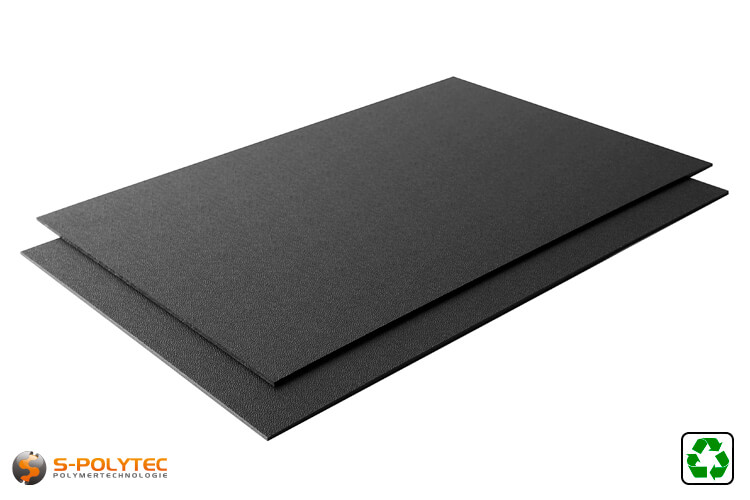

PE-HD recyclate black grained custom cut

Polyethylene sheets (PEHD Reclaim) in black with grained surface on one side can be purchased cut to size at very low prices. The recycled sheets with a one-sided medium grained surface are available in 2mm to 5mm thickness. 100% recycled material ✓ 100% quality Made in Germany ✓

The item is in stock

Dispatch within 2-3 working days

- Panels in Cut

- Request a sample

Request up to three free samples.

Dimensions of the samples approx. 200mm x 100mm

- at pieces 0,00 € (Base Price 0,00 € / m2)

- at pieces 0,00 € (Base Price 0,00 € / m2)

- at pieces 0,00 € (Base Price 0,00 € / m2)

All prices include 19% VAT.

0,00 € / pc.

0,0000kg / pc.

All prices include 19% VAT.

- Description

PE-HD sheets made of recycled material with graining on one side when cut to size

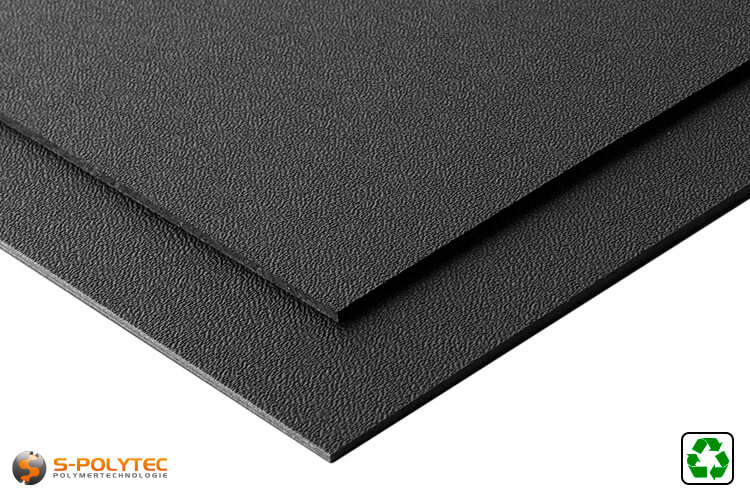

Our PE-HD sheets in black, made of recycled material (regenerated) with a grained surface structure on one side, are available in the thicknesses 2mm to 5mm as cut to size with millimetre precision. The sheets are made of solid PE plastic without a foam core and are completely dyed through in black. This ensures that the colour of the surfaces and cut edges is identical. The colour tone is very similar to the RAL colour jet black (RAL9005). The one-sided surface structure has a medium grain, which is visually reminiscent of the structure of leather. On the other side the surface is smooth. The PE-HD degranulates in cut-to-size are delivered without protective film.

PE-HD Regenerated grained - buy cut to size online

With our cutting service we offer you the possibility to order our recycling boards in millimetre-precise cuts very easily and at a reasonable price according to your needs. For this purpose we offer you our PE-regenerates in the thicknesses 2mm to 5mm up to a format of 2000mmx1000mm. Simply enter the desired dimensions for length and width in the corresponding input fields, making sure that the values are entered in millimetres (not centimetres). Our price calculation takes place in real time and automatically calculates quantity discounts based on the total weight of your cut-to-size sheets to ensure you always get the best possible, low-cost price.

