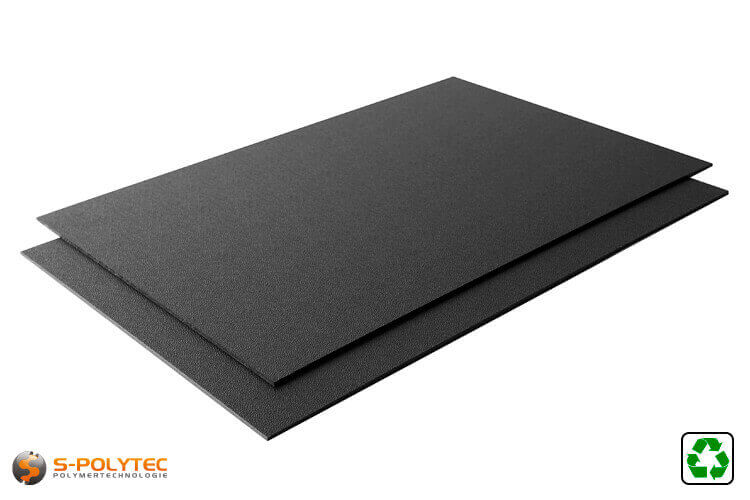

PE-HD Regenerate black grained on both sides cut to size

Buy polyethylene sheets cut to size from PE-HD reclaimed material in black with a grained surface on both sides at rock-bottom prices. The recycled sheets with a medium grain are available in thicknesses of 10mm and 15mm and are made from 100% recycled material - 100% quality Made in Germany ✓

The item is in stock

Dispatch within 2-3 working days

- Panels in Cut

- at pieces 0,00 € (Base Price 0,00 € / m2)

- at pieces 0,00 € (Base Price 0,00 € / m2)

- at pieces 0,00 € (Base Price 0,00 € / m2)

All prices include 19% VAT.

0,00 € / pc.

0,0000kg / pc.

All prices include 19% VAT.

- Description

PE-HD reclaimed material cut to size grained on both sides

100% Polyethylene ✓ 100% Recycling material ✓ 100% Made in Germany ✓

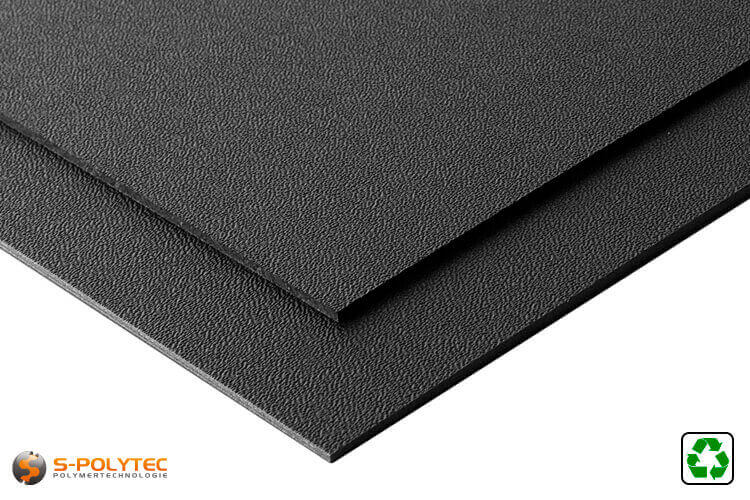

Our PE-HD reclaimed sheets in black made from 100% recycled material are available cut to size up to 2000 x 1000mm. The sheets with a thickness of 10mm or 15mm have a grained surface with a medium grain. In contrast to our grained PE recycled sheets in lower thicknesses, the surface is not only grained on one side, but on both sides. The solid sheets in deep black are completely dyed through. The cut edges and surfaces therefore have the same colour tone, which roughly corresponds to the RAL colour deep black (RAL 9005).

Benefit twice over - save time and money with our cutting service!

We make it as easy as possible for you with our cutting service, as we cut the black recycled panels to the size of your choice. We offer very high dimensional accuracy with a maximum deviation of one millimetre. Thanks to our state-of-the-art panel saws for horizontal cutting, even very small cuts of 30 mm x 30 mm are possible. The maximum format for our panel cutting is based on the standard format and is limited to 2000mm x 1000mm. This saves you the time needed to cut the panels to size and the resulting waste does not have to be disposed of, nor is it charged for. So you only pay for what you need.

