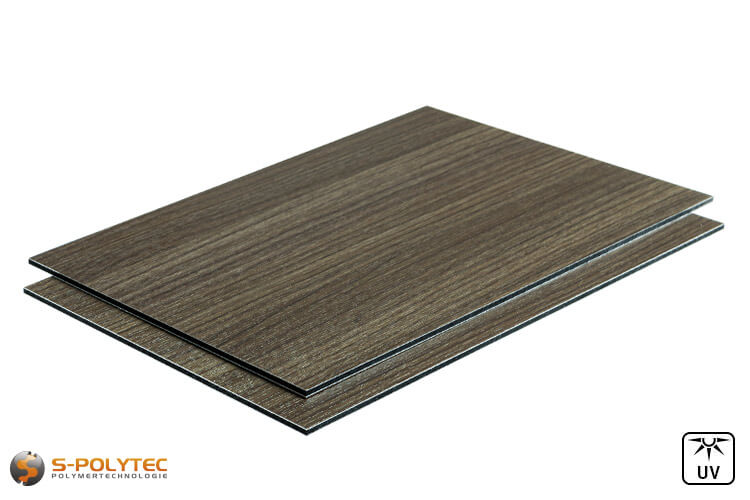

Aluminum composite panels wood decor ash 3mm

Weatherproof aluminium composite panel in wood look dark stained ash in 3mm thickness made to measure with tangible surface grain, conveniently cut to size and available online at best prices.

✓ Scratch-resistant surface structure

✓ UV- & weather-resistant

✓ For indoor and outdoor use

✓ Suitable for damp locations

✓ Protective film on both sides

The grained aluminium composite panels in wood decor are available in sizes up to 1500mmx1000mm.

NOTE: The direction of the grain refers to the long side! Larger formats available on request.

The item is in stock

Dispatch within 2-3 working days

- Panels in Cut

- Request a sample

Request a free sample.

Dimensions of the samples approx. 200mm x 100mm

- at pieces 0,00 € (Base Price 0,00 € / m2)

- at pieces 0,00 € (Base Price 0,00 € / m2)

- at pieces 0,00 € (Base Price 0,00 € / m2)

All prices include 19% VAT.

0,00 € / pc.

0,0000kg / pc.

All prices include 19% VAT.

- Description

Composite aluminium panels with dark stained ash wood finish

Our aluminium composite panels in decorative wood look (dark stained ash) are available cut to size to the millimetre in a thickness of 3mm at particularly favourable prices. Aluminium composite panels basically consist of three individual panels that are inseparably joined during production to form a stable, rigid panel. A core of black polyethylene is used as the basis for the thickness of the panel. Solid aluminium with a thickness of approx. 0.3 mm is used for the surfaces, which serve as cover layers. This sandwich process makes it possible to achieve a significantly lower weight compared to solid aluminium panels. In addition, aluminium composite panels offer a very high inherent rigidity, which cannot be achieved at all by solid plastic panels without aluminium face sheets in the low thickness. These aluminium face sheets are given a high-quality stove enamel finish, the appealing wood look of which is based on the grain of dark-stained ash. The advantage of a stove enamelling is the very good scratch resistance and at the same time very good resistance to UV radiation and weathering. This means that our aluminium composite panels in wood decor can be used outdoors without hesitation.

The surfaces of the aluminium composite panels with wood look have a dark stained ash grain on both sides, so that the panels are also suitable for applications where the panel is to be used free-standing or visible from both sides. The grain is not only a weatherproof, insensitive stove enamelling, as is the case with our smooth aluminium composite panels in various colours, but also has a surface structure on the haptic side, so that the grain structure can be felt to give an even more valuable impression.

Our grained aluminium composite panels are equipped with a robust protective film made of polyethylene on both sides to protect the high-quality surfaces from scratches and damage that could possibly occur during processing of the panels. The protective film can be easily removed after processing or before bonding and recycled in the yellow recycling bin.

Standards of the aluminium composite panels with wood decor

- ISO 9001:2000 Requirements for the certification of quality management systems

- ISO 14000:2004 Environmental management systems - Requirements with guidance for use

- Manufacturing according to ASTM (international standardisation organisation)

- Manufacturing according to DIN (German Institute for Standardisation)

- REACH (EU Chemicals Regulation)

- RoHS (Ordinance on the Prohibition of Hazardous Substances in the Electrical Industry)

You can order our aluminium composite panels directly cut to your desired dimensions using our cut-to-size configurator.

The cutting is done on one of our modern panel saws for horizontal cutting. These CNC-controlled saws with laser measurement not only have extreme accuracy, but also guarantee a highly precise cutting edge thanks to two sawing passes with special saw blades. Thanks to extensive stocking of all the panels we offer for cutting, short delivery times are possible. The processing of the cuts usually takes place the day after the order is received, so that you can enjoy your cuts of aluminium composite panels in a timely manner.