NOTE: If you require our PE-HD regenerates with one-sided surface graining in other thicknesses, we can also have them produced directly in your desired thickness. Please note, however, that a minimum weight of 500kg per thickness is required.

We always have very large quantities of our plastic sheet made of PE-HD regenerated in our warehouses and, thanks to the high production volume, can fall back on favourable purchase prices from our extruder. A further aspect for our very favourable prices is that we use our own recycling waste made of pure polyethylene for the production of our recycled sheets. Due to the high storage volume of all available thicknesses, very short order processing times are also possible, so that the cut-to-size panels are usually sawn to your desired dimensions on the next working day after receipt of your order and are then handed over to the shipping department. Depending on the size and total weight of your order, shipping is then carried out by a parcel service or a forwarding agent.

Characteristics of our black PE regenerates with surface graining

Our PE regenerates are made of 100% recycled PE-HD material

Plastic sheets made from recycled material have comparable properties to our PE sheets, which are made from new raw materials. Starting with the temperature resistance from -50°C to +80°C, through the physical density of 0.96 g/cm3, the values are identical. The typical properties of PE, such as the good sliding properties, the very high impact resistance or the very good chemical resistance, naturally also apply to the recycled sheets. In addition, the regenerated PE sheets are also hydrophobic, which means that the sheets do not absorb moisture from the environment and can therefore be used as waterproof plastic sheets even when in permanent contact with or under water. However, polyethylene is a plastic with a lower surface hardness, so that it is mainly used for technical applications. Due to the one-sided structured surface with medium grain size, slight scratches are hardly noticeable, so that the sheets can also be used for optical purposes. As an alternative to the one-sided grained PE sheets, we also offer black PE-HD sheets cut from virgin material with a smooth surface on both sides in many thicknesses from 2mm to 25mm. However, these are made from virgin material and not from recycled PE-HD plastic waste.

Regenerates are much cheaper and protect the environment!

Polyethylene sheets made from recycled material have two significant advantages. On the one hand, the expensive and time-consuming extraction of raw materials, e.g. crude oil, can be dispensed with when using recycled material, because everything that is required for the production of a recycled panel is already contained in the recycled material. This means that regenerates are significantly cheaper than comparable plastic sheets made from virgin material. The second, no less important aspect is that less plastic waste is thermally recycled in incinerators or disposed of in other ways, but can be processed into a new high-quality product by melting and extrusion, which not least has the effect of improving the climate balance.

Due to perfect cuts in your desired size there is no waste!

We offer you our PE-HD sheets as regenerates in exact cut to size, so that you can order your plastic sheet cuts online directly in the size you need. This not only saves you time for cutting the standard sheets to the required size, but also money, because we only charge you for the cut-to-size sheets based on weight. Any off-cuts are used in the best possible way for further cuts or for recycling.

Application examples for PE-HD sheets from regenerated material

In very many cases, it is possible to dispense with the use of polyethylene sheets made from virgin material and instead fall back on PE-HD regrind without this having a negative effect on the intended use. The properties of the recycled sheets are comparable to sheets made of virgin material, because they are the same plastic with all its specific advantages and disadvantages, which are typical for polyethylene.

As an impact-resistant plastic, polyethylene is perfect for protecting walls and vehicles in garages, warehouses or production halls with forklift traffic. When using recycled sheets made of PE-HD, this is not only an extremely cost-effective alternative to impact protection made of PE-HD virgin material, but also contributes to the fact that fewer plastic sheets have to be produced from virgin material. The grained surface of our black recycling panels not only looks better than conventional smooth panel surfaces. Even small scratches or bumps are less noticeable due to the surface structure.

The inexpensive plastic can be used very well as a base on pallets, or also for the production of support structures for machine components and covers. Due to the carbon black content for colouring, which causes the deep black colour of the regenerated material, the plastic sheets are UV-stabilised, which makes them suitable for outdoor use. This makes the PE-HD sheets made of recycled material ideal for flat cladding or for root protection sheets and lawn edge barriers.

Polyethylene is also characterised by very good sliding properties and very good chemical resistance (e.g. acids, alkalis, solvents) and is therefore the perfect plastic for machines and systems in conveyor technology. However, since it can never be completely ruled out that particles of foreign plastics are contained, the recycling sheets do not have food approval compared to PE plastic from virgin material, so that the sheets should not be used for conveyor belts with direct food contact. However, this restriction does not apply to repackaged food, so that here too, the cheaper regenerated sheets can be used.

