Aqua-Plus PP-R screw coupling female thread

The Aqua-Plus PP-R coupling with screwable female thread made of brass with integrated sealing ring allows a flexible connection of PP-R pipes with other pipe systems which can be released at any time if required.

✓ With internal thread (female)

✓ Screwable thread

✓ Temperature resistant up to +95°C

✓ Solid brass thread

✓ Sealing ring included

The white PP-R screw couplings (IG) are available in the sizes DN20x1/2 inch, DN25x3/4 inch, DN32x1 inch and DN40x1 1/4 inch.

The item is in stock

Dispatch within 2-3 working days

- calculate the price

- from 10 Items €4.40/ pc. (Base Price €4.40/ pc.)

- from 20 Items €4.28/ pc. (Base Price €4.28/ pc.)

- from 50 Items €4.17/ pc. (Base Price €4.17/ pc.)

All prices include 19% VAT.

0,00 € / pc.

0,0000 kg / pc.

All prices include 19% VAT.

- Description

Aqua-Plus PP-R screw coupling with female thread

Screwable brass thread ✓ With sealing ring ✓ Easy screwing ✓

The white Aqua-Plus PP-R couplings with screwable internal thread and integrated seal are available to match our white PP-R pipes in 20mm to 40mm diameter. The brass thread varies from 1/2" to 1 1/4", depending on the diameter of the PP-R pipe. The screw coupling thus combines a fixed welded connection of a PP-R pipe system with the flexible connection option of a screw connection, which can be released at any time by means of the coupling screw connection.The possible uses of the water- and pressure-tight pipe system range from drinking water supply and heating construction to food processing industries.

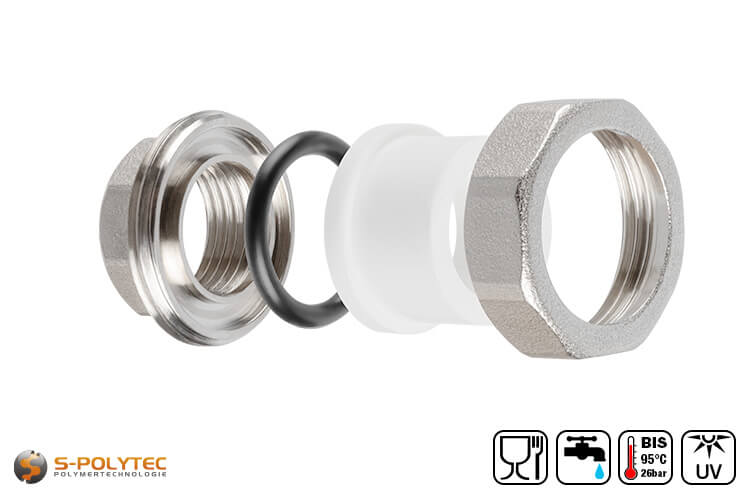

The screw coupling of the Aqua-Plus PP-R pipe system consists of four individual components, in which the female thread connection is firmly connected to the weldable pipe receptacle made of white polypropylene with a coupling screw connection, which is also made of a brass alloy. For perfect sealing of the screw coupling, there is a sealing ring between the threaded connection and the PP-R plastic.

Scope of delivery:

- 1 x Aqua-Plus PP-R screw coupling with female thread in white

Properties of the multi-part PP-R coupling with female thread

Our PP-R pipe couplings with screwable female thread made of brass are the perfect connection option to our screw couplings with male thread and are also very suitable for establishing a screw connection with a T-coupling with male thread in the same thread diameter. The PP-R pipe socket, which creates a permanent connection to a PP-R pipe by welding, is characterised by good sleep resistance, which is typical for polypropylene. The very good resistance to chemicals, such as alkalis or acids, are also positive properties of this plastic, which is why the PP-R pipe system is very well suited for delivery lines in the chemical and pharmaceutical industries. With a temperature resistance of -10°C, PP-R is frost-resistant. The upper limit of the continuous service temperature is +95°C. This means that the pipes and fittings can also be used for hot water supply in sanitary facilities, in heating construction or in geothermal energy.

