Special gauge mouthpiece HPL-16

The special gauge mouthpiece HPL-16 is suitable for riveting HPL panels with our Ø 16mm aluminium facade rivets. The special tool is used for the assembly of sliding point fasteners and guarantees the perfect gap distance of 0.3mm.

✓ For HPL and fibre cement panels

✓ For Ø 16mm aluminium facade rivets

✓ For constraint-free riveted joints

✓ Perfectly coordinated gap distance

✓ Extremely compact design

✓ M10 threaded receptacle

The special gauge mouthpiece is compatible with all common riveting tools with M10 thread receptacle.

The item is in stock

Dispatch within 2-3 working days

- calculate the price

€55.95 / pc.

0,0300 kg / pc.

All prices include 19% VAT.

- Description

- Additional Information

- Reviews

- Description

Special gauge mouthpiece HPL-16 for HPL facade panels

For aluminium facade rivets with Ø 16mm ✓ For constraint-free installation ✓

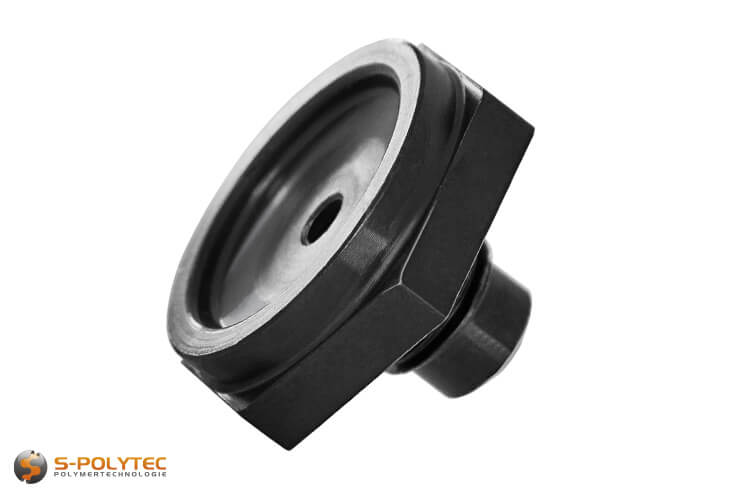

Our special gauge mouthpiece type HPL-16 is used for the production of rivet joints in the constraint-free assembly of HPL panels with our aluminium facade rivets. With a thread of size M10x1, the special gauge mouthpiece is compatible with all commercially available riveting tools that have a standard thread receptacle of size M10.

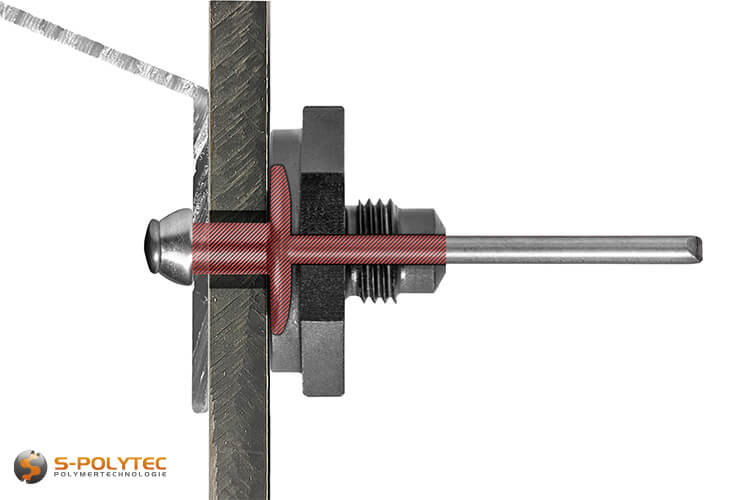

Our special gauge mouthpiece for HPL panels has a head receptacle for facade rivets with a diameter of 16mm. This receptacle is precisely matched in shape to our aluminium facade rivets and guarantees that the perfect gap distance of 0.3mm is always maintained when riveting. The very small clearance is absolutely necessary for sliding point fasteners for facade panels made of HPL laminate or fibre cement, so that the panels can expand from the fixed point. Due to the compact design, riveted joints close to the edge are also possible without an excessively large contact surface hindering the placement of the mouthpiece. Due to the very hard surfaces that are given with high-pressure laminates or fibre cement, large contact surfaces are also not necessary.

