PE-EL sheets black 2x1meter (electrically conductive, UV-stabilised)

Electrically conductive polyethylene sheets (PE-EL) in black are available as UV-stabilised standard sheets in the format 2.0x1.0 metres in the thicknesses: 3mm, 4mm, 5mm, 6mm, 8mm, 10mm, 15mm, 20mm, 25mm, 30mm, 40mm and 60mm. The solid PE sheets with electrical conductivity are used in potentially explosive areas - Made in Germany.

The item is in stock

Dispatch within 7 - 10 working days

- Standard panels

- at pieces 0,00 € (Base Price 0,00 € / m2)

- at pieces 0,00 € (Base Price 0,00 € / m2)

- at pieces 0,00 € (Base Price 0,00 € / m2)

All prices include 19% VAT.

0,00 € / pc.

0,0000kg / pc.

All prices include 19% VAT.

- Description

PE-EL sheets - electrically conductive - UV-stabilised!

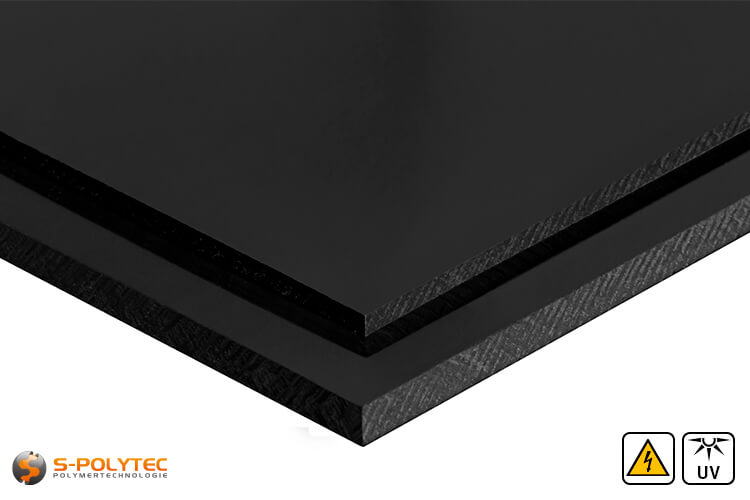

Our PE-EL sheets in black are made of electrically conductive polyethylene and are available as standard sheets in thicknesses from 3.0mm to 60.0mm. The dimensions of our standard PE-EL sheets in black are 2000mm in length and 1000mm in width. In order to be able to guarantee a consistent black colour on the surfaces, as well as on the cut and milled edges, our PE-EL sheets are dyed completely black. Our conductive plastic sheets made of polyethylene are manufactured in Germany and consist of 100% virgin material. The solid sheets do not contain a foamed polyethylene core and have black, smooth surfaces that are protected from scratching by a protective film on one side, depending on the thickness.

Our PE-EL sheets made of electrically conductive polyethylene have a protective film on one side up to a thickness of 20mm to prevent the surfaces from being scratched before and during processing. Sheet thicknesses over 20mm do not have a protective film.

NOTE: Our black PE-EL sheets, are considered engineering plastics, and are therefore not recommended for use for optical purposes.

Properties of our conductive polyethylene sheets in black

PE-EL is a highly heat-stable and UV-stabilised plastic with electrical conductivity. This means that PE-EL can be used in chemical container and apparatus construction as well as excellently in the electrical industry and all other potentially explosive areas. This applies in particular to areas of application where electrostatic charging can occur due to friction caused when dust or a liquid flows past the plastic surfaces. An uncontrolled discharge due to sparking can lead to ignition of flammable substances (gases, liquids or solids that form an explosive atmosphere with air), which is prevented by discharging the electrostatic charge.

NOTE: Our plastic sheets made of electrically conductive polyethylene are not suitable as electrical conductors, but only serve the purpose of preventing uncontrolled electrostatic discharge by dissipating the electrical charge. For this reason, the plastic sheets made of PE-EL must be properly and sufficiently earthed in order to comply with the ATEX regulations.

