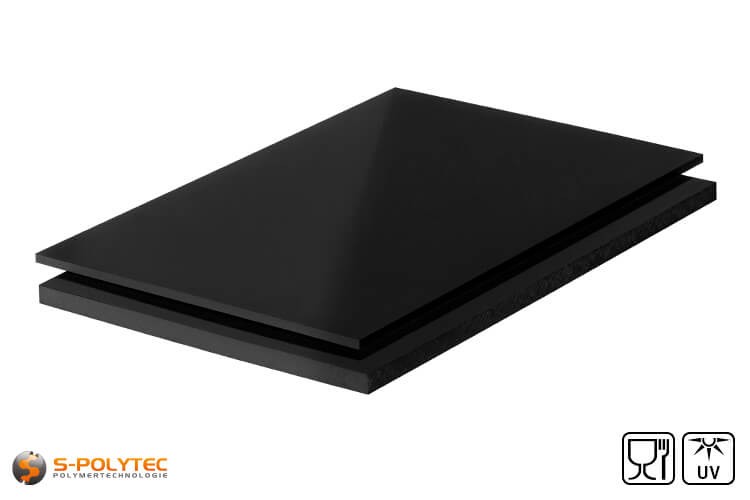

PE-HMW (PE-500) sheets black 2x1meter

Buy PE-HMW (PE500) sheets in the colour black as standard sheets in the format 2.0x1.0 metres in the thicknesses: 10mm, 15mm, 20mm, 25mm, 30mm, 35mm, 40mm, 50mm, 60mm, 80mm, and 100mm conveniently online at low prices. Our sheets made of high-molecular-weight, high-density polyethylene (PE-HD-HMW) consist of 100% virgin material - Made in Germany.

The item is in stock

Dispatch within 7 - 10 working days

- Standard panels

- at pieces 0,00 € (Base Price 0,00 € / m2)

- at pieces 0,00 € (Base Price 0,00 € / m2)

- at pieces 0,00 € (Base Price 0,00 € / m2)

All prices include 19% VAT.

0,00 € / pc.

0,0000kg / pc.

All prices include 19% VAT.

- Description

PE-HMW (PE500) sheets in black - high molecular weight!

Impact-resistant ✓ UV-stabilised ✓ Made in Germany ✓

Our PE-HD-HMW in black (also known as PE-HMW or PE500) is available in a standard size of 2000mmx1000mm in thicknesses from 10mm to 100mm. Made from solid core material with no foamed polyethylene core, the sheets are fully dyed throughout to ensure the same black colour on the surfaces and cut edges. Our PE-HMW sheets are manufactured in Germany and are 100% virgin material. The surfaces of the black PE-HMW sheets are smooth and are delivered without protective film.

NOTE: Polyethylene is an engineering plastic and as such is not recommended for use for optical purposes.

Properties of our PE500 sheets in black

PE-HD-HMW is the abbreviation for polyethylene - high density - high molecular weight and consists of polyethylene with high density and long molecular chains. Compared to our sheets made of PE-HD (high density polyethylene), PE-HMW is characterised by its even higher impact strength and increased abrasion resistance. Among other things, this results in better scratch resistance and cutting resistance compared to PE-HD sheets. In addition, the lower abrasion leads to better sliding behaviour and significantly increased wear resistance. This makes PE-HMW valuable for all areas of application in which low wear and good sliding properties are required, as is the case in mechanical engineering or in the conveyor technology of industrial plants.

Another advantage of PE-HMW is the increased temperature range, which extends from -100°C to +80°C. With normal PE-HD sheets, the temperature range is only -50°C to +80°C. The increased impact strength in combination with the resistance to very low temperatures is used especially in cold storage construction and refrigeration technology. But conveyor systems in industry also make use of these properties. For example, when it comes to cooling food quickly down to low temperatures.