Scope of delivery:

- 1 x special gauge mouthpiece type HPL-16

NOTE: In order to be able to use the special gauge mouthpiece, a commercially available riveting pliers with M10 thread receptacle is required.

Technical data of the special gauge mouthpiece type HPL-16

- Name: Type HPL-16

- Material: Hardened steel

- Ø Mounting thread: M10

- Ø Mouth piece: ca. 23mm (SW 24)

- Ø Rivet head: 16,0mm

- Ø Rivet shaft: 5,0mm

- Material Rivet: : Aluminium

- Mounting type: Slide point assembly

- Gap distance: ca. 0,3mm

- Building material: HPL panels, fibre cement panels

Application restrictions for the special gauge mouthpiece HPL-16

A special gauge mouthpiece is a special tool that is screwed into commercially available riveting tongs to produce rivet joints for very specific materials. The materials and rivets for which a special gauge mouthpiece is suitable depend on the design and must be strictly observed in order to carry out the installation correctly according to the applicable standards.

The special gauge mouthpiece type HPL-16 is specially adapted to the materials HPL and fibre cement, for which a constraint-free assembly is absolutely necessary when these are used as cladding panels. It makes no difference what manufacturer the panels are from or what their material thickness is. Thus, our own HPL panels as well as Trespa® panels or facade panels from Kronoplan, Fermacell or Eternit can be riveted with the HPL-16 mouthpiece. However, the special tool cannot be used for plastic panels made of other materials.

Furthermore, the special gauge mouthpiece is only compatible with special facade rivets. These must be made of aluminium with a head diameter of 16mm, as is the case with our facade rivets. The rivet shank, often referred to as the rivet sleeve, is also crucial. Here too, the material must be made of an aluminium alloy and have a nominal diameter of 5mm. The length of the rivet sleeve, on the other hand, can be chosen as desired and is only limited by the clamping area, which is defined by the thickness of the HPL panels and the material thickness of the aluminium substructure. Whether the facade rivets are unlacquered or have a head lacquer that matches the panel surface has no effect on the usability of our special gauge mouthpiece.

Application instructions for the special gauge mouthpiece HPL-16

For riveting facade panels made of HPL and fibre cement to aluminium profiles, such as our Z-profiles or omega profiles , a constraint-free assembly is a prerequisite to ensure thermal expansion of the panels without bulging. In this case, a riveted joint must be defined as a fixed point and all remaining fastenings of a single panel serve as sliding points for which the special gauge mouthpiece is required.

Before the installation of the facade panels can begin, both the substructure profiles and the panels must be drilled at the desired fastening positions. The profiles, as well as the hole for the fixed point of a panel, must be drilled with a diameter of 5.1mm so that the rivet sleeve can create a secure, firm connection when riveting. All other holes in the panel require larger hole diameters of at least 8mm up to a maximum of 10mm. The larger holes are easily covered by 16mm facade rivets and are necessary to allow the panel to expand on all sides. For this to be possible, the rivet joints of the sliding points must not be too tight. With our special gauge mouthpiece, the gap distance of 0.2mm necessary for HPL is guaranteed.

Our special gauge mouthpiece HPL-16 can simply be screwed into the threaded receptacle of the riveting tool and is thus immediately ready for use. To avoid surface damage to head-lacquered rivets or the facade panels, the nose piece should be checked for damage, indentations or contamination before each use and cleaned if necessary.

NOTE: If the surfaces of the facade panels are equipped with a protective film, this must be removed at the appropriate points before placing the rivets.

- Additional Information

Additional Information

Product-ID AFN-SLM-AG03 Delivery Time Dispatch within 2-3 working days EAN/GTIN 4260604223779 Material hardened steel Weight 0.0300 - Reviews