Trespa® Meteon® FR UNI COLOURS 2x1meter

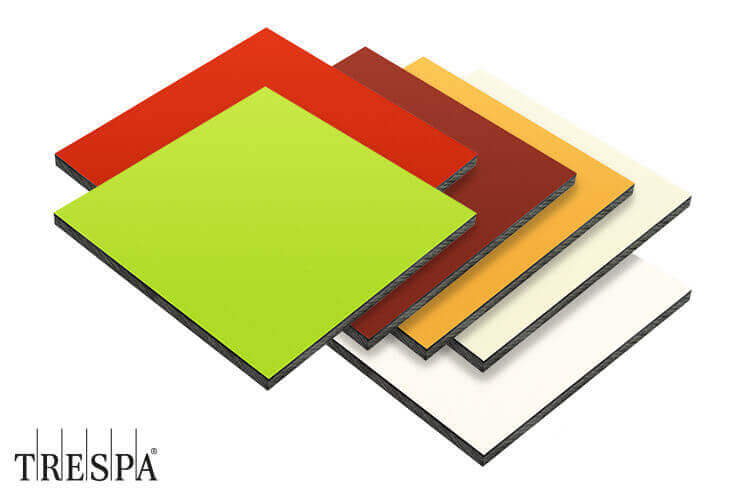

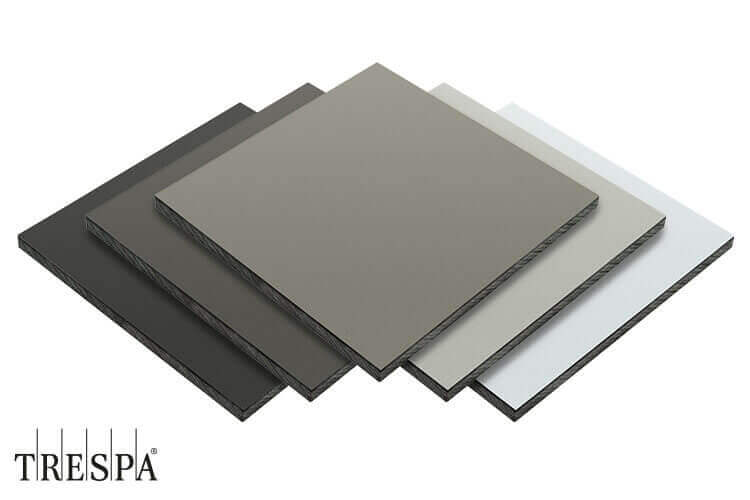

The HPL panels Trespa® Meteon® FR UNI COLOURS in the 2x1 metre format are available in many colours with a single-colour surface decor on both sides in a satin finish and are characterised by enormous durability and very high weather resistance.

✓ Many colours available

✓ Surface decor on both sides

✓ UV- and weather resistant

✓ Flame retardant according to EN 438-7

✓ Facade approval according to DIBt

The single-colour facade panels from Trespa® are available on request in many other colours and formats, as well as precisely cut to size.

The item is in stock

Dispatch within 2-3 working days

- Standard panels

- at pieces 0,00 € (Base Price 0,00 € / m2)

- at pieces 0,00 € (Base Price 0,00 € / m2)

- at pieces 0,00 € (Base Price 0,00 € / m2)

All prices include 19% VAT.

0,00 € / pc.

0,0000kg / pc.

All prices include 19% VAT.

