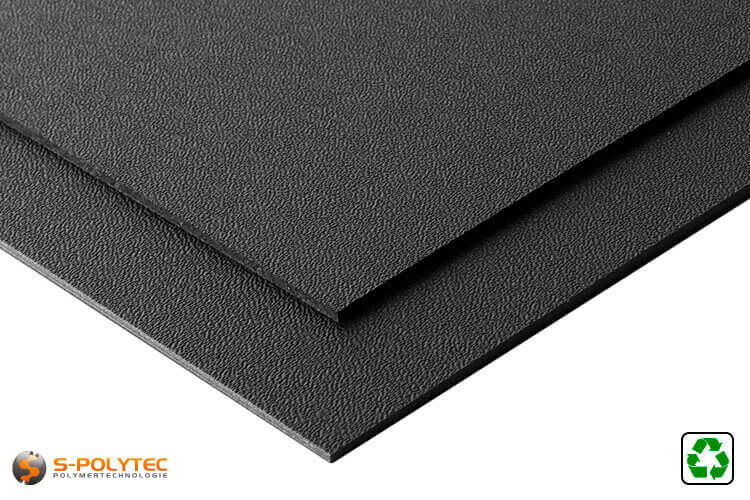

PE-HD Regenerate black grained on both sides 2x1 metre

The polyethylene sheets made from 100% recycled material (PE-HD reclaimed material) are available from us as standard sheets in 2x1 metre format with a grained surface on both sides at rock-bottom prices. The sheets with a medium grain are available in thicknesses of 10 mm and 15 mm. 100% recycled PEHD ✓ 100% quality Made in Germany ✓

The item is in stock

Dispatch within 2-3 working days

- Standard panels

- at pieces 0,00 € (Base Price 0,00 € / m2)

- at pieces 0,00 € (Base Price 0,00 € / m2)

- at pieces 0,00 € (Base Price 0,00 € / m2)

All prices include 19% VAT.

0,00 € / pc.

0,0000kg / pc.

All prices include 19% VAT.

- Description

PE-HD regenerated material grained on both sides in 2x1 metre format

100% single-variety ✓ 100% recycled ✓ 100% quality Made in Germany ✓

Our sheets made of PE-HD reclaimed material in black with surface graining on both sides have a length of 2000mm and a width of 1000mm in the standard format and are available in a thickness of 10mm or 15mm. These are solid sheets that are fully coloured throughout and not foam core sheets with coloured surfaces. Although the strong black of the panels is not produced to RAL, it is very similar to the colour deep black (RAL 9005). This results from the high proportion of carbon black, which contributes to the high colour fidelity of recycled sheets, which would otherwise not be guaranteed due to the mixture of different coloured recycled materials. In contrast to the recycled sheets in thinner thicknesses, the surfaces of the black PE sheets are grained on both sides, the texture of which is roughly reminiscent of grained leather. As a predominantly technical plastic, our PE-HD sheets are not finished with a protective film.

Quality doesn't have to stop at recycling - at least not with our recycling boards!

Made in Germany - that speaks for quality. Not only are the sheets extruded by a company based in Germany, but the recycling is also carried out entirely in Germany. We purchase the recycled material we use from selected plastics processors and also use our own offcuts to produce our PE-HD recycled sheets. The advantages are obvious, as we recycle our plastic waste in the most sensible way and can also ensure very favourable conditions for the production of the sheets. The resulting price advantage is of course also reflected in the price of our recycled sheets in the online shop, because environmental awareness and sustainability do not automatically have to go hand in hand with a significantly higher price, as many other brands and products suggest.

Properties of the grained PE-HD sheets made from recycled material

Our plastic sheets made of PE-HD reclaimed material are manufactured from PE-HD plastic waste that has been collected separately. As a result, the typical properties of the plastic are retained and can be equated with PE sheets made from virgin material. The very good chemical resistance, the good sliding properties and the high impact resistance are retained, meaning that the PE-HD recycling sheets can be used as a replacement for virgin PE-HD in the vast majority of applications without any problems. The temperature resistance with a temperature application range of -50°C and +80°C, as well as the physical density of 0.96 g/cm3 are identical. As a waterproof plastic, polyethylene does not absorb moisture. Not even if the sheets are used permanently in contact with water or under water. This property is also known as hydrophobic.

