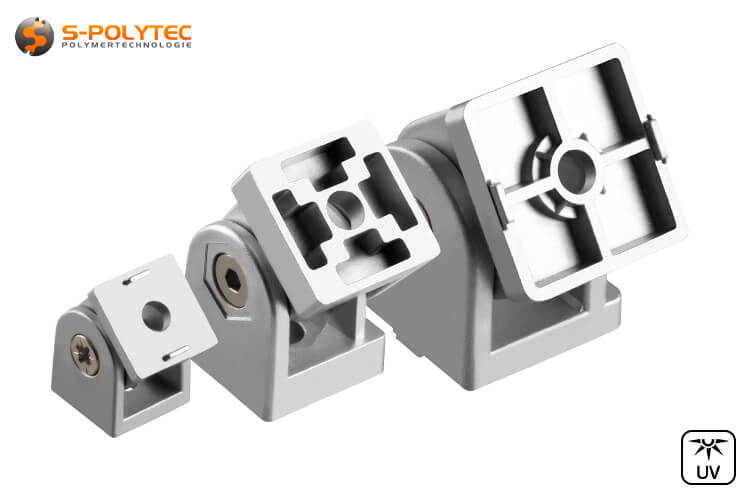

Profile connector with adjustable angle

The profile connectors with adjustable angle made of corrosion-resistant die-cast zinc are used for stable connections of construction profiles at any angle. They are easily mounted with cylinder head screws in the through-hole of the profile.

✓ Corrosion-resistant die-cast zinc

✓ Adjustable angle from -90° to +90°

✓ Precisely fitting profile end

✓ No need for a washer

✓ With anti-twist protection

✓ For indoor and outdoor use

The adjustable angle connectors are available in three sizes to match our construction profiles.

The item is in stock

Dispatch within 2-3 working days

- calculate the price

- from 10 Items €5.80/ pc. (Base Price €5.80/ pc.)

- from 20 Items €5.70/ pc. (Base Price €5.70/ pc.)

- from 50 Items €5.60/ pc. (Base Price €5.60/ pc.)

All prices include 19% VAT.

0,00 € / pc.

0,0000 kg / pc.

All prices include 19% VAT.

- Description

Profile connector for construction profiles with adjustable angle

Variable angle adjustment ✓ Perfect profile finish ✓ Angle from -90° to +90° ✓

Our profile connectors with adjustable angle are available in three different sizes for square construction profiles with 20mm, 30mm and 40mm width. They are used to securely connect two profile ends at any angle. The angle is infinitely adjustable by 180 degrees and ranges from -90 degrees to +90 degrees. The solid construction made of die-cast zinc not only ensures an extremely high level of stability, but also allows for outdoor use. This makes the angle connector ideal for all constructions where a connection deviates from the usual 90 or 45 degrees. For example, for a roof construction of a bicycle shelter with a slight slope for rainwater drainage.

The angle connectors are perfectly matched to our construction profiles in terms of size and shape, but they are also suitable for all standard I-type construction profiles with rounded corners and a through-hole. The 20mm profile connector should have an M6 thread, or a diameter such that an M6 thread can be cut. For the two larger versions, there should be a thread of Ø8mm.

NOTE: Depending on the profile design, a cylinder screw with an M6 or M8 thread is required to mount the adjustable profile connectors to the construction profiles. For most construction profiles, the through-hole must also be threaded.

Properties of our variable angle profile connectors

Angle connectors are the best way to connect two construction profiles at any angle and are usually attached to the cut edge of the profile with a threaded screw that is screwed into the centrally located through-hole of the profile. To prevent the profiles from twisting, the angle connectors have grooved webs that fit perfectly into the grooves of the construction profile. The dimensions in terms of width and depth correspond to the common sizes for aluminium system profiles and are available in 20x20mm, 30x30mm, and 40x40mm. The height varies depending on the angle. We have listed the minimum and maximum heights below in the specific data. The angle connectors have slightly rounded corners, the corner radius of which matches our profiles and thus fits perfectly with the cross-section of the profile. They can also be combined with all other i-type construction profiles with rounded external corners. Even with the angular profiles of type B, a stable, resilient connection is possible, although the outer corners of the profiles protrude minimally due to the angular profile design.

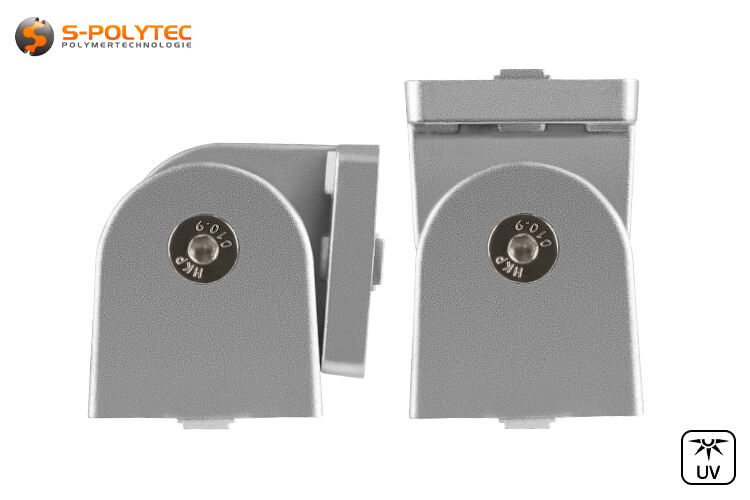

The angle connectors consist of two individual components that can be moved in relation to each other and are made of solid die-cast zinc. This is an alloy that is characterised by good mechanical strength and resistance to deformation. Die-cast zinc is also rust-free and can therefore be used outdoors without moisture or weather conditions affecting the lifespan of the construction. The low weight and attractive silver surface are further positive aspects of the zinc die-cast parts that are worth mentioning. The screws that connect the two brackets are made of high-strength carbon steel, whose nickel-plated surface is also characterised by good corrosion resistance.