NOTE: Please note that the grain structure of our aluminium composite panels in wood look always runs in the longitudinal direction (input field for length). This means that if the panel is cut to a length of 1000mm and a width of 600mm, the grain will run in the direction of the length of 1000mm from left to right. If, on the other hand, the grain is to run along the shorter side of 600mm, the entry must be made for the length 600mm, as well as for the width 1000mm.

Application examples for aluminium composite panels in dark stained ash

- The stable, hard-wearing panels are ideally suited as an alternative to a tiled backsplash in the kitchen

- The decorative composite panels are very well suited for large-area cladding in interior and exterior areas

- The lightweight aluminium composite panels in wood look are used for the interior finishing of caravans and motorhomes

- Aluminium is rustproof, so the panels can also be used as shower walls or in sanitary facilities

- In interior design, aluminium composite panels are often used as decorative cladding for furniture or as partition walls

- and many more

Processing of our grained aluminium composite panels in wood look

Aluminium composite panels are extremely friendly to work with and can be processed in every conceivable way. Very simple hand tools such as a circular saw, jigsaw or even a cordless screwdriver are usually sufficient for this. For cutting, we use very large panel saws in our house, which are similar to the principle of a table saw. This method is ideal for straight cuts, especially if the circular saw has a fence. For small cuts, cut-outs or the sawing of curves or other arbitrary shapes, a pendulum stroke jigsaw is perfect. When sawing, use a fine-toothed saw blade that is suitable for metals such as aluminium. When sawing, make sure that the speed or stroke rate is not set too high. This not only prolongs the life of the saw blade used, but also prevents the sawdust of the PE core from fusing with the cutting edge due to excessive heat development. Thanks to the low thickness of only 3 mm, as well as the core made of polyethylene plastic, the cutting can also be carried out very well with a hand-operated hacksaw or, for particularly filigree cuts, with a fret saw.

Milling with a CNC milling machine or a handy router offers another possibility to cut the lightweight panels into the desired shape. Milling also offers the possibility of rounding off the edges or chamfering the edges. Milling grooves at a 90 degree angle is also possible with a milling tool. This makes it possible to edge the aluminium composite panels very precisely in order to create decorative corner cladding or corner mouldings. With our milling service, we offer the possibility of milling the grained aluminium composite panels entirely according to your specifications on request. From edge processing, cut-outs and drill-holes to grooves for folding, almost no wish remains unfulfilled with our modern CNC 3-axis milling machines.

Aluminium composite panels can also be engraved very well with a milling machine or a laser. Although this process is used less frequently with Holzopzik decorative panels, it can also contribute to a high-quality and modern look thanks to the black PE core. For example, when they are used as information signs, door signs or decorative elements. Laser cutting, on the other hand, is only possible with aluminium composite panels using special laser systems with high laser powers, so laser cutting is rarely used to cut aluminium composite panels into any shape.

To fasten aluminium composite panels with screws or rivets, they should be pre-drilled with a suitable drill. Such drillings, as well as all other drillings, can be carried out easily with a standard cordless screwdriver. Due to the top layers of solid aluminium, we recommend HSS drills, as they are used for metal processing. In our online shop, we offer you the right drill bits in profile-ground quality in various diameters for the most diverse fastening solutions. Due to the ground drill tip, the drill slides smoothly through the aluminium cover layers even without knowing the drill hole positions in advance and ensures precise drill holes with perfect drill hole edges.

Aluminium composite panels can be bonded well with a silicone. With our extra strong MS polymer Parabond 600 in gray, which is characterised by a fabulous initial adhesion, the bonding of the decorative panels is even better. Especially when bonding to walls and ceilings, the significantly higher adhesive strength of the MS polymer is a great advantage compared to a conventional silicone sealant. As with all bonding, however, it is important to ensure that the panels are adequately fixed until the adhesive has cured. This is the only way to prevent the panels from slipping or falling off.

As an alternative to bonding with our assembly adhesives, we offer various other fastening solutions for our aluminium composite panels with wood finish on both sides in our online shop. For example, to match the brown surfaces, we offer head-lacquered facade screws made of stainless steel in brown for mounting on substructures made of wood, which are equally suitable for wall mounting with dowels in a thickness of 8mm. In addition, we also carry stainless steel balcony screws or high-quality facade rivets in various designs and colours at favourable graduated prices. It should be noted, however, that when fastening the panels with screws or rivets, they should be installed without any constraints. This is especially true if the panels are used outdoors and thermal expansion due to solar radiation cannot be ruled out.

NOTE: The aluminium composite panels are equipped with a protective film on both sides to protect the high-quality appearance of the surfaces from damage during transport or processing. However, this film can be removed very easily and should only be removed after processing, but before assembly by screwing or gluing.

- Additional Information

Additional Information

Product-ID 91 Weight 9.7050 Thickness 3 Standart Length 3050 Standard width 1220 Delivery Time Dispatch within 2-3 working days EAN/GTIN 4260604221225 Plastic Alu sandwich UV resistance UV resistant Color Brown Color accuracy Color similar to RAL color system Color designation Wood look (dark ash stained) - Reviews

- Attachments