The surfaces of the black recycled sheets have a medium grain on both sides, making them the only polyethylene sheets, and indeed the only recycled sheets regardless of the plastic, to have this feature. We made this decision deliberately, as sheets of this thickness are also very frequently used in many branches of industry to delineate the path of travel within production facilities or as a separating device to protect machinery and equipment. The reason for this is the enormous impact resistance of HDPE and the very good chemical resistance, meaning that the PE sheets are very easy to clean using simple means, as nothing sticks to the surface. These are significant advantages, especially in the manufacturing industry, where high safety and hygiene standards must be maintained. It is perfectly possible to use the panels as wall panelling for the reasons mentioned and they provide effective impact protection, especially where there is heavy forklift traffic, but in most cases, panels with a lower thickness are sufficient for lining wall areas. The double-sided grain is not necessarily an advantage either. With our PE regenerates in standard format with a grained surface on one side, we also offer a favourable and sustainable alternative to comparable sheets made of virgin PE-HD for such applications.

Application examples for large-format recycled sheets made of PE-HD

The standard panels have a length of 2000mm and a width of 1000m. For large-format applications, such as extensive wall panelling or impact-resistant supports for workbenches, but also as impact protection for jetties and harbour basins. If, on the other hand, the boards are to be used in smaller dimensions, this is easily possible with simple means and tools for cutting wood. Our cutting service, where we cut the black recycled sheets made of recycled polyethylene directly to size for you, requires even less effort.

Act sustainably with recycled panels and save money at the same time!

Polyethylene is an extremely versatile plastic and is one of the most widely used thermoplastics in countless branches of industry for good reason. The plastic owes this not least to its many positive properties. It does not matter whether it is virgin or regenerated material. Only when used in the food processing industry, as well as for thermoforming, do the sheets lose out to comparable sheets made from virgin material, because although only pure plastic waste is used and cleaned, the smallest impurities cannot always be ruled out 100%. For transport and conveyor technology for already packaged foodstuffs, however, reclaimed material is definitely worth considering, because unlike many products where terms such as recycling or sustainability contribute to a significant price increase, our recycled sheets are significantly cheaper than standard sheets made from virgin PE in 10 mm or 15 mm thicknesses.

Polyethylene is a very impact-resistant plastic that does not break even when subjected to very strong blows and impacts. It is hardly surprising that the black sheets are used to protect garages, narrow spaces in underground car parks or in warehouses with forklift traffic to protect walls and vehicles. Our grained regenerated polyethylene sheets are ideal for this purpose, as they are significantly cheaper than sheets made from virgin material and offer the advantage that minor scratches and bumps are less noticeable due to the grained surfaces. PE is also extremely suitable as impact protection in and under water, as polyethylene is considered hydrophobic, which means that the plastic does not absorb water. The plastic sheet protects boats and ships as well as harbour walls, jetties or lock walls from damage caused by bumps, which cannot always be completely avoided, especially in the case of higher wave movements.

The recycling boards are a very inexpensive and reusable option for lining the cargo area of vans and articulated lorries or for using the boards as vertical protection between the individual pallets, furniture and freight forwarding goods to optimise load securing and protect the load from transport damage. The temporary covering of individual panels can also be useful if the boxes stacked on them are in danger of tipping over when cornering or braking. In trailer construction, the sheets with their good sliding properties are used to lay out the floor area as well as to line the brackets and offer good stability and impact resistance, especially in high thicknesses. However, the solid plastic sheets are not suitable as a replacement for an existing floor made of screen printing plates. The construction should have sufficient load-bearing capacity so that the panels do not sag or bend under high loads despite their high thickness.

- PE-HD recycled sheets in 2x1 metre format are ideal for large-format machine covers

- PE panels provide effective wall protection in garages, underground car parks and production halls

- Thanks to their good sliding properties, the sheets are ideal for conveyor technology in many branches of industry

- Due to their high thickness, the large recycling sheets are particularly suitable for container construction

- The waterproof sheets made of PE regenerate are ideal as impact protection in harbour and lock basins