- Description

Trespa® Meteon® FR UNI COLOURS - THE facade panel made of HPL

Many colours in stock ✓ Flame-retardant design ✓ Incl. facade approval ✓

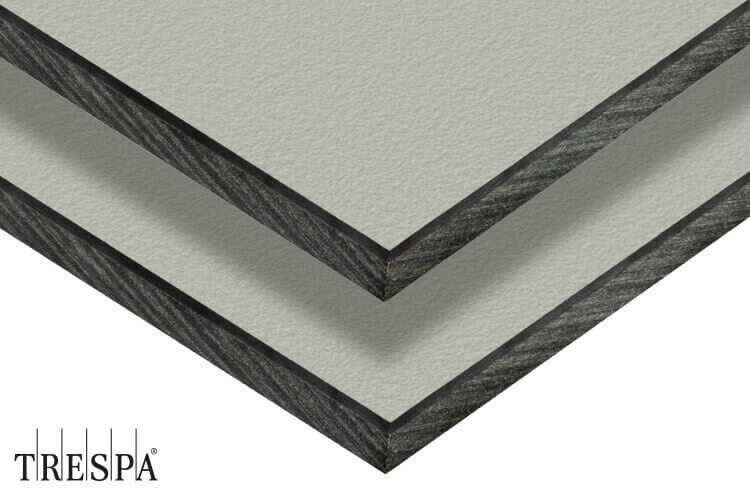

The Trespa® Meteon® FR UNI COLOURS panels are high-quality high-pressure laminates with a thickness of 8 mm, which are suitable as decorative exterior wall cladding for ventilated facade systems. For these purposes, the solid panels meet the strict requirements for fire behaviour of various European and international standards and are considered flame retardant. The surfaces of the UNI COLOURS series are available in many different colours. In our delivery programme, we deliberately rely on a decor on both sides, in which the front and back of the HPL panels have the same colour in a silk matt satin finish, so that the rigid panels can also be used for partition walls and interior furnishings.

We offer the high-quality Trespa® Meteon® facade panels with decor on both sides in various shades of white and grey, as well as in trendy colours in our standard format with 2000mm length and 1000mm width. Other colours, as well as matt, glossy or structured surfaces, are available on request. In addition, depending on the design, HPL panels of the Trespa® brand are also available as individual cuts or in standard formats of 3050 x 1530mm, 3650 x 1860mm or 4270 x 2130mm. Simply send us a short email with the dimensions you require, specifying the colour, decors and surface finish. Our friendly team will promptly send you a customised quote, including shipping costs, based on your specifications.

Our standard delivery programme for Trespa® Meteon® FR UNI COLOURS

All the colour versions of the panels from our standard delivery programme listed below have the same colour on both surfaces with a satin matt finish. The size of our standard format is 2000mmx1000mm.

- A03.0.0 White between RAL9001 (Creme) and RAL9010 (Pure white)

- A05.0.0 Pure White similar to RAL9003 (Signal white)

- A21.1.0 Winter Grey between RAL9018 (Papyrus white) and RAL7035 (Light grey)

- A03.4.0 Silver Grey similar to RAL7038 (Agate grey)

- A21.5.1 Mid Grey similar to RAL7037 (Dusty Grey)

- A21.7.0 Steel Grey similar to RAL7011 (Iron grey)

- A25.8.1 Anthracite Grey similar to RAL7016 (Anthracite grey)

- A12.3.7 Carmine Red similar to RAL3002 (Carmine red)

- A12.6.3 Wine Red between RAL3004 (Purple red) und RAL3005 (Wine red)

- A37.0.8 Lime Green a little more intense, brighter than RAL6018 (Yellow Green)

- A04.1.7 Gold Yellow similar to RAL1007 (Daffodil Yellow)

Properties of Trespa® Meteon® FR facade panels

The Trespa® brand stands for products that are characterised by outstanding and consistently high quality. It is not without reason that Trespa International is one of the leading manufacturers of decorative panels for facade cladding. This includes the Trespa® Meteon® FR HPL panels, which are designed to last for at least 50 years when properly installed. This is a high-performance material that is suitable for extremely high-quality and durable facade and balcony cladding, as well as countless possible uses both indoors and outdoors.

Among the most important features of the panels are the fire behaviour classifications, which are classified as flame-retardant by various standards, as well as the excellent weather resistance. These properties are of utmost importance if the single-colour decorative panels are to be used outdoors as cladding for vertical facade systems or for ceiling soffits. After all, it is hardly worth investing in materials and labour to clad an exterior wall if this is not going to last long due to inadequate UV and weathering resistance. With Trespa® Meteon® FR this is not to be feared. Even prolonged, strong sunlight does not cause any perceptible changes to the surface, which is proven by elaborate test procedures for grey scale evaluation for colour or in contrast. In combination with suitable installation materials and professional installation, Trespa® Meteon® FR facade panels have a general type approval for ventilated facade systems, which is also referred to as facade approval in common parlance.

