Pozidriv-Bits (single)

Our Pozidriv® bits made from high-quality S2 tool steel are available in the three sizes PZ1, PZ2 and PZ3 and are suitable for working with Phillips screws with Pozidriv® drive.

✓ Durable S2 steel

✓ For magnetic bit holders

✓ Standardised ¼ inch drive

✓ With restraint device

✓ Low wear and tear

The PZ bits for Pozidriv® screws are suitable for all bit holders with a hexagon socket in ¼ inches.

The item is in stock

Dispatch within 2-3 working days

- calculate the price

- from 10 Items €2.00/ pc. (Base Price €2.00/ pc.)

- from 50 Items €1.50/ pc. (Base Price €1.50/ pc.)

- from 100 Items €1.00/ pc. (Base Price €1.00/ pc.)

All prices include 19% VAT.

0,00 € / pc.

0,0000 kg / pc.

All prices include 19% VAT.

- Description

Pozidriv®-bits in all sizes

From 1 piece ✓ Attractive graduated prices ✓ Durable S2 steel ✓

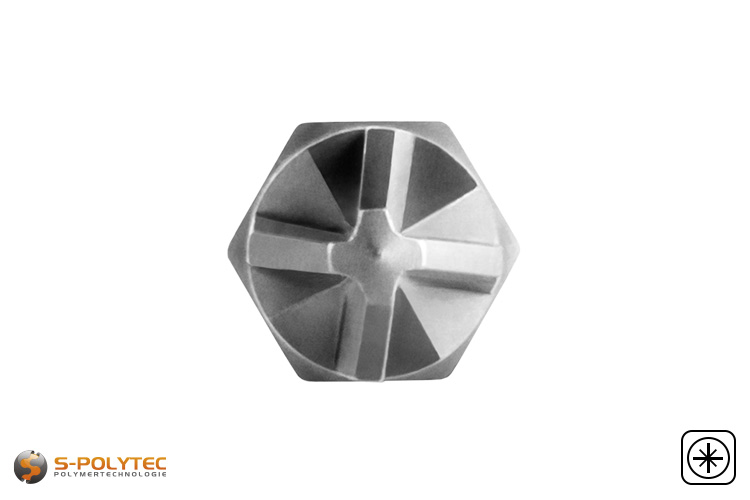

Our Pozidriv® bits are available in three variants of PZ1, PZ2 and PZ3, with the PZ2 size bit being one of the most used Phillips drives and therefore the most likely to require replacement. Thanks to the standardised bit size of ¼ inch (equivalent to 6.35 mm), our screwdriver bits can be used in all commercially available bit holders. Thanks to the typical hexagonal shape, it is also possible to use the bit without a special bit holder and insert it directly into the chuck of a drill. The overall length of the bit is 25mm, which is also common for a standard-sized bit.

To prevent the bit from slipping out of the bit holder when screwing, the hexagon socket is notched at the corners. Bit holders with a retaining device hook into this so-called C-ring notch and hold the bit securely in place. In addition, our Pozidriv® bits made of robust S2 quality steel are magnetic, so that a bit holder with integrated magnet can also be used, which not only has an effect on the hold of the screwdriver bit, but also makes work easier when inserting and screwing in screws made of magnetic metals such as stainless steel.

Bit broken? No problem - buy a new Pozidriv®-bit. This is actually possible with us, because we sell all our screwdriver bits individually. For larger quantities, however, you can benefit from attractive volume discounts with potential savings of up to 50%.

Scope of delivery:

- 1xPozidriv® bit in selected size

NOTE: To avoid damaging the drive of the Pozidriv® screw or turning it round, worn or damaged Pozidriv ®-bits should no longer be used and replaced with a new bit.