- and many more

Processing of standard sheets made of PE-HD reclaimed material

Cutting PE-HD recycling sheets to size In very few cases are the recycled sheets in the 2x1 metre format used without further processing. Cutting the thick boards to size is therefore one of the most common methods of further processing in order to bring the standard boards into the desired size or shape. Due to the panel thickness of 10 mm and more, machining processing techniques are most suitable here, as such thick panels can hardly be cut to size with a simple knife or laser. Sawing or routing thermoplastics can also be realised with simple tools, as long as care is taken not to generate too much heat. You can achieve this by significantly reducing the feed rate and speed of the machine, as this results in less friction and the saw blade or router bit, as well as the surface of the cutting edges, do not heat up so quickly so that the sawdust does not fuse with the cutting edge. A medium coarse toothing is best suited for this, as this results in a precise cutting pattern in contrast to a coarsely toothed saw blade. A saw blade that is too fine, such as those used for cutting metal, will heat up too quickly. A hand-held jigsaw is ideal for small cuts, cut-outs and round cuts. A circular table saw or a hand-held circular saw with a depth stop, on the other hand, is well suited for straight sections of polythene sheets.

NOTE: As an alternative to the standard sheets, you can also buy the PE sheets grained on both sides directly cut to size and save yourself the effort. It gets even better, because we don't charge for the offcuts. You only pay for the cutting, so you can also save money.

Drilling PE-HD recycling sheets Drilling polythene is as easy as drilling soft wood, with two exceptions. The first difference is that an HSS drill bit is more suitable than a wood drill bit. This peels through the plastic more easily and precisely due to the drill geometry. With a special HK drill bit, which is specifically designed for drilling plastics with its smaller point angle, even more precise drill holes are possible. The second difference is the drilling speed. Wood does not melt, so a higher speed can be selected for drilling. When drilling plastic, however, too high a speed has the negative side effect that both the drill bit and the edge of the hole itself heat up too much. This can cause the melting temperature of the plastic to be exceeded and the chip to fuse with the drill hole. A low speed with reduced pressure on the drill tip reduces the risk considerably.

Bonding PE-HD recycled sheets For bonding polyethylene, a special adhesive such as our S-Polybond PEprofi is required. This is a two-component adhesive consisting of resin and hardener, which bonds PE together securely and firmly. PE cannot be bonded with standard adhesives. Our PE regenerate is no exception. Solvent-based adhesives are particularly unsuitable here, as polyethylene is highly resistant to solvents. It is not for nothing that a dosing bottle made of this plastic is used for most adhesives.

Technical data of our PE-HD recycled sheets in deep black

- Material: Polyethylene regenerate (PE-HD, recycled material)

- Colour: Black (similar to RAL9005, deep black)

- Surface: Grained on both sides (medium grain)

- Plate format: 2000mm x 1000mm

- Physical density: 0,96 g/cm3

- Modulus of elasticity: 1100 MPa according to DIN EN ISO 527

- Impact strength: Without breakage according to DIN EN ISO 179

- Notched impact strength: 16 kJ/m2 According to DIN EN ISO 179

- Shore hardness: 65 according to DIN EN ISO 868

- Food conformity: Nee

- Temperature resistance: -50 °C up to +80 °C

- Chemical resistance: Excellent

- Fire behaviour: B2 (normally flammable) according to DIN 4102

- UV-resistance (colour): UV stabilised

Disposal of reclaimed PE plastic

Regenerates are a recycled plastic. However, this does not mean that it cannot be recycled again. As long as it is collected by type and free from coarse dirt, the recycling cycle can be repeated almost as often as required, thus permanently avoiding the extraction of raw materials for the production of plastic sheets.

As a private individual, you are unlikely to accumulate large quantities of plastic, so disposing of it in a recycling bag or yellow bin is the easiest way to recycle offcuts. This is in stark contrast to companies that buy and process standard sheets in large quantities. Here, collecting the offcuts by type can also be worthwhile for a purchase, which can be realised under certain conditions via one of our partner companies.

NOTE: PE is a technical plastic that should not be used for optical purposes and is supplied without a protective film. Small surface scratches before and during processing cannot be completely avoided with polyethylene, but are not very noticeable due to the surface grain on both sides.

- Additional Information

Additional Information

Product-ID 60921S Standard width 1000 Standart Length 2000 Thickness No Delivery Time Dispatch within 2-3 working days Plastic Polyethylene Material PE-HD Regenerat (Recyclingmaterial) UV resistance not UV resistant Color Black Color accuracy Color similar to RAL color system RAL color code RAL9005 Color designation Tiefschwarz - Reviews

- Attachments