Plexiglas® or acrylic glass - which is actually which?

Plexiglas® is always acrylic glass, but acrylic glass is not always Plexiglas. We at S-Polytec would like to explain what Plexiglas actually is.

In our shop, people very often look for Plexiglas® in different thicknesses and it is not uncommon for the phone to ring with the question of whether we can also offer Plexiglas®.

Some people seem to be unclear about what Plexiglas actually is, which is why we would like to shed some light on the subject at this point.

Plexiglas® or acrylic glass

Both are correct, because Plexiglas® is always also acrylic glass, but acrylic glass is not always Plexiglas®. Sounds confusing at first, but we are on the trail of the riddle.

What is Plexiglas®?

Plexiglas® is basically nothing more than a brand name and is often used synonymously for the actual product, just as the name Tempo® is often used when talking about paper tissues.

When one speaks of Plexiglas, however, it is usually not the brand as such that is meant, but the plastic acrylic glass, which stands for very high light transmission and a surface that is insensitive to scratches.

What is acrylic glass?

Acrylic glass is produced by the polymerisation of monomeric methyl methacrylate to polymethyl methacrylate, which is abbreviated to PMMA, and is offered on the market under a wide variety of brand names, including Plexiglas.

NOTE:Due to its chemical composition, acrylic glass is already UV and weather resistant by nature and can therefore be used without any problems indoors as well as for outdoor applications.

The high light transmission of acrylic glass, which at an average of 92% is even higher than the light transmission of conventional glass, makes acrylic glass a perfect substitute in all areas of application where glass is either too heavy or where the thermal properties of acrylic glass are exploited.

Acrylic glass belongs to the amorphous thermoplastics whose original colour is clear, transparent. This also applies to Plexiglas® because, as already mentioned, Plexiglas® is nothing more than a brand name for acrylic glass, the trademark patent for which is currently held by the company Evonik Röhm GmbH. Thermoplastics have the advantage that they can be shaped into almost any form under the influence of heat.

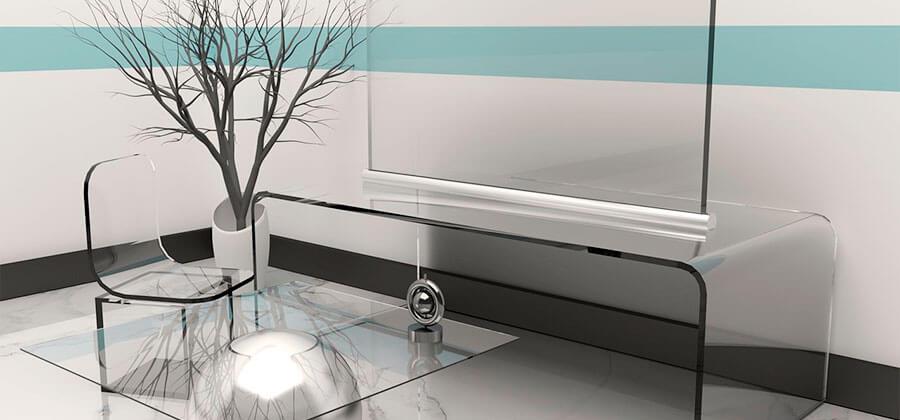

Through thermoforming, for example, acrylic glass can be used inexpensively, simply and efficiently for the production of transparent finished parts. These can be crystal-clear pieces of furniture such as chairs, or curved viewing windows or toys made of transparent plastic.

Due to its excellent optical properties, acrylic glass is also used to make lenses for objectives and microscopes. Spectacle lenses, on the other hand, are rarely made of acrylic glass, as acrylic glass, like glass, can break relatively quickly, so polycarbonate is usually used here.

In our online shop, we offer you our acrylic glass sheets cut to the exact millimetre at favourable prices. You can choose from different thicknesses from 2.0mm up to 10mm. With our easy-to-use cut configurator, you can freely choose your desired dimensions from 30mm by 30mm up to 2000mm by 1000mm. The whole thing can be done conveniently online from home.

On request, we are also able to supply larger formats or other thicknesses of our acrylic sheets.

NOTE:Plexiglas® is a registered brand name of Evonik Performance Materials GmbH. Tempo® is a registered brand name of SCA Hygiene Products AB, Gothenburg/Gotenburg, SE.