Trespa® Meteon® FR WOOD DECORS 2x1meter

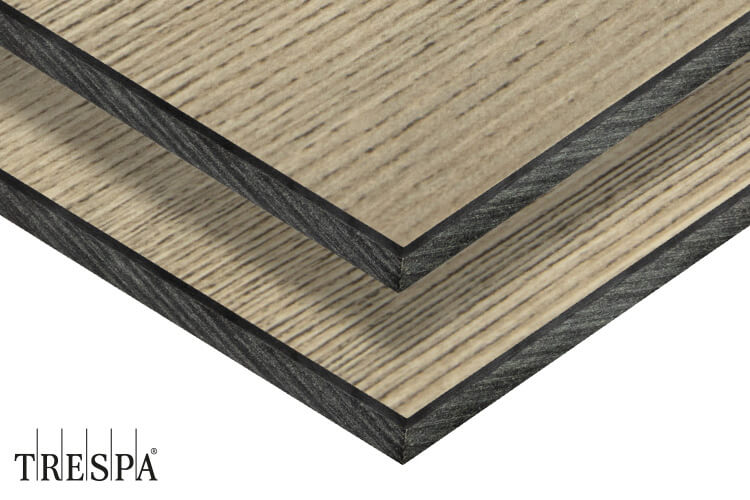

The HPL panels Trespa® Meteon® FR WOOD DECORS in the 2x1 metre format are available in various wood decors with a decorative surface on both sides with a matt finish and are characterised by an enormous service life as well as high weather resistance.

✓ Various wood decors available

✓ Decorative surface on both sides

✓ high UV and weather resistance

✓ Fire behaviour B-s1, d0 according to EN 13501-1

The decorative facade panels from Trespa® are available on request in many other wood decors and formats, as well as precisely cut to size.

The item is in stock

Dispatch within 2-3 working days

- Standard panels

- at pieces 0,00 € (Base Price 0,00 € / m2)

- at pieces 0,00 € (Base Price 0,00 € / m2)

- at pieces 0,00 € (Base Price 0,00 € / m2)

All prices include 19% VAT.

0,00 € / pc.

0,0000kg / pc.

All prices include 19% VAT.

- Description

Trespa® Meteon® FR WOOD DECORS - THE facade panel in wood look

Various wood decors in stock ✓ Fire behaviour B-s1, d0 according to EN 13501-1 ✓

The Trespa® Meteon® FR WOOD DECORS panels are HPL panels with realistic wood-look surface decors. These are available from us with a thickness of 8mm in various wood colours with a surface decor on both sides in our standard format of 2x1 metre. In contrast to the single-colour panels in the UNI COLOURS collection, the wood-look surfaces are completely matt, which comes closest to the effect of a real wooden panel. The Trespa® Meteon® FR panels are enormously resistant to bending and can be used for ventilated facade systems.

The decorative facade panels with a matt finish on both sides are available from us in four popular wood decors. On request, we can also supply the Trespa® Meteon® FR WOOD DECORS panels in many other wood-look finishes, for example Wenge, Dark Mahogany, Nordic Black or light Core Ash. In addition to our own standard format, we also offer the manufacturer's standard formats of 3050x1530mm, 3650x1860mm or 4270x2130mm, as well as cut-to-size panels in your desired size. However, due to size and weight-dependent shipping costs, these are only available from us on request. Simply send us an e-mail and you will receive an individual offer in a timely manner.

Our standard delivery programme for Trespa® Meteon® FR WOOD DECORS

All of the wood-look panel designs listed below, which we have selected to include in our standard delivery programme, feature the same wood decor with a matt surface finish on both surfaces. The size of the panels in our standard format is 2000mm x 1000mm and thus deviates from the standard formats of the manufacturer. The grain of the wood structure runs along the long side of the panels.

- NW02 Elegant Oak Wood grain and colour resembles light oak

- NW08 Italian Walnut Wood grain and colour resembles Italian walnut

- NW24 Greyed Ceder Wood grain and colour resembles grey stained cedar wood

- NW28 Halmstad

Properties of the Trespa® Meteon® FR panels in wood look

The facade panels of the trade brand Trespa® are used worldwide for small and large construction projects to clad exterior facades. This is mainly due to the very high quality of the panels. It is not without reason that the panels have a service life of approximately 50 years when professionally installed. High-pressure laminate, from which the panels are made, is an enormously high-performance material that is characterised by enormous rigidity as well as very good chemical resistance. Environmental influences such as soot particles, acid rain, chemical cleaning agents, even concentrated acidic cleaners, cannot harm the high-quality Trespa® Meteon® FR panels. This makes these panels the ideal choice for high-quality and durable cladding of facades, ceilings and balconies in outdoor areas.