The excellent chemical resistance of polyethylene is characterised in particular by its high resistance in contact with acids, alkalis and solvents. In addition, polyethylene absorbs almost no moisture. These are important properties, especially in the production of precast concrete parts or in the construction industry. PE-HMW is also very often used in large chemical plants, for example to produce chemical containers or covers for chemical processing equipment.

Approvals for PE-HMW (PE500) in black

Polyethylene is food grade and is considered physiologically safe, which is why this plastic is used especially in the food industry such as large bakeries, the meat industry and in food packaging.

- Physiologically safe according to BfR

- Food conformity according to EU 10/2011

Standards for PE-HMW (PE500) in black

- REACH (EU Chemicals Regulation)

- RoHS (Regulation on the Prohibition of Hazardous Substances in the Electrical Industry)

- PAK (Directive on compliance with limit values for polyaromatic hydrocarbons)

We can supply other thicknesses, formats and colours of our PE-HMW sheets on request.

With our PE-HMW sheets in the standard format of 2.0x1.0 metres in thicknesses of 10mm-100mm, we cover almost all areas of application. However, if you need other thicknesses than those available in our online shop, please send us your request by email. We are also able to supply you with our black PE-HMW sheets in a format of 3.0x1.5 metres. Furthermore, it is possible to obtain the high-molecular PE500 sheets directly in the sizes you require. Simply send us your specific enquiry with all the necessary details, such as the required number of pieces, the dimensions for length and width in millimetres, as well as the desired thickness. Our sales staff will contact you immediately and send you your inexpensive, individual offer.

Individual milled parts made of black PE-HMW are possible on request.

We have modern CNC milling machines with three axes, which enable us to produce milled parts from our black PE-HMW sheets according to your design drawing. All information about our milling service can be found here.

Application examples for PE-HMW (PE500) in black

- The materials handling technology takes advantage of the low wear and good sliding properties of PE-HMW

- Thanks to its good chemical resistance and high impact strength, PE-HMW is often used in concrete construction

- PE-HMW is food safe and is therefore used in the food processing industry

- PE-HMW's low-temperature resistance of -100°C is used in warehousing and cold storage

- and many more

Processing PE-HMW (PE500) in black

PE-HMW (PE500) is very easy to process. Cutting our sheets made of PE500 can be done with simple tools like those used for cutting wood. This means that PE500 can be easily sawn, milled or drilled. Polyethylene turning, as well as punching, are other processing methods used for PE-HMW. Moreover, cutting can also be carried out with a water jet cutting system or a CO2 laser system.

For our black sheets made of PE-HMW, thermoforming as well as cold forming is a suitable method for the production of finished parts made of high-molecular-weight polyethylene with high density. In the industrial production of prefabricated plastic parts, thermoforming of polyethylene is also very often used, because as a thermoplastic, PE-HMW is well suited for so-called thermoforming.

Due to the very good resistance to chemicals and solvents, printing and sticking a film on the black PE-HMW sheets is not possible, as neither ink nor film adhere to this plastic. Gluing with conventional solvent-based plastic glue is also impossible with polyethylene. In our online shop, however, we offer the two-component adhesive S-Polybond PEprofi, which was specially developed for plastics that are difficult to bond, such as polyethylene (PE-HD, PE500, PE-1000).

Like all plastic sheets made of polyethylene, our black PE-HMW sheets are anti-adhesive. This means that PE cannot be glued with conventional adhesives and is therefore usually welded with a suitable welding rod to create a permanent bond between the individual polyethylene elements. We can also supply the appropriate PE-HD-HMW welding rod for welding our black PE-HMW sheets on request.

NOTE: As an engineering plastic, our PE-HMW sheets are only suitable for optical purposes to a limited extent and are supplied without a protective film.

- Additional Information

Additional Information

Product-ID 61020S Standard width 1000 Standart Length 2000 Thickness No Delivery Time Dispatch within 7 - 10 working days Plastic Polyethylene Material PE-HMW (PE-500) UV resistance not UV resistant Color Black Color accuracy Color similar to RAL color system RAL color code RAL9005 Color designation Jet black - Reviews

- Attachments