The excellent resistance to chemicals such as most (also concentrated) acids, alkalis or solvents, which is typical for polyethylene, as well as the very good sliding properties and high corrosion resistance, also apply to the electrically conductive version PE-EL in black. Therefore, these plastic sheets are used in particular in the chemical industry, as well as in all areas where good chemical resistance is required, which must also comply with the EU Directive RL 2014/34/EU (Directive of the European Parliament for equipment and protective systems intended for use in potentially explosive atmospheres (new version)). This applies, for example, to the animal feed industry, port facilities, sewage treatment plants, refineries or paint factories.

The black PE-EL sheets are UV-stabilised and are therefore suitable for both indoor and outdoor applications. The temperature range is from -20°C to +80°C.

Standards for our PE-EL sheets in black

Plastic sheets made of PE-EL are not approved for use in contact with food because they do not comply with approvals according to food conformity according to FDA or according to EU 10/2011.

- REACH (EU Chemicals Regulation)

- RoHS (Regulation on the Prohibition of Hazardous Substances in the Electrical Industry)

- PAK (Directive on compliance with limit values for polyaromatic hydrocarbons)

Other thicknesses or sizes of sheets made of electrically conductive PE-EL are available on request

Our plastic sheets made of PE-EL with electrically conductive properties are available in our online shop with a standard format of 2000mmx1000. However, larger standard sheets with a format of 3000mmx1500mm as well as other thicknesses of the electrically conductive polyethylene sheets are also available on request.

Application examples for our PE-EL sheets in black

- Containers and linings for inflammable filling materials are made of electrically conductive PE-EL

- For the filling and storage of powdery materials, the often conductive polyethylene is used

- Thanks to its conductivity, PE-EL is suitable for containers and machine parts in explosion-protected rooms

- Conveyor belts or slide rails with a high electrostatic charge are made of PE-EL

- and many more

Processing of our PE-EL sheets in black

The electrically conductive polyethylene in black, like all our solid polyethylene sheets, can be processed excellently with simple woodworking tools and so cuts of the 2.0x1.0 metre standard sheets can be easily sawn or milled without special machines. Cutting to size can also be done with a water jet cutting machine. The production of semi-finished products with a punching machine, as well as the turning or drilling of our PE-EL sheets are also possible processing methods that are frequently used.

The thermoforming process is common practice for the industrial production of finished plastic parts made of electrically conductive PE-EL in black. In addition, PE-EL can be hot-formed or cold-formed without further ado. However, it should be noted that the protective film (applies to our standard sheets up to 20mm thick) cannot be thermoformed and must be removed before thermoforming.

PE-EL has the excellent chemical resistance of polyethylene and for this reason cannot be printed, painted or glued. The solvent resistance of the anti-adhesive plastic also contributes to the fact that the black PE-EL cannot be glued with conventional plastic adhesives. In order to bond polyethylene nevertheless, we offer you the special PE adhesive S-Polybond PEprofi. This two-component adhesive from our own production was specially developed for bonding polyethylene, but is not electrically conductive.

Welding polyethylene is common practice to create a secure and permanent connection between the electrically conductive PE sheets. We can supply you with the matching PE-EL welding rod in black, which also has electrically conductive properties, on request. PE-EL can also be riveted or screwed for simple connections with PE-EL or other materials, for example to provide the necessary earthing to dissipate the electrostatic charge.

NOTE: As an engineering plastic, our PE-EL recycling sheets are only suitable for optical purposes to a limited extent and are supplied with a protective film on one side up to a thickness of 20mm and without a protective film for thicker sheets.

- Additional Information

Additional Information

Product-ID 63220S Standard width 1000 Standart Length 2000 Thickness No Delivery Time Dispatch within 7 - 10 working days Plastic Polyethylene Material PE-EL UV resistance UV stabilized Color Black Color accuracy Color similar to RAL color system RAL color code RAL9005 Color designation Jet black - Reviews

- Attachments