Phillips-Bits (single)

The Phillips®-bit for screws with Phillips® drive is made of S2 steel for maximum service life and is available in the three drive sizes PH1, PH2 and PH3 at particularly attractive graduated prices.

✓ High-quality S2 steel

✓ Magnetisable version

✓ ¼ inch drive (6.35mm)

✓ Secure hold thanks to C-notch

✓ Optimum service life

The bits with Phillips®-drives are suitable for bit holders with ¼ inch hexagon socket.

The item is in stock

Dispatch within 2-3 working days

- calculate the price

- from 10 Items €2.00/ pc. (Base Price €2.00/ pc.)

- from 50 Items €1.50/ pc. (Base Price €1.50/ pc.)

- from 100 Items €1.00/ pc. (Base Price €1.00/ pc.)

All prices include 19% VAT.

0,00 € / pc.

0,0000 kg / pc.

All prices include 19% VAT.

- Description

Phillips®-bits made from high-quality S2 steel

From 1 piece ✓ Attractive quantity discounts ✓ ¼ inch drive ✓

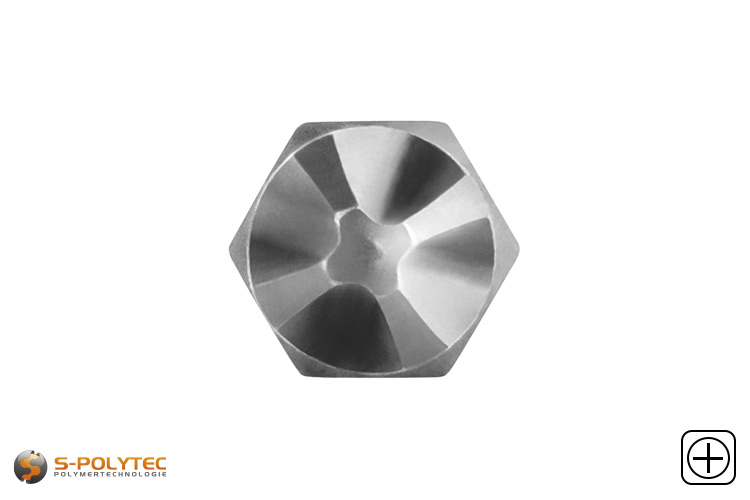

Our Phillips®-bits are available in the three sizes of PH1, PH2 and PH3 at particularly attractive graduated prices. Thanks to the standard bit holder with a standardised bit size of ¼ inches (equivalent to 6.35 mm), the bits can be used in all commercially available bit holders. The hexagonal shape also allows the bit to be inserted directly into the chuck of a drill or cordless screwdriver without a bit holder. The total length of the bits is 25 mm.

A screwdriver bit must have a good, secure fit in the bit holder so that it does not get stuck in the screw drive after screwing in screws, which is not only annoying, but also takes more time if the bit has to be reinserted into the holder each time. Our high-quality Phillips®-bits all have a C-ring notch which, with the appropriate bit holders, ensures that the bit remains securely and permanently in the holder. In addition, the bits made from S2 tool steel can be magnetised, making it easier to position most steel screws without them falling off the bit when placed on the surface.

We offer you the opportunity to use the Phillips®-bits to buy in any quantity. So if you just want to replace a worn bit in your bit range, you've come to the right place. And if you use Phillips®-bits to process screws in large quantities, you benefit from generous quantity discounts on our Phillips® head bits.

Scope of delivery:

- 1xPhillips® bit in selected size

NOTE: With Phillips®-screws, there is a risk that the drive will be turned round and the screw cannot be screwed in any further if the bit is already too worn. Therefore, a Phillips®-bit must be replaced with a new one in the event of damage or severe signs of wear.

Features of our bit inserts with Phillips drive

The quality of a screwdriver bit is reflected in its durability and the gentle processing of screws. For our bits with Phillips® drive, we therefore rely exclusively on high-quality S2 tool steel, which is characterised by its standardised stability. In contrast to many cheap products from the far East, the profile milling of the bits is extremely precise, so that the torque is transferred perfectly to the screw head via all four flanks. With a typical length of 25 mm for screwdriver bits and the standardised ¼ inch drive, the tiny screwdriving tool is a perfect replacement for worn or damaged bits in the toolbox and can be used with any standard bit holder or universal screwdriver with ¼ inch hexagon socket.

For a secure drive and fast processing of screws, it is important that the bit is firmly seated in the bit holder and does not jam in the screw or slip out of the bit holder. The lateral notches in the hexagon of the bit shank, also known as C-ring notches, serve this purpose. The profile shape of the drive must also be precisely manufactured. This is particularly important for screws with Phillips® drive, as if the bit does not fit or is not inserted deep enough into the cross of the screw, the bit can spin and thus turn the screw head drive round. This renders the screw unusable and, in the worst case, can only be removed with great effort.

Typical examples of Phillips® screws for bit size:

- Phillips®-bit PH1: Circuit board screws, electronic screws, furniture fittings, instrument screws, etc.

- Phillips®-bit PH2: Drywall screws, chipboard screws, machine screws, carriage bolts, etc.

- Phillips®-bit PH3: Construction screws, heavy-duty wood screws, deck screws, automotive screws, etc.

Typical examples for Phillips®- screws with a PH1 drive are used to fasten small electrical devices such as mobile phones, laptops or cameras, as well as circuit boards, spectacle frames and small toys. These screws are often used for more delicate work where a precise and secure fit is required. Phillips®- screws with a PH2 drive are often used for larger electrical appliances such as washing machines, dryers or fridges, for example, but also for building furniture, shelves or wooden structures. These screws are often used for medium to heavy-duty work where greater strength and stability are required. Phillips®-screws with a PH3 drive are intended for applications that require larger screws that have to withstand heavier loads. The areas of application are similar to those of size PH2, but the screws here are usually significantly longer and thicker, such as heavy-duty wood screws to connect thick wooden beams or heavy wooden structures or furniture assembly screws to ensure a secure and stable connection for particularly large and heavy pieces of furniture.

How do I recognise the right bit? Choosing the right bit is crucial if the bit or screw is not to be damaged. It is therefore advisable to take a look at the screw packaging, which in most cases contains specific information on the type of drive and specific bit size. Especially with Phillips® screws, where two types of drive are very common, the Phillips®-drive and the Pozidriv®-drive, which is a further development of the Phillips®-drive, choosing the wrong bit can quickly cause damage to the flanks of the bit or destroy the cross mount in the screw head. Recognising the right bit is very helpful here. Phillips®- screws are usually labelled with a circle and a simple cross. With Pozidriv®-screws the same symbol is supplemented by another, slightly thinner diagonally arranged cross. This symbolises the additional triangular profiles, each of which is located between two flanks. The situation is similar with the screws themselves. The drive of a Phillips ® screw looks like the plus symbol on the calculator. For a screw with Pozidriv®-drive, the view is more like a star with 8 points, which are alternately more and less pronounced.

- Additional Information

Additional Information

Product-ID BIT-PH Delivery Time Dispatch within 2-3 working days Material S2-Stahl Bit size No Take-up Shank ¼ inch drive (6.35mm) - Reviews