NOTITIE: Very few construction profiles, including ours, are provided with a thread in the clearance hole, so that this still has to be cut in to screw in the cylinder screw. However, this is very easy to do with a simple M6 or M8 internal thread cutter, because aluminium is very easy to work with, so even thread cutting is not a challenge. The depth of the thread depends on the length of the screws, which should be screwed at least 30mm to 100mm into the profile, depending on the overall length and load of the frame construction.

Specific data of the profile connectors with adjustable angle

- Profile connector 20x20mm: Dimensions (WxDxH): approx. 20mm x 20mm x 30mm/24mm (0°/90°), Ø hole: 6.25mm, weight: 38g

- Profile connector 30x30mm: Dimensions (WxDxH): approx. 30mm x 30mm x 49mm/39mm (0°/90°), Ø hole: 7.75mm, weight: 120g

- Profile connector 40x40mm: Dimensions (WxDxH): approx. 40mm x 40mm x 59mm/47mm (0°/90°), Ø hole: 8.50mm, weight: 253g

Installation and use of variable profile connectors

Two cylinder head screws are required to connect two construction profiles with adjustable angle connectors, which should have a thread diameter of 6mm or 8mm. If it has not already been done, the clearance hole should be provided with a thread of sufficient depth to accommodate the length of the threaded screw, so that it can be screwed all the way into the clearance hole to achieve a secure, load-bearing connection. The length of the screw depends on the load that will later be applied to the construction and should be chosen to be slightly longer rather than too short.

Depending on the version, a Pozidriv® 2 cross-head screwdriver is required for the 20mm profile connector, or a 4mm Inbus® key for the 30mm or 40mm version, to loosen the side screw for the angle adjustment and to tighten it after installation. In addition, a tool is required for screwing in the cylinder head screw. For our 6mm cap screws, this would be a 5mm Allen® key. The 8mm cap screws with a hexagon socket drive, on the other hand, are screwed in with a 6mm key. The screw is inserted through the mounting hole of the profile connector and then screwed into the clearance hole of the profile. Small grooved webs on the mounting surface of the connector prevent the screwed-on profile from twisting under mechanical load after installation. The second construction profile is screwed on in the same way. Finally, the desired angle can be set and fixed with the side screw.

NOTE: The profile connectors are precisely matched to square construction profiles in terms of width. When assembling, it is important that the profiles are cut exactly at right angles, otherwise the angle will not close precisely with the profile. The screw head of the cylinder screw will also not be flush, which can have a negative effect on the strength of the screw connection. For this reason, we recommend using a chop saw with a fine-toothed saw blade for light metal when cutting the construction profiles to size, as well as deburring the cut edge after sawing.

Alternatively, it can be mounted inside the profile groove. However, this is only possible at right angles to the profile, as two groove webs are attached to the underside. These prevent the profile connector from twisting. In this case, it can be attached using a groove stone and a cylinder screw or a hammer screw in combination with a flange nut. The advantage of this mounting variant is that the profiles attached at an angle can be flexibly moved along the groove if necessary.

The variable angle adjustment represents a completely new level of flexibility when connecting construction profiles. For example, it is easily possible to construct a shelter for bicycles, rubbish bins or garden tools with a slight roof pitch so that rainwater can run off. The same applies to a small front door canopy to provide protection from the rain at least in the entrance area of the front door. Small greenhouses with frame structures made of construction profiles and glazing made of shatterproof polycarbonate can be built just as quickly and sturdily as a substructure for a balcony power plant, with a perfect angle of inclination for incoming sunlight, in order to get the most out of the solar system.

Examples of applications for flexible angle connectors

- The profile connectors with adjustable angle are ideal for greenhouse roof structures

- The variable angle makes the connectors perfect for the substructures of photovoltaic systems

- The adjustable angle is used to achieve the ideal roof pitch for shelters and canopies

- With angle connectors, a frame construction can be created as a triangle, polygon or trapezoid

- The angle connectors can also be used for wall-mounting swing doors, gates or folding tables

Technical data of profile connectors with adjustable angle

- Material (connector): Zinc die casting

- Material (screw): Carbon steel (nickel plated)

- Colour: Silver

- Angle: -90° up to +90°

- Height at 0°: 30mm up to 56mm

- Height at 90°: 24mm up to 47mm

- Ø Hole drilling: 6.25mm up to 8.50mm

- Weight: 38g - 253g

- UV-resistance: Excellent

- Weather resistance: Excellent

- Corrosion resistance: Sufficient

- Additional Information

Additional Information

Product-ID PRV-0000-F Delivery Time Dispatch within 2-3 working days Property Profile connector with adjustable angle Material Zinc die-cast with nickel-plated carbon steel screws Color Silver - Reviews

You may also be interested in the following product(s)

Aluminium construction profile 20x20, groove 6 silver (anodised)

Aluminium construction profile 30x30, groove 8 silver (anodised)

Aluminium construction profile 40x40, groove 8, silver (anodised)

Corner connector for construction profiles (internal)

Slot nuts for construction profiles

Profile connectors for construction profiles