The smooth-running threads made of solid brass, as well as the fitting made of white polypropylene, are characterised by a very good quality of workmanship. Like all components of the Aqua-Plus pipe system, the coupling is produced in Greece. The production within the EU ensures higher quality standards than cheap productions, which is proven by various DIN and EN standards for which the system may be used. Above all, the certifications by the DVGW, as well as the SKZ, are among the most noteworthy test centres that prove that the Auqa-Plus system can be used for pipelines for drinking water supply.

To ensure that the connection between the threaded insert and the weldable pipe receptacle is watertight up to an operating pressure of 26 bar, a sealing ring is inserted into the threaded insert, which seals tightly against the plastic after it has been screwed to the coupling fitting.

Size overview of the PP-R couplings with female thread

- PP-R coupling DN20x1/2" IT: For PP-R pipes with Ø outside 20mm - internal thread Ø 1/2"

- PP-R coupling DN25x3/4" IT: For PP-R pipes with Ø outside 25mm - internal thread Ø 3/4"

- PP-R coupling DN32x1" IT: For PP-R pipes with Ø outside 32mm - internal thread Ø 1"

- PP-R coupling DN40x1 1/4" IT: For PP-R pipes with Ø outside 40mm - internal thread Ø 1 1/4"

Processing of the screwable PP-R couplings with female thread

To make a connection with the PP-R screw coupling and a PP-R pipe of the same diameter, they must be welded together. A welding device for plastic pipes is required for this. Welding is done by inserting the pipe into the socket of the socket welder. The PP-R pipe holder of the screw coupling, on the other hand, is placed on the heating mandrel at the same time. After the heating time has elapsed, the two elements must be inserted into each other. This must be done without turning until the insertion depth is reached. An axial deviation of more than 3 degrees can have a negative effect on the tightness of the welded joint, which is why care should be taken when joining that the pipe is inserted straight into the socket. Finally, the welded joint should rest for a certain time to cool down.

WARNING: Before heating, the outer threaded fitting should be pushed onto the tube, because this is no longer possible after welding.

We offer the coupling fittings for pipes in various outer diameters from 20mm to 40mm. As the tube diameter increases, so do the heating and cooling times. The insertion depth also depends on the diameter, so that we have created a separate assembly data sheet for each tube diameter, which contains this information as well as valuable details on assembly. The data sheets can be viewed and printed in the tab of the same name.

After the welded connection has cooled down, the screwable coupling with internal thread can be loosened and tightened as desired. This allows flexible pipe connections that can be loosened at any time by unscrewing the coupling screw connection. Especially for connections of high-maintenance transport lines in industry and food production, the coupling fitting is an excellent choice and is more suitable for such purposes than our pipe couplings with fixed threaded connection.

Technical data of the screwable coupling for PP-R pipes

- Product type: Pipe coupling

- Material (angle): Polypropylene random copolymer

- Material (thread): Brass

- Edition: Internal threaed

- Thread diameter: 1/2"-1 1/4"

- Outer pipe diameter: 20,0mm-40,0mm

- Change of direction: None

- Temperature resistance: -10°C - +95°C

- Food approval: Yes

- Drinking water approval: Yes

- DVGW certified: Yes

- Corrosion resistance: Excellent

NOTE: To achieve a reliable seal of the screw connection, the use of hemp or Teflon tape is recommended for brass threads.

- Additional Information

Additional Information

Product-ID PPR-KUPPIG-DN00 Delivery Time Dispatch within 2-3 working days Size No Version Screw coupling Ø Thread varies Dimensions (W/H/D) varies Insertion depth varies Heating time varies Cooling time varies Plastic Polypropylene Material Polypropylene random copolymer UV resistance UV stabilized Color White - Reviews

- Attachments