Features of our bit inserts with Pozidriv®-drive

Most screwdriver bits in bit assortment boxes are of rather mediocre quality, which is reflected in their low wear resistance. With our bits made from high-quality S2 tool steel, which is characterised by remarkably high stability and high-precision manufacturing, wear is reduced so that damage to screw drives caused by excessively worn flanks of the Pozidriv®-bits are to be feared less quickly. With a standard length of 25 mm, the Pozidriv®-bits are a perfect replacement for worn or defective bits and can be used with any standard bit holder or universal screwdriver with a ¼ inch hexagon socket thanks to the standardised ¼ inch drive.

A Pozidriv®-bit, in contrast to a Phillips bit, has 4 straight main flanks between which there are small triangular profiles. High-precision profile milling is extremely important to ensure that the bit fits perfectly into the screw drive to prevent it from slipping out when the screw is screwed in. High tightening torques are usually required for screws of this type in particular, which was the reason for the further development of the cross-recess drive. However, the high tightening torque can also very quickly result in damage to the screw head or the bit itself if the bit does not fit properly or is not inserted correctly into the drive of the screw. The small notches inside the ¼ inch hexagon socket are also important. These are also known as C-ring notches and reduce the risk of the bit falling out of the bit holder or getting stuck in the screw head. This is not only annoying, but also costs time and, depending on the specific application, a bit falling out can also pose a hazard, for example when working at a great height or on electrical machines and equipment.

Typical examples of Pozidriv® screws for bit size:

- Pozidriv®-bit PZ1: Model screws, electronic screws, fine adjustment screws, etc.

- Pozidriv®-bit PZ2: Wood screws, socket covers, furniture screws, dowel screws, etc.

- Pozidriv®-bit PZ3: Large wood screws, car body screws, steel girder screws, etc.

Pozidriv®-screws with a PZ1 drive are typically used for smaller and more precise applications where a secure and stable connection is required. These include, for example, small electrical components such as switches and sockets or fastenings for small cabinet and door fittings or screws for fine adjustment and fastening in musical instruments such as guitars, violins and other stringed instruments. Pozidriv®-screws with a PZ2 drive are the most common. In woodworking, PZ2 screws are often used for construction projects, decking, fencing and other wooden structures. Screws of this type are also used to fasten larger pieces of furniture such as wardrobes, beds and shelves. The format is also widely used in the automotive industry to ensure the secure fastening of interior panelling, dashboards and other components. Screws with a PZ3 drive are quite rare and are typically used for larger and more resilient applications where an extremely strong and very stable connection is needed. These include screw connections for large wooden structures such as carports, sheds, garden sheds or the fastening of large body parts, chassis and heavy add-on parts in commercial vehicle construction. PZ3 screws are even indispensable in shipbuilding and the aerospace industry. Here, the screws are primarily required for connections that have to withstand high loads and vibrations, where high strength and reliability are of great importance.

What is the difference between PZ bits and PH bits? Pozidriv® (PZ) and Phillips® (PH) are two different types of cross-slotted drives, each developed for specific applications and requirements. Also, the Pozidriv®-drive is a further development of the Phillips®-drive and allows higher tightening torques without slipping out of the screw drive. Put simply, Phillips®-bits are more suitable for general applications where controlled slippage may be desired so that the screw is not turned too tightly. Pozidriv®-bits, on the other hand, are used for applications that require higher torques and a more stable connection. The additional contact points reduce slippage and enable better force transmission. In most cases, the packaging of the screws already indicates which bit size and variant is required. This is often accompanied by a small symbol for labelling. The symbol for the Pozidriv®-drive has a cross-slot design reminiscent of a plus in a circle, but with the addition of four finer lines arranged diagonally between the main slots. A look at the screw head of a Pozidriv®-screw also reveals these additional diagonals very clearly. On the Phillips®-screw, only a circle with two intersecting lines can be recognised as a symbol. The diagonals are missing both on the symbol and in the drive of the Phillips design of the screw itself.

- Additional Information

Additional Information

Product-ID BIT-PZ Delivery Time Dispatch within 2-3 working days Material S2-Stahl Bit size No Take-up Shank ¼ inch drive (6.35mm) - Reviews