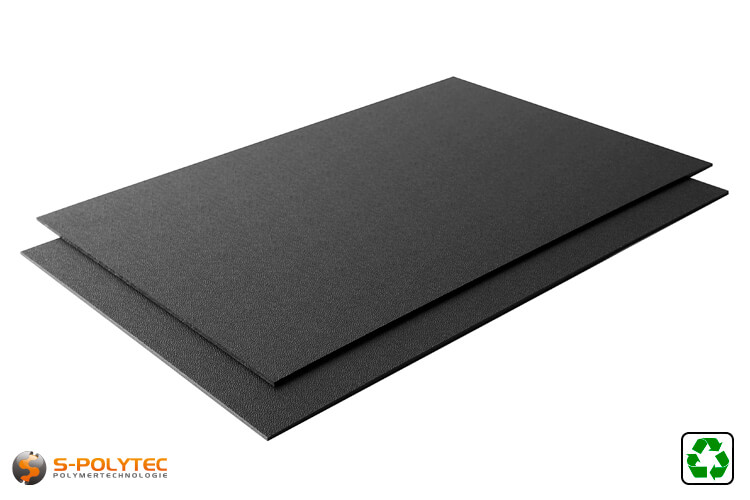

PE-HD recyclate black grained 2x1meter

Buy polyethylene sheets made of PE-HD regenerated in black as standard sheet in the format 2x1 meter grained surface at lowest prices. The recycled sheets with a one-sided medium graining are available in 2mm to 5mm thickness. 100% recycled material ✓ 100% quality Made in Germany ✓

The item is in stock

Dispatch within 2 - 3 working days

- Standard panels

- Request a sample

Request up to three free samples.

Dimensions of the samples approx. 200mm x 100mm

- at pieces 0,00 € (Base Price 0,00 € / m2)

- at pieces 0,00 € (Base Price 0,00 € / m2)

- at pieces 0,00 € (Base Price 0,00 € / m2)

All prices include 19% VAT.

0,00 € / pc.

0,0000kg / pc.

All prices include 19% VAT.

- Description

PE-HD regrind as standard panels in 2x1 metre format

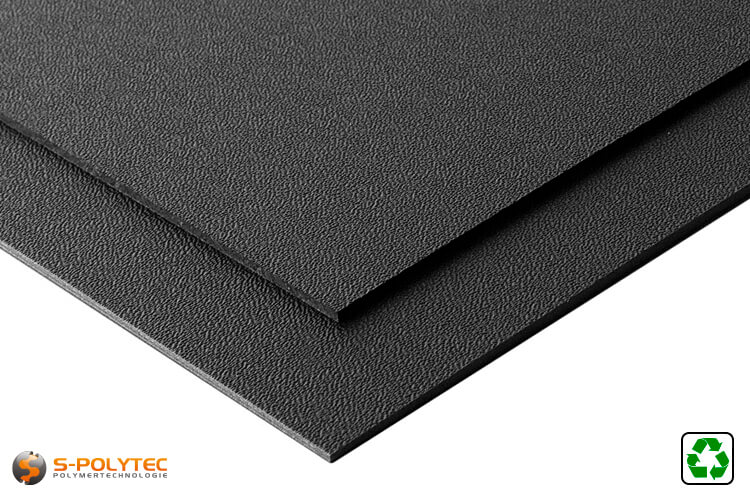

Our standard panels made of PE-HD regrind (recycled material) in black have a length of 2000mm and a width of 1000mm and are available in 2mm to 5mm thickness. The plastic sheets are solid sheets and not PE sheets with a foamed core. The colour of the sheets is similar to RAL9005 (Jet black) and is identical on the surfaces and cut edges, because the plastic sheets are completely black. The surface is machine-smooth on one side and has a medium grain on the other side, the surface structure of which roughly resembles a grained leather surface. Our PE-HD sheets made of recycled plastic are not equipped with a protective film.

NOTE: Should you require our PE-HD sheets made of regenerated material in other thicknesses, this is possible without any problems, even with a minimum quantity of only 500 kg per thickness. Simply send us an enquiry by e-mail or give us a call.