Properties of our black PE recycled sheets made to measure

The polyethylene sheets are made from 100% unmixed recycled material, meaning that the properties of a reclaimed material are completely comparable to those of a new sheet. The key properties of the plastic include very good impact resistance, which means that even very hard impacts do not cause the sheet to break, and extremely good chemical resistance, which proves to be excellent for use in industrial plants, machinery and construction equipment, especially against solvents, oils, greases and fuels. As a waterproof sheet that does not absorb moisture even when used permanently in and under water, the solid recycled sheets are also ideal for protection in shipyards, lock systems and harbour basins.

The temperature resistance ranges from -50°C to +80°C and is therefore not only identical to virgin PE-HD, but also sufficient for all areas of application in which this material is usually used. As an engineering plastic with a comparatively low physical density of 0.96 g/cm3 PE tends to scratch very easily. In contrast to smooth sheet surfaces, on which even small scratches become visible quite quickly, slight scratches within the grained surface are not so easily noticeable, so that the sheets can also be used for optical purposes for separators between industrial plants or for machine housings. As an alternative to the recycled panels with graining on both sides, we also offer Black PE-HD sheets made to measure from virgin material in many different sheet thicknesses, but which no longer have the grained surface structure and have a smooth surface on both sides.

Recycled boards are doubly useful - significantly cheaper and better for the environment!

In general, our plastic sheet cuttings already have the decisive advantage that hardly any plastic waste is produced due to the software-controlled cutting optimisation, which has a positive effect on the careful use of resources. The use of recycled material significantly increases this factor even further, as the sheets are made of 100% PE plastic, which is recycled, cleaned, shredded, ground and extruded into a homogeneous sheet in a complex process. In direct comparison to the extraction and processing of the raw materials, this process requires significantly less energy, which also has a positive effect on the carbon footprint.

The fact that you can also use the option of precise sheet cutting for our PE-HD reclaimed sheets to size means that you do not have to deal with the offcuts, but can use them for further cutting, which is reflected in a very favourable price for your offcuts, as you are not charged for the offcuts. In the case of very unfavourable cuts, where offcuts cannot be reused, we use our many years of experience in the recycling industry and return the offcuts to the recycling cycle so that new panels can be produced from them again.

Application examples for PE-HD reclaimed material in high thickness.

For most areas of application in which polyethylene is the perfect plastic, a cut from recycled material can be used without hesitation, because as explained in the plastic properties, pure regenerates have identical properties with all the advantages and disadvantages of sheets made from virgin material. From a purely economic point of view, it even makes sense to opt for the recycled version of polyethylene, as it is significantly cheaper in direct comparison.

As an impact-resistant plastic, polyethylene is perfect as a base on workbenches and in workshops. The sheets are also popular for wall mounting as impact protection. In the garage at home, effective protection of the garage wall and vehicle paintwork can be achieved in a simple way. For example, if the vehicle door is opened carelessly. In haulage companies and industrial sectors with forklift traffic, the panels are also used as impact protection to protect hall walls, passageways and machine partitions. Such a solution is simple and, thanks to the inexpensive regenerates, also very cost-effective to realise.

With a thickness of 10 mm or 15 mm, the quite strong sheets are also very popular in gardening and landscaping. While thinner thicknesses of plastic are also suitable for lawn edging and bed borders, thicker sheets are recommended for the strong roots of large shrubs and trees in order to divert the spread of roots downwards. The slabs are also used for this purpose in road construction to prevent damage to roads caused by tree roots by edging them towards the road and pavement with root protection slabs to prevent them from spreading.

Polyethylene is considered a favourable and universal plastic in all branches of industry and is used in large production lines, not least due to its excellent sliding properties in conveyor technology. These include production companies for the manufacture of tools, furniture manufacturers, the textile industry and the automotive industry, to name just a few examples. The only relevant restriction on the use of recycled PE is in the area of food processing and even here only for specific areas where direct contact between food and plastic cannot be ruled out, because due to the recycling process, in which minor impurities cannot be ruled out despite all precautions and care, regenerates are not food compliant. However, this restriction does not apply to the outer packaging of foodstuffs or to the conveyor technology of already packaged foodstuffs, meaning that the cheaper reclaimed sheets can also be used here.