One of the essential properties that distinguishes Trespa® Meteon® FR panels in wood look from simple HPL panels is their suitability for use as a ventilated facade system. The fire behaviour is important here. In the case of Trespa® Meteon® FR, this is recognisable by the abbreviation FR (flame retardant) and is classified as B-s1, d0 according to EN 13501-1. As panels for outdoor use, Trespa® panels naturally also have high UV and weather resistance and defy all weather conditions, from strong sunlight to persistent rain. There is no need to fear weathering or fading of the attractive wood decors.

Application examples for Trespa® Meteon® FR WOOD DECORS

Cladding facades with Trespa® Meteon® FR The wood decors of the Trespa® Meteon® FR WOOD DECORS collection impress with a very detailed, realistic surface that is difficult to distinguish visually from real wood. This allows wall cladding of exterior facades in a trendy wood look, which, in contrast to real wood, is considerably more durable and requires less maintenance. Unlike wood, the decorative panels do not rot or decay and are also much easier to clean due to their hard, closed surface. This means that the costs and time required for building maintenance can be reduced to a minimum.

If HPL panels are used for the exterior cladding of facades, a basic distinction must be made between two different fastening systems. On the one hand, screw fastening with facade screws on a substructure of wooden support battens. On the other hand, installation by riveting with facade rivets on supporting profiles made of aluminium. Regardless of the type of fastening, the installation must be carried out in accordance with a corresponding type approval, which clearly defines what the material properties of the substructure must be and which fasteners are permissible. In most cases, facade cladding is installed with an open joint. In this design, adjoining panels are mounted at a certain distance from each other. This applies equally to panels that are arranged horizontally as well as vertically to each other and serves as expansion space.

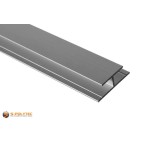

Another possibility is to close the joints with joint profiles, for example our aluminium H-profiles with a clamping range of 8mm. However, this must be considered before fixing the panels, because the distance between the individual panels must be increased by the thickness of the profile to ensure the necessary expansion space. In addition to visual reasons, joints closed by joint profiles can have the advantage that no moisture can get behind the cladding due to rain and thus possibly soak through existing thermal insulation boards. Furthermore, wind noise caused by open joints can be avoided.

TIP: By changing the direction of the wood grain from one panel to the next, both next to each other and on top of each other, a particularly striking and yet homogeneous appearance of the facade cladding can be achieved. This effect can be further enhanced by combining different decors in different wood colours and grains.

Trespa® Meteon® FR as balcony privacy screen The exterior panels from Trespa® are tested in accordance with the ETB guideline "Components that protect against falls" and are therefore also suitable for use as balcony surrounds. In most cases, however, the attractive decorative panels are not used as balcony privacy screens for this reason alone, but because they are appealing. However, visual demands do not exempt you from regulations, standards and guidelines, so there are a few points to consider when installing balcony cladding. As with facade cladding, the balcony railing, as the supporting structure to which the panels are attached, must also meet the requirements. In addition, suitable mounting material must be used. With our balcony screws, which we offer either as a version with self-locking cap nut or as a screw with threaded sleeve, we offer suitable fastening solutions for balcony surrounds.

For apartment buildings or terraced houses equipped with balconies, the combination of Trespa® Meteon® WOOD DECORS in various finishes can achieve a similarly modern, appealing effect as is possible with the facade claddings already mentioned.

Processing HPL facade panels

High-pressure laminate, to which the Trespa® Meteon® panels belong, is characterised by good mechanical properties. The panels are resistant to bending and enormously robust. Absolute advantages for facade cladding and balcony surrounds. However, this is also a slight disadvantage when referring to the processing of the panels alone, because the very hard surfaces place higher demands on saw blades, milling cutters or drills than simple panels made of plastic or wood-based materials.