HPL is also characterised by excellent physical properties. Thanks to their very good resistance to moisture, high-pressure laminates are considered water-resistant panels. This is due, among other things, to a very low water absorption of maximum 0.5%. Also in terms of dimensional stability at elevated temperatures, which can be quickly reached in direct sunlight, the facade panels from Trespa® Meteon® are absolutely convincing. With a very low expansion of less than 0.25%, both in the longitudinal and transverse direction, the panel dimensions change only extremely slightly. With our standard 2x1 metre format, this means a maximum expansion of 5.0 mm in relation to the panel length, or 2.5 mm in relation to the width of the panel. However, even with such small expansions, a constraint-free installation is essential for HPL cladding.

Approvals and standards for HPL sheets

- Flame retardant according to DIN EN 438-7 B-s1, d0 (corresponds to DIN 4102-1 B1)

- Balcony approval according to ETB guideline "Components that protect against falling"

- Facade approval in accordance with general type approval as a rear-ventilated facade system

- FSCTM-certified or PEFCTM-certified variants are available on request

On request, the high-quality cladding panels are also available in many other colours.

Application examples for Trespa® Meteon®

Facade cladding with Trespa® Meteon® FR Due to the closed, almost pore-free surface, dirt adhesion is largely prevented. The chemical resistance, which also proves itself against strong cleaning agents, also contributes to the fact that facade claddings with HPL panels have a long-lasting beautiful appearance. The effort required for maintenance and cleaning is considerably less than that required for dirt-prone thermal insulation composite systems with surface plaster. Even graffiti can usually be removed very easily from the surface with suitable cleaning agents. It is not for nothing that vertical wall cladding in the outdoor area with Trespa® Meteon® is so popular.

The installation is based on different criteria. The installation material also varies, depending on the substructure. While approved facade screws and an EPDM joint sealing tape must be used for substructures made of wood, riveting with facade rivets with a head diameter of 16 mm is required for substructures with aluminium profiles. The type approval of the panels as a rear-ventilated facade system, which we receive from the panel manufacturer and have made available for download in the data sheets tab, contains very detailed information on how the installation as facade cladding is to be carried out, how the fastenings are to be selected and which installation distances are to be observed. In most cases, the installation is carried out with an open joint. This means that the panels are installed with a visible gap next to or above each other. This must be at least 10 mm due to the thermal expansion of HPL laminates.

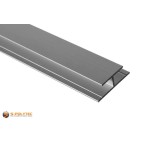

As an alternative to vertical facade cladding with open joints, the gaps between adjacent panels can also be covered with our joint profiles. Please note that the distance between the two panels increases by the material thickness of the aluminium profile. In the case of our H profiles with a clamping range of 8mm and a profile thickness of 1mm, this means that the mounting distance between two panels must be 11mm. However, our profiles still have sufficient edge overlap on the visible side, so that they can be perfectly used for such purposes. In addition to the visual aspects, this also prevents insects, moisture from rain or dirt from getting behind the facade panels. It also closes any cold bridges, which has a positive effect on the efficiency of additional, optional thermal insulation.

Balcony cladding with Trespa® Meteon® FR HPL panels are also very suitable as balcony edging and guarantee the necessary protection against falling while at the same time providing effective privacy. In order for the Trespa® panels to be used for this purpose, they have been tested in accordance with the ETB guideline "Components that protect against falling". However, the installation depends on the type of substructure to which the panels are attached. Due to the large number of different systems and balcony construction methods, the specifications of the panel manufacturer, the installation instructions of the balcony builder and legal regulations must be observed before installing the balcony cladding.

However, the balcony railing is usually made of metal, so we also offer suitable fastening solutions to match. These include our large-head rivets for HPL, or stainless steel balcony screws (optionally with threaded sleeve or cap nut) in various lengths. These are each available as unpainted or, matching the decor, painted versions.

HPL panels in interior design Thanks to the many different colour versions, the sturdy panels match any furnishing style. From simple room dividers in doctors' surgeries and open-plan offices in neutral white or light grey, to targeted colour accents, e.g. as a kitchen splashback in Lime Green, Carmine Red or Golden Yellow, to shower splash backs in trendy dark grey tones that form a great contrast to light wall tiles. Trespa® Meteon® FR UNI COLOURS are a very good choice for countless interior design purposes. Thanks to the decor on both sides, the tiles can even be used free-standing or in furniture construction.