We use our own waste material for the production of recycled polyethylene sheets, so we can have them produced at very low cost. In addition, the very high purchase quantity from our extruder also contributes to the fact that we purchase at very favourable conditions. This means that our plastic sheets are not only very cheap to buy, but also in our online shop. Due to the constant stocking of our standard sheets made of grained regenerated PE, very short delivery times are guaranteed. As a rule, our standard sheets are packed safely on a pallet and picked up by our partner forwarding agency on the next working day after receipt of the order.

Characteristics of the black PE-HD sheets made of recycled material

100% Polyethylene - 100% Recycling-material - Made in Germany

Our PE-HD recycling sheets are manufactured from PE-HD plastic waste collected by type, so that their properties are comparable to those of PE sheets made from new material. Therefore, the values for the physical density of 0.96 g/cm3 or the temperature range of use, which lies between -50°C and +80°C, are identical. There is also no need to make any concessions in terms of chemical resistance, good sliding properties or impact resistance when using our regenerates. Due to the high soot content, the sheets are also UV-stabilised and can therefore also be used for outdoor applications. Polyethylene is a waterproof plastic that does not absorb any moisture and can also be used permanently in contact with water thanks to its hydrophobic properties.

In contrast to our black PE-HD sheets in the standard format with a smooth surface on both sides, which we supply as virgin material in many thicknesses from 1mm - 100mm, our PE-HD recycling sheets have a one-sided grain. This is a particular advantage for optical applications, because PE has a low Shore hardness and can therefore scratch more easily than other plastics with a higher surface hardness. Thanks to the textured surface on one side, slight scratches are less noticeable than on a smooth standard plate made of PE plastic.

Environmental awareness does not have to be expensive - at least with our recycled panels!

Polyethylene is one of the most commonly used plastics. PE owes this to its many positive properties. Far too often, new material is used unnecessarily, although the use of PE sheets made of recycled material would also be possible without hesitation. In this respect, regenerates can score points with two very clever arguments, because on the one hand, raw materials can be dispensed with and on the other hand, plastic sheets made of recycled material are significantly cheaper than comparable sheets made of virgin material. For the production of the recycled sheets, pure plastic waste of PE-HD is used, which has the same properties before and after recycling. Many companies let the environmental awareness cost them dearly by selling the products at a higher price. We recycle our waste ourselves and pass the price advantage on to you.

Maximum flexibility with standard panels - simply cut to size yourself as required!

With our standard panels measuring 2000mmx1000mm, you can not only erect flat panelling or covers in no time at all, but you can also cut them to size yourself according to your requirements without being restricted to rectangular formats. Simple hand tools, such as a jigsaw or circular saw and corresponding saw blades with medium toothing are sufficient for this purpose.

Application examples for grained PE-HD recycling sheets

Recycled sheets made of PE plastic are suitable for most applications where PE sheets made of virgin material are usually used, because after all, they are the same plastic with the same properties. However, there are also restrictions which we do not want to withhold from you. The first essential aspect is that even with the greatest care during recycling, it cannot be ruled out that small impurities from foreign plastics may be present, which is why recycled sheets are not suitable for direct contact with food. For the same reason, the production of thermoformed parts is not recommended, but is nevertheless very often used, e.g. for transport packaging.

Polyethylene is characterised by its very good impact strength. This property contributes to the fact that this plastic is extremely suitable for protecting walls and vehicles in underground car parks, vehicle parking spaces or even production halls with forklift trucks. Our grained regenerates made of polyethylene can be used for this purpose because they are not only much cheaper than sheets made of virgin material, but also have the advantage that minor scratches and bumps on the grained surface are not noticed so quickly. The same also applies to the covering of machine components and industrial plants, because here too impact-resistant plastic sheets are often used.

In the transport sector, e.g. for forwarding agents and removal companies, polyethylene is often used to protect sensitive goods. This is not only due to the very favourable price of the lightweight panels, but also to the very good sliding properties, which prevent damage to the goods by positioning the plastic panels between the furniture or equipment. In addition, the panels can be reused as transport protection almost as often as required.