Sawing HPL sheets Cutting hard HPL panels is possible with any simple hand-held circular saw or jigsaw. However, a fixed table saw with guide rail leads to a more precise, straight cut pattern, which is the most common type of cut, especially for facade panels. The essential difference for clean cut edges is the choice of a suitable saw blade. For circular saws, a saw blade with alternating teeth or trapezoidal flat teeth is the best choice. A high saw blade projection of 10%, in relation to the diameter of the saw blade, reduces the risk of tearing on the decorative surface and contributes to a clean cut. A circular saw is unsuitable for tight radii, small corners and cut-outs. A jigsaw is needed here. A precision saw blade made of hard metal, as offered by almost all well-known manufacturers, is most likely to work its way through the hard material. Conventional saw blades would anneal or dull too quickly. Also, the expected cutting pattern with a simple wood saw blade is too coarse and not suitable for boards with high visual demands. At best, sawing should be done in such a way that the saw is not placed on the visible side but on the opposite side.

Drilling HPL panels HPL panels are made of high-pressure laminate. This is a very hard material with an equally hard surface. Standard HSS drills can be used for drilling, but the service life of the drill is significantly reduced when drilling HPL. In this case, it is better to use a facade panel drill made of solid carbide. A special drill head geometry and a centring point ensure that the holes can be drilled with the highest precision and without slipping. A precise position of the fastening holes is very important, especially when installing with facade screws or facade rivets. The diameter of the panel hole depends on the mounting material. For facade rivets, one hole is drilled as a fixed point with a diameter of 5.1 mm. The remaining fastening points of the panel, on the other hand, must be drilled with a 10 mm drill bit so that the panel can be riveted without constraint. Please note that when assembling with rivets, the aluminium profiles as the supporting structure must always be drilled with a drill with a nominal diameter of 5.1mm. An HSS drill is well suited for the profiles. In the case of facade screws for mounting the panels on a substructure of wooden support battens, use a drill with 8mm. In this case, however, the substructure is not pre-drilled.

TIP: To prevent the decorative surface from splintering at the edge of the drill hole when the drill comes out, an HPL panel should always rest on a firm surface when drilling.

Cleaning HPL sheets The HPL panels from Trespa® Meteon® are hardly susceptible to dirt. This is due to the closed, almost pore-free surface of the outer panels, to which dirt adhesion is largely avoided. Depending on the area of application, however, soiling due to dust and soot cannot be completely prevented. However, these can be easily removed from the surface with clean water and a soft cloth or sponge. Due to the chemical resistance, the surfaces are not attacked even by solvent-based or acidic cleaners, so that even the most stubborn dirt such as graffiti can be removed with little effort. Scouring sponges, scouring milk or cleaners with an abrasive or polishing effect should be avoided, as these can leave fine abrasive marks that visually impair the decorative surfaces.

NOTE: On the website www.trespa.info the manufacturer Trespa® has provided a large number of instructions and data sheets for the care, cleaning, processing and installation of Trespa® Meteon® FR facade panels for a wide range of applications, which can be viewed and downloaded there.

Material properties of Trespa® Meteon® FR

- Colour: on both sides, wood decor according to selection

- Finish: matt on both sides

- Strength: 8mm

- Strength tolerance: +/- 0,50mm according to EN 438-2.5

- Physical density: 1,35 g/cm3

- Bending module: min. 9.000 MPa according to EN ISO 178

- Flexural strength: min. 120 MPa according to EN ISO 178

- Linear expansion: max. 0,25 % according to EN 438-2.17

- Latitudinal extent: max. 0,25 % according to EN 438-2.17

- Thermal conductivity: 0,3 W/mK according to EN 12524

- Water absorption: 0,5 % according to ASTM D2842-06

- Mass increase: max. 3 % according to EN 438-2.15

- Fire behaviour: EN 13501-1 as B-s1, d0

NOTE: The material properties listed have been taken from the manufacturer's data sheet and are only an excerpt from the material data sheet of the decor panels. These, as well as many other detailed information on physical, thermal and mechanical properties, are available on the manufacturer's website www.trespa.info which is made available for download as a PDF file.

- Additional Information

Additional Information

Product-ID TRS8FR-WDSA Thickness 8 Standart Length 2000 Standard width 1000 Delivery Time Dispatch within 2-3 working days Plastic High pressure laminate Material High pressure laminate (HPL) Fire behaviour Flame retardant Color No Decor No Color designation varies Finish Matt UV resistance UV resistant - Reviews