- As a ventilated facade system, HPL is a durable alternative to external thermal insulation composite systems

- HPL is very well suited as privacy and fall protection on balconies and roof terraces

- The single-coloured panels are excellent for creating stable room dividers and partitions

- HPL is an ideal substitute for tiled backsplash in the kitchen and is very easy to clean

- As a waterproof panel, HPL can also be used as a shower back panel or wall cladding in the bathroom

- The flexurally rigid panels are also suitable as small shelves, cupboard and sliding doors

- and many more

Processing of HPL facade panels

HPL is a very hard material, which places certain demands on the tools, especially in machining processes, because with simple drills or saw blades, which are suitable for normal wood or plastic, you are not well advised with high-pressure laminate, because these would wear out too quickly.

sawing HPL panels For facade cladding, straight cuts are usually made, which are easiest to implement with a circular saw. The best results can be achieved with a saw blade with alternating teeth or trapezoidal flat teeth and a high saw blade projection of 10%. The panel should be placed with the visible side facing the saw. This means that with a fixed table saw or panel saw, the visible side is facing upwards. With hand-held circular saws or jigsaws, the visible side should face downwards. For inside corners and cut-outs, a circular saw is usually not well suited, so the jigsaw is better to use here. We advise using special saw blades made of carbide for precision cuts for HPL, as this achieves a much cleaner cut pattern. The so-called Precision Cut saw blades are available from almost all leading manufacturers.

Drilling HPL panels For assembly with screws or rivets, holes must be drilled. These can be done with an HSS drill, but a special HPL drill made of solid carbide produces more precise holes. When drilling, HPL should always be placed on a firm surface so that the drill does not poke through into the empty space when it comes out. Otherwise, unsightly edge chipping of the decorative surface cannot be ruled out. For facade screws, the panel is drilled with an 8 mm drill bit. The supporting wooden substructure is not drilled. For aluminium substructures, the profiles are all drilled with 5.1mm. In the case of the panel, however, only the fixed point is drilled in this diameter, which matches the rivet. All other fastenings serve as sliding points for thermal expansion and must be drilled with a 10mm diameter drill.

Cleaning HPL panels The HPL panels from Trespa® are characterised by a closed, almost pore-free surface on which dirt accumulation is largely avoided. Nevertheless, dust and soot can accumulate on the surface over time due to environmental influences. External influences or vandalism can also cause unwanted soiling on the surface, but in most cases this can be removed from the surface with suitable cleaners. HPL is extremely resistant to chemicals and can even be cleaned with cleaning agents containing acids or solvents. In this way, even stubborn dirt such as sticker residues or graffiti can be removed. Soft cloths, sponges or soft nylon brushes are particularly suitable for cleaning. Scouring sponges or brushes with stiff bristles should be avoided, however, as these can damage the surface. The same applies to cleaning agents that contain abrasives or polishing particles. These should also be avoided.

NOTE: The manufacturer Trespa International presents on its website www.trespa.info extensive information on processing, installation, cleaning and many other topics relating to Trespa® Meteon® facade panels is available for download.

Materialeigenschaften von Trespa® Meteon® FR

- Colour: On both sides, according to selection

- Finish: On both sides satin (satin finish)

- Strength: 8mm

- Strength tolerance: +/- 0,50mm according to EN 438-2.5

- Physical density 1,35 g/cm3

- Temperature resistance: from -30°C up to +80°C

- Bending module min. 9.000 MPa according to EN ISO 178

- Bending strength min. 120 MPa according to EN ISO 178

- Length expansion max. 0,25 % according to EN 438-2.17

- Width expansion max. 0,25 % according to EN 438-2.17

- Thermal conductivity 0,3 W/mK according to EN 12524

- Water absorption 0,5% according to ASTM D2842-06

- Mass increase: max. 3% according to EN 438-2.15

- Fire behaviour: Flame retardant

- UV-resistance: Excellent

- Weather resistance: Excellent

- Chemical resistance: Excellent

NOTE: Detailed information on specific material properties is provided by the manufacturer on its website www.trespa.info.

Trespa® is a registered trademark of Trespa International.

- Additional Information

Additional Information

Product-ID TRS8FR-UCSA Thickness 8 Standart Length 2000 Standard width 1000 Delivery Time Dispatch within 2-3 working days Plastic High pressure laminate Material High-pressure laminate (HPL) Fire behaviour Flame retardant Color No Decor No Color designation varies Finish Satin UV resistance UV resistant - Reviews