- PE-HD regenerated sheets are perfect for the inexpensive construction of lawn edge barriers and root protection

- PE regenerates are excellently suited as wall and impact protection in garages and warehouses with forklift traffic

- For disposable products, e.g. as plant trays, regenerates are a cost-effective and environmentally friendly alternative

- The grained panels are ideal for impact-resistant cladding and machine covers with an attractive appearance

- and much more.

Processing of PE regrind with grained surface

Cutting PE-HD regrind to size

Even if it should not be necessary to cut the PE-HD sheets to size due to our high-precision cutting service, the sheets can be cut to size excellently by almost all common methods. All machining processing methods are available to you, as they are also used in wood processing. Cutting can be done by sawing, milling, planing or even grinding. Very small thicknesses can also be cut very well with a cutter knife. When sawing or milling, however, make sure that the feed rate is low and that the speed is not too high to prevent excessive heat development. This prevents the sawdust from melting with the cutting edge. In addition, the plastic sheets can also be cut to the desired size or shape with a CO2 laser or a water jet cutting machine. The required laser power or water pressure depends on the selected thickness of the recycling boards.

Note: Protect the environment and buy grained polyethylene sheets made of black recycled material directly online in your desired size.

Drilling PE-HD regrind

The drilling of holes, e.g. for screwing the PE plates or for the production of perforated plates, is very easy to carry out. A standard cordless screwdriver with a metal drill in the desired size is sufficient for this. As with sawing, the speed of rotation should not be too high when drilling. Also, you should not exert too much pressure on the drill bit when drilling, in order to avoid chipping when the drill bit exits.

Bonding PE-HD regrind

Polyethylene is chemically very inert and resistant to solvents. Therefore, this plastic cannot be bonded with conventional adhesives, as the surface cannot be dissolved by the adhesive. Our sheets made of regenerated PE are no exception. However, with our Polyethylene adhesive S-Polybond PEprofi we offer you a reliable 2-component adhesive of our own brand, which has been specially developed for bonding polyethylene. It is not only suitable for bonding polyethylene from virgin material, but also for bonding virgin material with regrind or regrind with each other.

Thermoforming PE-HD regrind

Thermoforming of polyethylene is a very common method for the production of finished plastic parts made of polyethylene. However, thermoforming is only recommended to a limited extent for PE sheets made of recycled material. Although only pure recycled material is used for our regrind, which is subject to strict quality controls, it can never be 100% guaranteed that it contains very small amounts of foreign plastics, which can affect the optical and technical quality of the finished part, especially when the aspect ratio is high or the thickness of the sheet is low.

Nevertheless, regenerated materials are also very often thermoformed if the products are not subject to high demands on appearance or mechanical strength. A good example are plant trays for transporting several plant pots on a pallet. By using regenerates, such disposable products can be manufactured at a much lower cost and at the same time protect the environment, as they can be recycled after use.

Note:We do not assume any warranty if the recycling sheets made of PE plastic are processed in a deep-drawing process.

Disposal of recycled sheets made of grained PE-HD

Polyethylene can be excellently recycled to produce new plastic sheets from the blanks of our plastic sheets that are no longer needed by cleaning, shredding, grinding and melting them down. This also applies to plastic sheets that have already been produced from recycled material. This process can be repeated almost as often as required, so that the extraction of raw materials can be dispensed with in the long term.

The disposal of waste in normal household quantities can be done via the yellow recycling bag or the recycling bin. Larger quantities of PE waste may be sold to interested extruders or recycling companies. It is important, however, that the PE residues are collected separately and do not contain any foreign plastics or heavy impurities, so that the best possible quality of the regenerated material is guaranteed.

NOTE: Our black plastic sheets made of recycled PE material are delivered without protective film. For this reason, we recommend a careful approach to processing and handling, even if minor scratches are hardly noticeable due to the grained surface.

- Additional Information

Additional Information

Product-ID 60920C Thickness 2 - 5mm Standart Length 2000 Standard width 1000 Delivery Time Dispatch within 2-3 working days Plastic Polyethylene Material PE-HD Recyclate (recycling material) UV resistance not UV resistant Color Black Color accuracy Color similar to RAL color system RAL color code RAL9005 Color designation Jet black - Reviews

- Attachments