- PE-HD regenerated sheets in the 2x1 metre format are very suitable for flat panelling to protect walls

- The standard panels are ideal for blanks of any shape and can be easily processed with simple tools

- The recycled sheets made of cost-effective PE-HD are perfectly suited as protective sheets for transporting furniture or equipment

- The attractive appearance of the grained surface is ideal for cladding and covering machines and workshops

- and much more

Processing of plastic sheets from PE-HD regenerated

Cutting PE-HD regrind to size

In order to cut the standard panels in the 2x1 metre format to the required final size, a great many processing methods can be used, because the recycled panels made of PE plastic are very easy to process. Very small thicknesses can be cut with a sharp knife, for example. For higher thicknesses, however, all the techniques used for wood cutting are also available. The boards can be sawn, milled, planned or ground. All conventional tools used in woodworking are suitable for this purpose. The only difference worth mentioning is that when sawing or milling, both the feed rate and the speed should be lower so that the chip produced does not melt into the cut edge, because too high speeds result in too much material heating.

Polyethylene can also be cut very well with a CO2 laser. Depending on the thickness, the laser speed and the power of the laser should be adjusted. The same applies to cutting with a water jet cutting machine, but here the water pressure of the jet must be adapted to the existing thickness.

NOTE: As an alternative to the standard panels in the 2x1 metre format, we offer the PE-HD recycling panels also cut to size directly in your desired size.

Drilling PE-HD regrind

In order to screw the UV-stabilised panels to the wall as cladding, for example as wall and ram protection, it is advisable to pre-drill the fixings. To drill the holes, however, a normal cordless screwdriver with a metal drill in the desired size is sufficient. Also when drilling, the speed should be reduced considerably. You should also be careful not to exert any pressure on the drill. Otherwise the plastic could break when the drill emerges. Thus, with the black PE plates, perforated plates can also be produced in no time at all, for example as ventilation covers on machines.

Bond PE-HD regrind

Bonding polyethylene is a challenge in itself, because PE-HD cannot be bonded with conventional adhesives due to its very good chemical resistance. However, with a special adhesive on a 2-component basis, such as our Polyethylene adhesive S-Polybond PEprofi, a permanent and secure bond is still possible. The adhesive of our own brand has been specially developed for bonding polyethylene (PE-HD, PE-HMW, PE-UHMW) and is also perfectly suitable for bonding our recycling sheets made of PE plastic.

Thermoforming PE-HD regrind

Polyethylene is a thermoplastic, which as such can easily be formed into the desired shape by so-called deep-drawing to produce finished plastic parts. This is a widely used process, especially in industrial series production, which can be carried out quickly and easily and is therefore very cost-effective. For plastic sheets made of PE-HD recycled material, this process is also used very often, e.g. for the production of disposable packaging or transport containers, trays, plant pots and much more. However, this is only suitable for deep-drawn parts without too high demands on appearance or mechanical strength. When recycling plastics, it can never be completely ruled out that there are no inclusions of foreign substances. This would be visible during deep drawing, especially with low sheet thicknesses or a high aspect ratio, and can also affect the quality of the deep drawn part.

Note: We do not guarantee the quality of thermoformed parts made of our PE-HD regenerated material.

Disposal of regenerated PE plastic

Polyethylene can be recycled as often as required if the plastic is collected separately. In the recycling process, the plastic waste is cleaned and then shredded and ground so that new plastic sheets can be produced from the ground material thus obtained. Even semi-finished plastic products made from recycled material can be processed into regenerated material again, so that the extraction of raw materials for plastic production can be dispensed with. In addition, the recycling cycle means that less plastic waste is thermally recycled in waste incineration plants, which means that valuable raw materials are irretrievably lost.

Smaller quantities - also known as normal household quantities - can be disposed of in the recycling bin or the yellow recycling bag so that they can be recycled later. For larger quantities, we recommend that you contact recycling companies or extractors who will buy the plastic waste for a small fee. However, the prerequisite for a purchase is that the plastic waste is collected separately and contains only PE-HD. If other plastics are contained, this not only reduces the quality of the regenerated material, but may also cause damage to the extrusion line.

NOTE: Our black polyethylene recycling sheets are supplied without protective film, so we recommend that you handle and process them with care to avoid damage and scratches to the surface. Thanks to the one-sided surface structure, minor scratches or bumps on the grained side are hardly noticeable.

- Additional Information

Additional Information

Product-ID 60920S Standard width 1000 Standart Length 2000 Thickness No Delivery Time Dispatch within 2 - 3 working days Plastic Polyethylene Material PE-HD Recyclate (recycling material) UV resistance UV stabilized Color Black Color accuracy Color similar to RAL color system RAL color code RAL9005 Color designation Jet black - Reviews

- Attachments