered to be a shatterproof building material and the decisive advantage for construction lies in the fire behaviour of this plastic. Polycarbonate meets the fire standard ISO EN 13501-1 in thicknesses of 1 - 6mm, depending on the type.

- Additional Information

Additional Information

Product-ID POLYCARBONAT Thickness 3-8mm Standart Length 3050 Standard width 2050 Delivery Time Dispatch within 2-3 working days Plastic Polycarbonate Material PC UV resistance UV stabilized Color Colorless Color accuracy No Color designation Transparent - Reviews

- Attachments