- The high thickness of the solid reclaimed wood panels makes them ideal for root barriers for trees and shrubs

- The impact-resistant panels are perfect as impact protection in the garage to protect the garage wall and car

- The double-sided grain is also visually suitable for partitions between machines and systems

- The thick PE sheets are used in workshops as a durable impact base with high breaking strength

- and many more

Processing of polyethylene sheets with grained surface

Cutting PE-HD recycling sheets to size In most cases, there is no need to cut our PE recycled sheets to size, as they can be configured and ordered directly in the desired size. However, there are always reasons why further processing of the cut-to-size sheets is necessary, for example to cut out areas within the sheet. Due to the material thickness of 10 mm or 15 mm, cutting to size is most likely to be carried out using machining methods. These include sawing or routing. Regardless of which tool is to be used, the choice of a suitable saw blade or router bit is crucial. A medium toothing leads to the best result, as coarse saw blades for cutting wood are too coarse and metal saw blades are too fine, meaning that they very quickly become too hot. However, heat should be avoided with thermoplastics so that the chip does not fuse with the cutting edge. A low speed and a lower feed rate can help to prevent the cutting edges and the tool from heating up too much.

NOTE: With our PE regenerates, you save valuable raw materials and thus contribute to environmental protection.

Drilling PE-HD recycling sheets PE is a less brittle plastic that can be drilled very well with a simple drill bit. A commercially available HSS drill bit or, for those who want the perfect drill bit, a plastic drill bit with a smaller point angle - also known as an HK drill bit - is perfect for such purposes. It should be noted, and this applies to all drill holes in thermoplastics, that high heat build-up on the drill bit should be avoided. However, this is very easy to put into practice by drilling at a lower speed so that the drill hole edges are precise and sharp and the drill chip does not melt on the hot drill bit.

Bonding PE-HD recycled sheets Bonding polyethylene, whether virgin or recycled, is an art in itself. The reason lies in the chemical resistance, especially the resistance to solvents, so that the recycled sheets cannot be bonded with simple adhesives. This applies both to the bonding of PE to each other and to other material surfaces. Special adhesives are required here, such as our Polyethylene adhesive S-Polybond PEprofi. This is a 2-component adhesive that has been specially developed for bonding polyethylene. However, this adhesive is not only suitable for bonding polyethylene from virgin material, but also for bonding virgin material to regenerates or regenerates to each other, as well as for bonding to other materials (except PTFE, Teflon).

Technical data of our PE-HD recycled sheets in deep black

- Material: Polyethylene regenerate (PE-HD, recycled material)

- Colour: Black (similar to RAL9005, deep black)

- Surface: Grained on both sides (medium grain)

- Physical density: 0,96 g/cm3

- Modulus of elasticity: 1100 MPa according to DIN EN ISO 527

- Impact strength: Without breakage according to DIN EN ISO 179

- Notched impact strength: 16 kJ/m2 According to DIN EN ISO 179

- Shore hardness: 65 according to DIN EN ISO 868

- Food conformity: No

- Temperature resistance: -50 °C to +80 °C

- Chemical resistance: Excellent

- Fire behaviour: B2 (normally flammable) according to DIN 4102

- UV-resistance (colour): UV stabilised

Disposal of cut-to-size PE-HD recycled sheets

As single-origin plastic, the recycled sheets can be recycled again very easily when not in use, as can offcuts through further processing, and processed into new plastic sheets. Larger quantities can be purchased by specialised recycling companies, but smaller residual pieces are less lucrative to buy from an economic point of view, so it is advisable to dispose of them in the recycling bag or yellow bin so that the plastic can be professionally recycled together with other PE packaging in this way.

NOTE: The recycled panels are supplied without a protective film. However, small scratches caused by carelessness during further processing of the blanks are hardly noticeable thanks to the grained surface on both sides.

- Additional Information

Additional Information

Product-ID 60921C Thickness 10 - 15mm Standart Length 2000 Standard width 1000 Delivery Time Dispatch within 2-3 working days Plastic Polyethylene Material PE-HD Regenerat (Recyclingmaterial) UV resistance not UV resistant Color Black Color accuracy Color similar to RAL color system RAL color code RAL9005 Color designation Tiefschwarz - Reviews

- Attachments